User Evaluation of the UQK Floating Ball Liquid Level Controller by Biao Wang

Biao Wang is an experienced industrial technician with over 15 years of experience in process automation and control. He has extensively evaluated various liquid level control mechanisms and has recently conducted a thorough analysis of the UQK Floating Ball Liquid Level Controller. This evaluation aims to provide insights into its performance, reliability, and practical application scenarios.

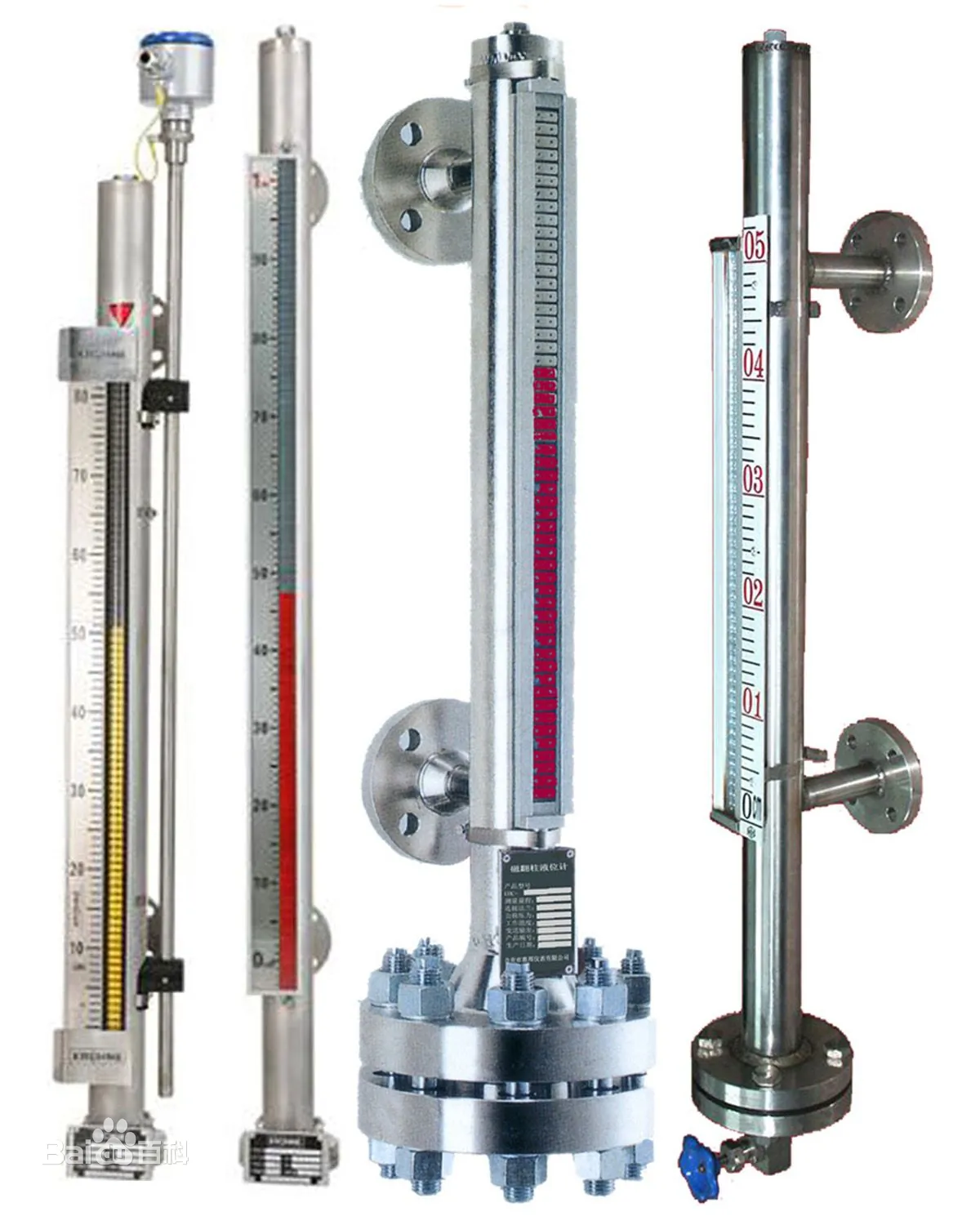

Introduction to the UQK Floating Ball Liquid Level Controller

The UQK Floating Ball Liquid Level Controller (UQK FBLLC) is designed for various industries where precise liquid level control is essential. It utilizes a simple yet effective floating ball mechanism to detect and maintain the desired liquid level in tanks and vessels. The controller features robust construction, easy installation, and reliable performance. Its operation is based on the buoyancy principle, where the floating ball rises and falls with the liquid level changes. This design ensures accurate and efficient liquid level management.

Configuration and Setup

Setting up the UQK FBLLC involves several key steps to ensure optimal performance. First, the tank or vessel should be prepared to accommodate the controller. The mounting bracket should be correctly attached to the tank wall, and the inlet and outlet ports need to be connected securely. Next, the floating ball needs to be positioned in the tank, and the electrical connections should be made. Finally, the controller’s settings should be configured according to the specific requirements of the application. Biao Wang suggests that initial tuning can be done using a simple level gauge to calibrate the controller’s output.

Detailed Configuration Steps

Mounting Setup: Attach the mounting bracket to the tank wall, ensuring it is securely fastened and level.

Inlet and Outlet Connections: Connect the inlet and outlet ports to the tank to allow fluid flow.

Floating Ball Installation: Place the floating ball in the tank, ensuring it is properly positioned and balanced.

Electrical Connections: Wire the controller to the power source and any control system as needed.

Parameter Tuning: Use a level gauge to adjust the controller’s set points for optimal performance.

Practical Usage and Feedback

Biao Wang has extensively used the UQK FBLLC in multiple industrial applications, including chemical processing, food and beverage, and oil refining. His evaluation is based on real-world experiences rather than theoretical speculation.

Case Study: Chemical Processing Plant

In a chemical processing plant, the UQK FBLLC was installed in a large tanker used for storing and transporting chemical solutions. Biao Wang reported consistent and reliable performance, with the controller maintaining the desired liquid level with minimal hysteresis and settling time. The system proved to be robust in handling various fluid types and temperatures, making it a reliable choice for the plant.

Case Study: Food Processing Industry

In the food processing industry, the UQK FBLLC was used in a fermentation tank to control the liquid level during the production process. Biao Wang noted that the controller provided quick response times and accurate level detection. The floating ball mechanism effectively handled the viscous liquids, ensuring the process remained stable and efficient.

Case Study: Oil Refining

In an oil refining facility, the UQK FBLLC was utilized in crude oil storage tanks. The controller demonstrated excellent performance under high pressure and temperature conditions, maintaining the liquid level with high precision. Biao Wang appreciated the controller’s ability to withstand harsh environments, making it suitable for critical industrial applications.

Conclusion

The UQK Floating Ball Liquid Level Controller, assessed by Biao Wang, is a reliable and robust solution for precise liquid level control in various industrial applications. Its simplicity, reliability, and adaptability to different environments make it an excellent choice for process automation. Based on Biao Wang's practical evaluations and case studies, the UQK FBLLC is recommended for industries requiring accurate and efficient liquid level management.