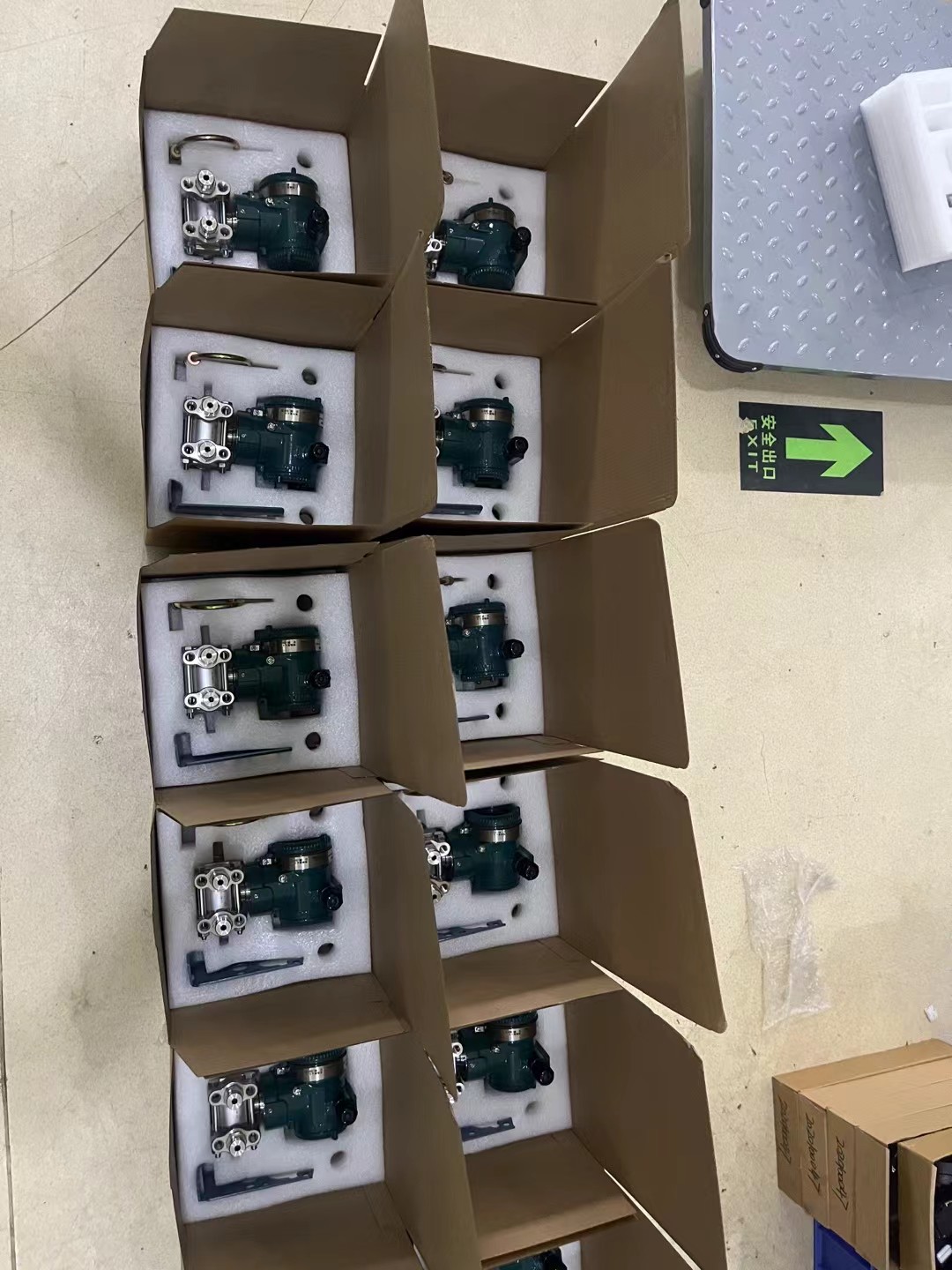

Customized Inner Hole Straightness Tester: Precision Guarantee for Mechanical Processing

In the realm of mechanical processing, precision is paramount. One critical tool that ensures this adherence to precision is the customized inner hole straightness tester. This device is designed specifically to measure the straightness of inner holes, ensuring that they meet the required tolerances and specifications. Whether you are working on automotive parts, aerospace components, or manufacturing precision machinery, understanding how to use and maintain a customized inner hole straightness tester is essential.

