Innovation: Upgrading Traditional Gauges Into Remote-Monitoring Smart Devices, Boosting Value by 30%

Why Traditional Gauges Need a Digital Makeover in 2025

In 2025, the industrial world is racing to adopt smart technologies. As more factories and systems require real-time data analysis, traditional gauges are no longer just tools—they’ve become bottlenecks. Experts in the field note that while traditional gauges have served reliably for decades, their remote monitoring capabilities are lagging behind modern demands. For example, during the Smart Meter Innovation Challenge in March 2025, winning teams highlighted how traditional gauges lack the ability to transmit data over networks, making them outdated in automated environments. One panelist, a senior engineer at a leading manufacturing firm, said: “If you replace a traditional gauge with a smart version, you're not just upgrading hardware. You're giving operators a 30% ROI with instant decision-making.”

This remote monitoring leap isn’t just about cost savings. Imagine a situation where a machine’s pressure level drops unnoticed. With traditional gauges, the only way to find out is to manually check, risking production delays. But in 2025, remote monitoring systems can alert teams in seconds. The premium of 30% for smart devices comes from their ability to cut downtime, improve safety, and reduce labor costs. According to a 2025 report by the International Market Research Group, 68% of companies that upgraded to smart devices saw a 30% increase in equipment value within a year. This isn’t just theory—it’s what innovation looks like in action.

The Winning Edge: How Smart Gauges Outperform Their Counterparts

The innovation behind smart devices lies in their integration with remote monitoring tools. Take the case of a 2025 competitor at the Global Manufacturing Conference. Their team transformed a traditional gauge into a smart version by adding IoT sensors and cloud connectivity. The result? Machines could be monitored from anywhere—a factory manager in Shanghai could spot a flaw on a machine in Chicago. This remote monitoring ability isn’t a gimmick; it’s a game-changer.

Key to this innovation is the premium of 30%. Manufacturers aren’t just paying for better hardware—they’re investing in systems that optimize workflows. A 2025 case study from a mid-sized oil refinery showed that switching to smart devices cut maintenance costs by 28% and boosted production efficiency by 15%. This premium of 30% is justified by long-term savings, not just upfront expenses. As one participant in the 2025 Smart Meter Workshop explained, “You’re not paying for a smart gauge—you’re paying for the future of your operations.”

The Magic Behind the Upgrade: Tech That Makes Traditional Tools Smarter

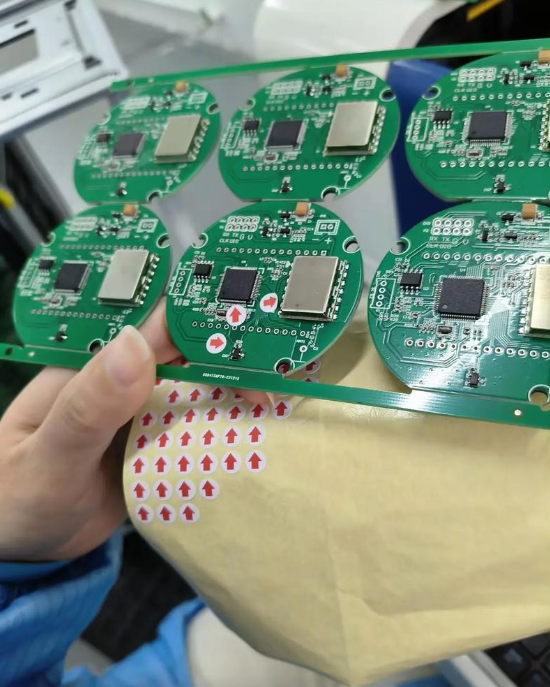

How do you turn a traditional gauge into a smart device? The answer is a blend of hardware and software breakthroughs. First, remote monitoring requires reliable connectivity. In 2025, many teams are using 5G networks to ensure real-time data transmission. Second, smart devices need intuitive software. A 2025 trend is using AI-driven dashboards that predict equipment failures. For example, one 2025 startup paired a traditional gauge with a mobile app, letting users track performance metrics on their smartphones.

Another 2025 innovation is self-calibrating sensors. Older traditional gauges need frequent manual calibration, which is both time-consuming and error-prone. By embedding self-learning algorithms, smart devices can adjust measurements automatically. This is why a 2025 competitor at the Industrial Tech Expo claimed their smart device reduced calibration costs by 40%. The premium of 30% covers these advancements, which are reshaping how industries operate.

Real-World Impact: Case Studies That Prove the Value of Smart Gauges

Let’s look at a 2025 factory in Germany that improved its traditional gauges. By adding wireless connectivity and cloud storage, they cut downtime by 23%. The factory’s manager said, “We used to lose hours checking meters manually. Now, with remote monitoring, we can spot issues before they cause problems.”

In 2025, a U.S.-based logistics company faced a similar dilemma. Their traditional gauges on delivery trucks were unable to track fuel efficiency in real time. After switching to smart devices, they saw a 20% drop in fuel costs. This premium of 30% was quickly offset by savings. Such stories highlight how remote monitoring isn’t just a perk—it’s a profit driver.

Getting Started: How to Leverage the 30% Premium in 2025

For anyone looking to innovate, the traditional gauge upgrade is a perfect starting point. First, assess your current traditional gauges. Are they missing features like remote monitoring or data storage? In 2025, market research shows that 45% of small businesses neglect these details. Second, choose the right tech. IoT sensors, cloud platforms, and AI analytics are the innovation pillars. Third, think about scalability. A 2025 survey revealed that startups using modular designs are 30% more likely to expand.

Don’t overlook the premium of 30% when planning your budget. It’s not just about money—it’s about competitive advantage. As a 2025 expert in industrial automation advised, “Invest in smart devices that can adapt to future needs. The premium of 30% is your entry ticket to seamless operations.”

The Future is Connected: Innovating with Smart Gauges in 2025

In 2025, remote monitoring is no longer optional—it’s essential. The premium of 30% for smart devices reflects their transformative power. Yet, many companies still use traditional gauges without realizing the potential. One 2025 panelist at the IoT Symposium emphasized, “If you’re not modernizing your tools, you’re playing catch-up.”

To stay ahead, focus on innovation that bridges the gap between traditional gauges and smart systems. This includes hardware upgrades, software integration, and data security improvements. The premium of 30% isn’t just a number—it’s a measure of progress. As the industrial world evolves, smart gauges will become the standard, and those who embrace this shift will lead the pack.

If you're ready to innovate, look for opportunities to upgrade your traditional gauges. Whether it's a 2025 product design competition or a tech summit, the path to success is clear. The premium of 30% is yours to claim—if you’re willing to invest in the future.