Is the Multi-Parameter Instrument Displaying Abnormally? First Check the Power Supply, Then Check the Grounding

In the rapidly evolving field of laboratory and industrial testing, multi-parameter instruments have become indispensable tools for monitoring a wide array of parameters such as voltage, current, temperature, and humidity. Despite their reliability, issues like abnormal displays can arise due to various reasons, often requiring systematic troubleshooting to resolve. When you encounter an issue with a multi-parameter instrument displaying abnormally, the first step is to check the power supply. The stability and integrity of the power supply play a crucial role in ensuring that your instrument operates as expected.

Before proceeding with more complex diagnostic steps, it is essential to ensure that the power supply is functioning correctly. The power supply is the backbone of any electronic device; without it, your instrument cannot function. A faulty or unstable power supply can lead to various display issues, including erratic readings, flickering screens, and complete display failure.

Diagnosing Power Supply Issues

To diagnose and address power supply problems, start by checking the voltage at the power inlet of the instrument. Ensure that the voltage matches the specified range on the instrument’s user manual. If the voltage is within the acceptable range, move on to the next step. If not, you may need to investigate external factors such as power fluctuations or line issues.

In addition to the voltage, inspect the power cables and connections for any signs of damage or disconnection. A loose or damaged cable can disrupt the power supply, causing display anomalies. Replacing or repairing damaged cables is a common solution to resolve such issues.

Considering Grounding Issues

After ensuring the power supply is stable, consider the grounding issues. Proper grounding is as critical as a stable power supply for multi-parameter instruments. Grounding serves to stabilize the electrical current and protect against voltage spikes. Without proper grounding, the instrument may display abnormally, and in extreme cases, it could be a safety hazard.

To check the grounding, use a multimeter to test the resistance between the grounding point and the earth. The resistance should be as low as possible, ideally within a few ohms. If the resistance is high, you may need to adjust or re-ground the instrument.

Innovating with a Grounding Strategy

Grounding issues can often be resolved by ensuring the instrument is properly connected to the grounding system. In some cases, a grounding system upgrade may be necessary. For instance, using a ground rod or installing a ground in a location with poor quality ground can significantly improve the overall grounding effectiveness.

Moreover, integrating smart grounding systems can provide real-time monitoring and alerts, helping you proactively detect and respond to grounding issues before they affect the instrument’s performance.

Contrast with Traditional Methods

In contrast to traditional troubleshooting methods, modern diagnostic tools and strategies offer more accurate and efficient solutions. While conventional methods often involve manual checks and tests, smart grounding systems and real-time monitoring offer predictive maintenance and can save time and effort.

For instance, a laboratory technician might traditionally check the power supply and grounding by following a step-by-step checklist. However, a smart grounding system can continuously monitor the grounding resistance and provide alerts if the resistance rises above a certain threshold.

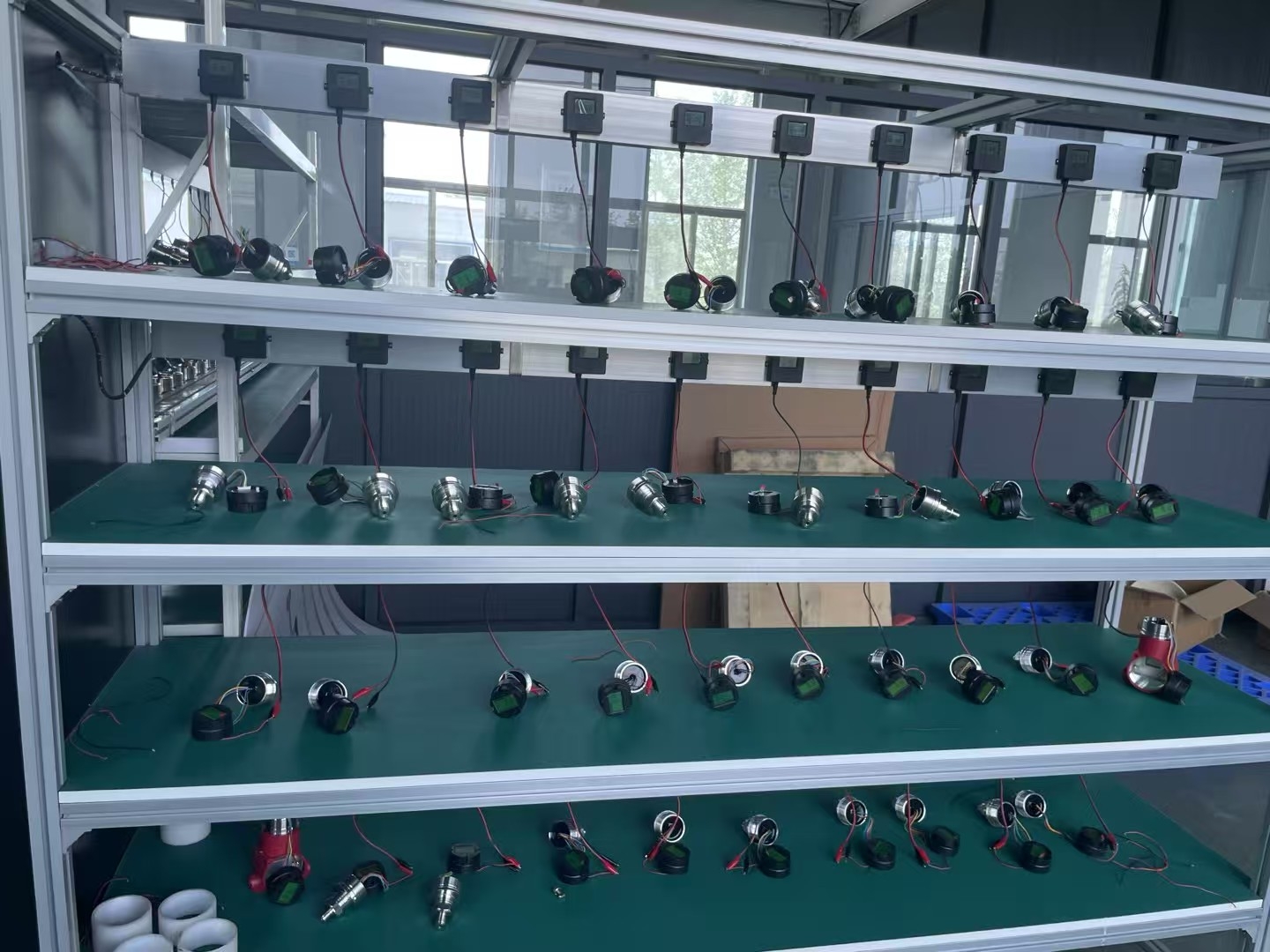

Case Study: A Laboratory’s Multi-Parameter Instrument

A renowned pharmaceutical laboratory experienced frequent display issues with their multi-parameter instrument. Initially, they assumed the instrument was faulty and ordered a replacement. However, upon closer inspection, they realized that the display issues were related to insufficient grounding. By upgrading their grounding system and ensuring all connections were secure, they resolved the display problems and improved the reliability of their testing process.

Conclusion

In conclusion, when troubleshooting a multi-parameter instrument with abnormal display issues, start with the power supply and ground the instrument properly. Both the power supply and grounding are foundational elements that can significantly influence the performance of your instrument. By adopting a systematic and innovative approach, you can avoid common issues and ensure your instrument operates efficiently.