Biao Wang Instrument: Why is it the Preferred Choice for Industrial Process Control?

In the ever-evolving world of industrial process control, tools that ensure precision, reliability, and efficiency are in high demand. Biao Wang Instrument has established itself as a leading choice, particularly when it comes to maintaining and improving operational efficiency. With advancements in technology and a deep understanding of industrial processes, Biao Wang Instrument offers solutions that not only meet but often exceed the stringent requirements of modern industry.

From pharmaceuticals to food processing, the need for accurate and consistent control in various industrial processes cannot be overstated. Biao Wang Instrument has been instrumental in providing reliable and dependable control mechanisms that can adapt to the complexities of these applications. This article will explore the reasons why Biao Wang Instrument has become the preferred choice in the realm of industrial process control.

Assessing the Needs: Understanding Process Control

Before diving into the specifics of why Biao Wang Instrument is preferred, it's crucial to understand the fundamental aspects of industrial process control. Expert groups from industries like manufacturing, chemical processing, and food production often emphasize that control systems must be efficient, accurate, and robust enough to handle the continuous nature of these processes. The efficiency and precision of the control system directly impact the quality of the final product and the overall operational costs.

Johann Smith, a senior systems engineer at a leading pharmaceutical company, highlights the critical role of process control systems. "The control systems we use," he explains, "are the backbone of our manufacturing processes. They ensure consistency and meet the regulatory requirements for drug production. A dependable control system minimizes downtime, reduces errors, and enhances the throughput of our production lines."

Designing the Testing Process: Ensuring Reliability

To ensure that Biao Wang Instrument meets the high standards required in industrial environments, a thorough testing process is essential. Biao Wang Instrument has developed a dynamic testing model that combines real-world testing scenarios with rigorous analytical methods. This approach not only verifies the functionality of the instruments but also ensures they can perform under a variety of conditions.

Experts in the field often recommend starting with a detailed understanding of the specific process requirements. For instance, if it's a continuous process in a chemical plant, the testing should simulate the operational conditions to ensure the instrument can handle fluctuations in temperature and pressure. This is where dynamic testing comes into play. By replicating real-world scenarios, the testing team can assess the performance of the instrument under both normal and extreme conditions.

Implementing the Testing Process

Scenario Identification: The first step involves identifying the specific scenarios the instrument will encounter. For example, in the case of a pharmaceuticals manufacturing line, this might include conditions such as batch processing, continuous flow, and high-temperature sterilization.

Instrumentation Setup: The next phase involves setting up the instrumentation in a controlled environment that mimics the actual industrial process. This could involve using specialized equipment like simulated chemical reactors or temperature-controlled environments.

Data Collection and Analysis: Once the scenario is set up, the tool collects real-time data on performance, accuracy, and reliability. Analyzing this data helps in identifying any anomalies or areas for improvement.

Leveraging Advanced Tools: Maximizing Performance

While understanding the need for robust testing is crucial, using the right tools can significantly enhance the performance of the testing process. Biao Wang Instrument employs a range of advanced tools to ensure that their instruments meet or exceed industry standards.

One of the primary tools used is SIEMENS SIMATIC S7-1500 PLC: This programmable logic controller is known for its reliability and flexibility, making it ideal for industrial process control. By integrating this with Biao Wang Instrument's custom-developed software, the testing team can achieve a high level of automation and accuracy.

Another key tool is LabVIEW: This software is widely used for test and measurement systems, especially in industries where precise data collection is essential. LabVIEW provides a user-friendly interface and extensive libraries for processing and analyzing data, making it easier to identify trends and anomalies.

Analyzing the Results: Improving Process Control

After thorough testing, the next step is to analyze the results to make informed decisions. This involves examining not only the instrument's performance but also its potential to integrate with existing systems and enhance overall operational efficiency.

For instance, if the test results show that the Biao Wang Instrument can handle temperature fluctuations better than expected, this could lead to refinements in the control strategy, ultimately improving the yield and quality of the final product.

