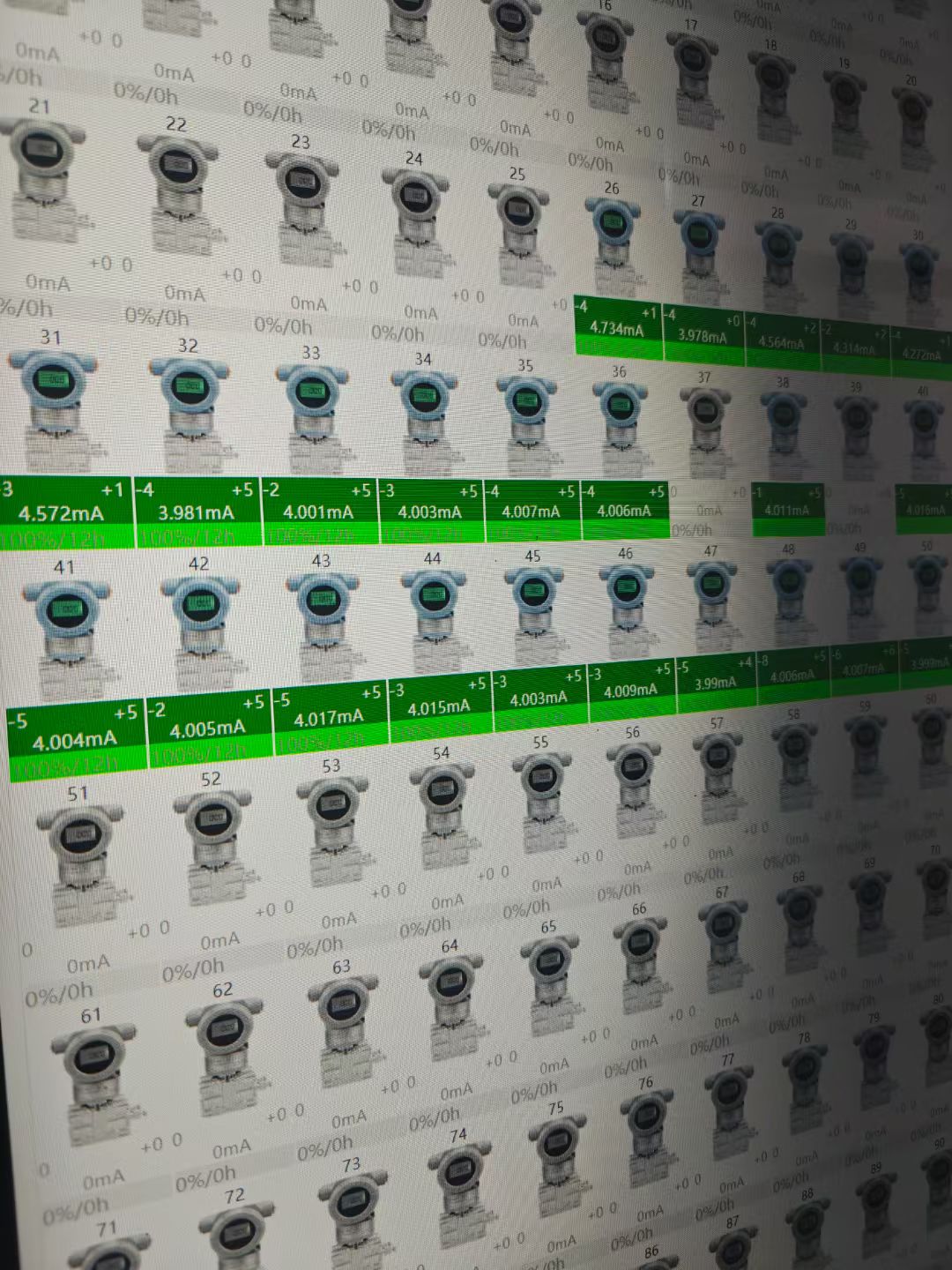

Introductory Overview: Does the Instrument Have No Current Output?

In the realm of laboratory instrumentation and measurement technology, the functionality of an instrument to produce a current output is a critical aspect. When an instrument fails to generate its expected current output, it can indicate a range of issues such as a damaged output tube or a lost calibration value. This problem can significantly impact the reliability and validity of experimental results, making a timely and accurate diagnosis essential for maintaining operational integrity. In this era of advanced handwritten writing techniques, understanding and addressing these issues is paramount for scientific researchers and engineers.

Technical Insights: Resolving No Current Output Issues

When an instrument stops producing the expected current output, troubleshooting begins with an investigation into the possible causes. Output tubes are often the focus of preliminary inspections because they are key components in ensuring the instrument’s output is within specified parameters. Detecting whether the output tube has failed can involve visual inspection with caution, observing signs of damage or wear, and using specialized diagnostic tools to pinpoint the exact issue. Additionally, calibration values are essential for ensuring that the instrument’s output is accurately measured. If these values are lost or corrupted, it could severely compromise the instrument’s functionality and the reliability of its output.

Practical Applications: Real-World Implications

Quality Control in Manufacturing:

In manufacturing settings, instruments that measure electrical current are used to ensure that products adhere to specific quality standards. For instance, in semiconductor manufacturing, current output plays a crucial role in ensuring that integrated circuits function correctly. If an instrument fails to provide a consistent current output, it can lead to subpar product quality, resulting in rework, delays, and ultimately, cost increases.

Safety Monitoring in Industrial Settings:Safety monitoring systems, such as those used in chemical plants, rely on accurate current measurements to detect changes that could indicate hazards. For example, if a leak is detected by a current sensor, it can trigger an immediate response to prevent catastrophic failures. A malfunctioning instrument that cannot provide consistent current output could fail to alert necessary personnel, posing severe safety risks.

Environmental Monitoring:

In environmental monitoring, instruments are used to measure parameters such as pollutant levels, which are often correlated with current outputs. For example, current flow can be indicative of the biodegradation of pollutants in a water body. If the instrument does not produce accurate current measurements, the data can be misleading, leading to incorrect decisions about environmental health and remediation strategies.

Market Dynamics: The Current Status and Trends

The market for laboratory instruments has seen significant advancements in recent years, driven by innovations in sensor technology and data processing capabilities. Companies like Fluke, Keithley, and Yokogawa offer high-precision instruments that can maintain consistent current outputs. These instruments are equipped with built-in diagnostic features that can help identify issues such as output tube damage or calibration value losses. Moreover, the demand for portable and user-friendly instruments is growing, driven by the need for real-time monitoring in various industries.

Future Outlook: Advancements and Innovations

Looking ahead, the future of laboratory instrumentation and current output measurements is promising. Advancements in semiconductor technology are likely to enhance the performance and reliability of current output instruments. For example, the integration of more advanced sensors and microcontrollers could improve the accuracy and consistency of current measurements. Additionally, the rise of artificial intelligence (AI) and machine learning (ML) could further refine the diagnostics of output tube damage and calibration issues, enabling more proactive maintenance.

In conclusion, the functionality of an instrument to provide a consistent current output is crucial for the integrity of experimental results and operational efficiency across various industries. As technology continues to evolve, addressing issues such as output tube damage and calibration value losses will become more efficient, ensuring that instruments continue to deliver accurate and reliable measurements.