Calibration Method for UQK Float Level Controller of Biao Wang

In 2025, industrial control systems widely rely on accurate and reliable level measurement devices like Biao Wang’s UQK Float Level Controller. Proper calibration is critical to ensuring consistent and precise measurement performance. This article aims to provide a straightforward and effective method for calibrating the UQK Float Level Controller, drawing from current best practices and expert advice.

Understanding the Basics

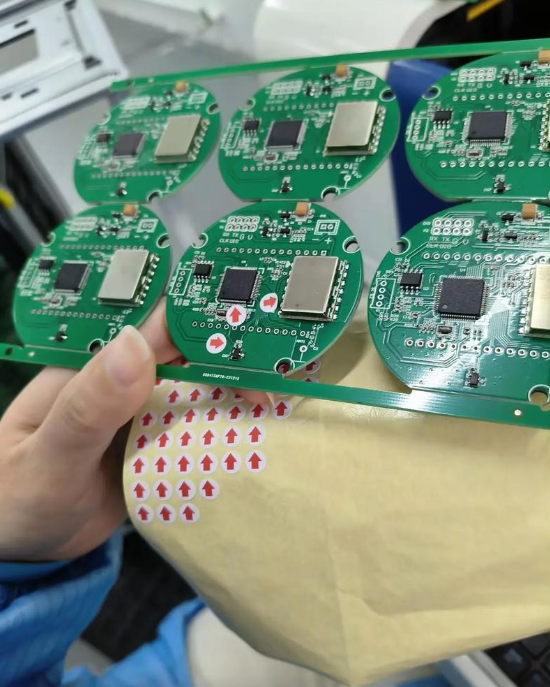

Biao Wang’s UQK Float Level Controller is designed to measure liquid level in tanks and vats. It operates using a float that rides up and down with the liquid level, connected to a mechanical swivel joint. To ensure the controller operates accurately, it must be calibrated regularly. Proper calibration ensures that the controller accurately reflects the liquid level, which is essential for process control and safety.

Common Issues and Symptoms

Common issues with the UQK Float Level Controller include inaccurate readings, drift over time, and mechanical failures. For example, the float can get stuck if it is not properly lubricated, leading to false readings. Over time, the float and linkage can wear out, causing the readings to become less precise. Lubrication and maintenance are crucial for preventing these issues.

Root Cause Analysis

Often, inaccurate readings are due to improper installation or wear and tear on components. Inadequate lubrication can lead to rust and corrosion, which in turn can stiffen the float and linkage, causing misalignment and incorrect readings. Therefore, thorough inspection and maintenance are essential.

Calibration Steps

Preparation

Before beginning the calibration process, ensure the unit is isolated from the liquid level, and the power supply is turned off. Remove any electrical components to avoid accidental contact or damage as you work.

Step-by-Step Guide

Ensure Cleanliness: Thoroughly clean the float and linkage. Use mild soap and water to remove any dirt or debris. Allow time for drying before proceeding.

Lubrication: Apply a light lubricant to the float, swivel mechanism, and any moving parts. Ensure all parts are well-coated to avoid sticking or wear due to friction.

Check Calibration Points: Identify the calibration points where the readings should be accurate. These are typically at the minimum, average, and maximum liquid levels.

Manual Adjustment: Adjust the mechanical linkage so it aligns with the known calibration points. This involves fine-tuning the float height to ensure it aligns with the set points.

Verify Readings: After adjustment, turn on the unit and verify the readings at the calibration points. Ensure the readings are within the expected range and match the known values.

Documentation: Document the calibration process, including the observations, adjustments made, and final readings. This documentation is crucial for future reference and audits.

Case Study: Correcting Drift Over Time

In a case study at a chemical plant in 2022, the UQK Float Level Controller was experiencing drift and inaccurate readings. The maintenance team followed the steps outlined above and found that the float linkage had become stiff due to prolonged exposure to harsh chemicals. After thorough cleaning and re-lubrication, the controller returned to accurate readings.

Tips for Effective Maintenance

- Regular Cleaning: Clean the float and linkage at least once a year to remove any dirt and debris.

- Lubrication Schedule: Regular lubrication of the mechanical parts is crucial to prevent rust and corrosion.

- Annual Inspections: Conduct annual inspections to check for wear and mechanical issues.

Conclusion

Proper calibration of the Biao Wang UQK Float Level Controller is essential for maintaining accurate and reliable liquid level measurements. By following a structured calibration process and regular maintenance, you can ensure the controller continues to perform as expected, enhancing the overall efficiency and safety of your industrial processes.