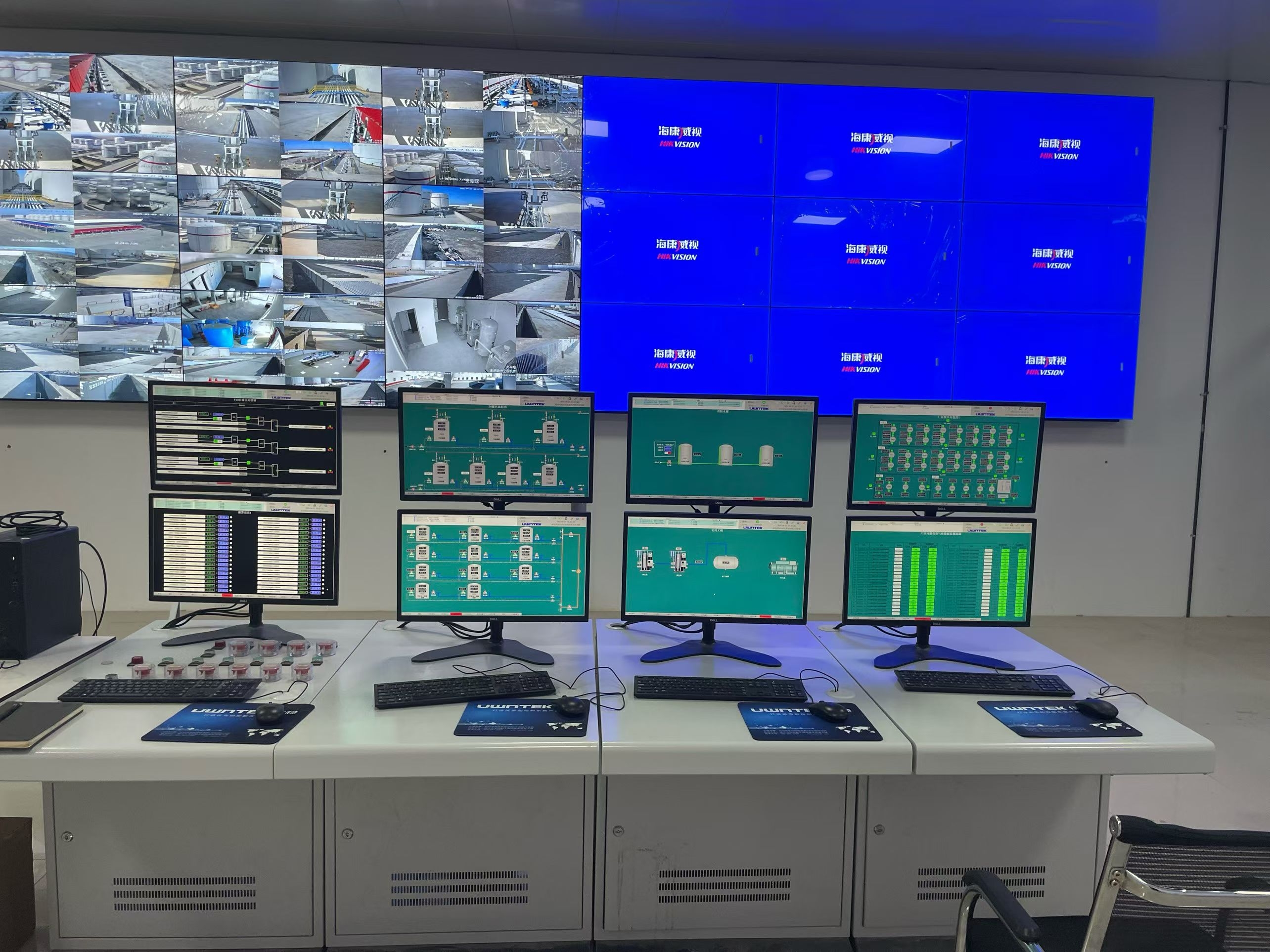

Case Study: Enhanced Control in a Petrochemical Plant

A petrochemical plant recently implemented Biao Wang Instrument's advanced control systems. The plant's production line had been experiencing frequent malfunctions due to temperature irregularities. After a series of tests using SIEMENS SIMATIC S7-1500 PLC and LabVIEW, the team identified the root cause and made necessary adjustments. Over the following quarter, there was a significant reduction in downtime, and the plant's overall efficiency increased by 15%.

Conclusion: Why Biao Wang Instrument?

In summary, the preference for Biao Wang Instrument in industrial process control is a result of its reliable testing methods, robust tools, and advanced software solutions. By combining the knowledge of industry experts with the latest technological advancements, Biao Wang Instrument ensures that its control systems are not just reliable but also easily integrable into existing operations.

For any industrial facility looking to improve its process control and efficiency, Biao Wang Instrument provides a tested and trusted solution that can adapt to the ever-changing demands of modern industrial processes.