Identifying the Need for Precision in Inner Hole Straightness

Precision in mechanical processing is critical in industries like automotive and aerospace, where even small deviations in measurements can lead to significant safety issues. An example of the importance of precision is in the production of engine cylinders. Even a slight deviation in straightness can result in insufficient lubrication and heat dissipation, leading to engine failure. This is where the customized inner hole straightness tester comes into play, ensuring that the inner holes are accurately measured and corrected to meet the required standards.

Understanding the Faults in Inner Hole Straightness

When using a customized inner hole straightness tester, various faults can arise that can affect the accuracy of the measurements. One common issue is the **** (misuse) of the tester. Incorrect alignment or application of force can lead to inaccurate readings and faulty results. For instance, if the tester is not properly aligned with the inner hole, it might not capture the true straightness of the component. Additionally, insufficient lubrication during the testing process can also affect the test results, causing false readings.

Another issue is in the design of the tester itself. A tester that does not have the appropriate range or precision can lead to errors. For example, if the tester cannot accurately measure smaller inner holes, it may provide false negatives indicating that the holes are within tolerance when they are not. This can lead to unsuitable components being integrated into assemblies, which can have catastrophic consequences.

Steps to Effectively Use and Maintain the Tester

To ensure the effective use and maintenance of a customized inner hole straightness tester, several steps should be taken:

Proper Alignment and Force Application

Proper alignment is crucial. Before testing, ensure that the tester is correctly positioned relative to the inner hole. Apply the appropriate force using the tester's mechanism, ensuring it does not deviate from the correct alignment. Incorrect force application can skew the results, making them less reliable.

Regular Calibration

Regular calibration is essential to ensure the accuracy of the tester's measurements. Calibration should be performed using standard calibration tools to verify the tester’s performance. This process helps in identifying any discrepancies and corrects them to maintain precise measurements.

Maintenance

Proper maintenance involves regular cleaning and inspection of the tester. Dust accumulation and wear and tear can degrade the tester's performance over time. Regular inspection helps in identifying any potential issues early, ensuring that the tester remains in optimal condition for accurate measurements.

Practical Tips for Success

Handling with Care

When handling the tester, always treat it with care. Avoid dropping the tester and ensure that it is stored in a dry and clean environment. Using protective cases and covers can also help in maintaining the tester's integrity.

Training and Knowledge

Training is essential for operators to understand how to use the tester correctly. Proper training ensures that operators can perform the tests accurately and consistently. Additionally, keeping up-to-date with the latest testing methods and techniques can help operators stay ahead in their work.

Case Study: A Manufacturer’s Experience

A manufacturer in the automotive industry faced significant quality control issues with inner hole straightness in their engine cylinder production line. The issue was traced back to the misuse and lack of maintenance of the customized inner hole straightness tester. After implementing the recommended steps, including proper calibration, regular maintenance, and training for the operators, the quality improved dramatically. The number of parts failing the straightness test decreased by over 50%, leading to a significant improvement in production efficiency and customer satisfaction.

Conclusion

The importance of customized inner hole straightness testers in mechanical processing cannot be overstated. Ensuring the precision of inner hole measurements is crucial in maintaining the safety and reliability of components in various industries. Through proper use, maintenance, and adherence to best practices, manufacturers can achieve consistent and accurate results, ensuring that their products meet the highest standards of precision.

By following the steps outlined in this article, manufacturers can enhance their quality control processes and reduce the risk of failures due to faulty measurements. Accuracy and precision are the keys to success in mechanical processing, and the customized inner hole straightness tester is a vital tool in achieving these goals.