Is the Instrument Unable to Reset? Hardware Malfunction or Program Deadlock

Resetting instruments is a routine task in many industries, from manufacturing to research. However, the frustration of an instrument failing to reset can be quite frustrating. This could be due to either a hardware malfunction or a program deadlock, both of which have different implications for troubleshooting and troubleshooting. Understanding the nuances of these two issues is crucial for maintaining the performance and reliability of your equipment.

One, Keyword Analysis

To begin with, let’s dive into the keywords that are central to the issue: "instrument unable to reset." This phrase is often used in forums and troubleshooting guides where people seek answers to recurring problems with their machines. The common factors that contribute to the inability to reset an instrument include hardware issues and software glitches. It is important to distinguish between these two problems, as the solutions can be vastly different.

Two, Problem Analysis

When an instrument fails to reset, it can be a sign of several underlying issues. Let’s break down the most common causes:

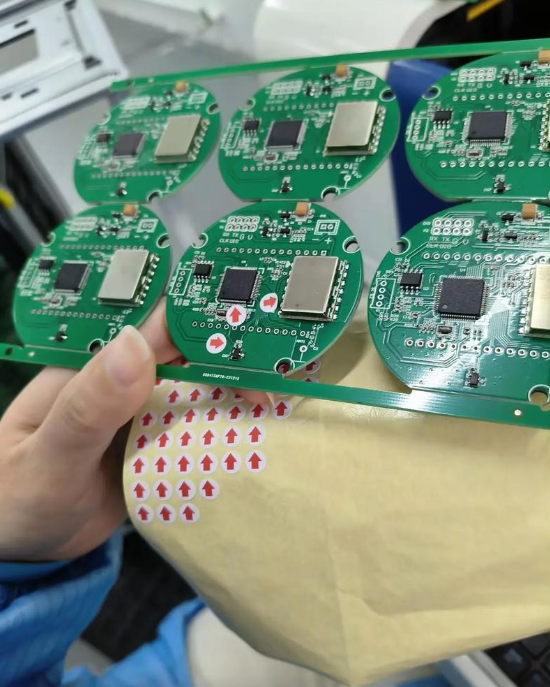

- Hardware Malfunction: This happens when there is a physical problem with the instrument. For example, a broken relay, faulty power supply, or damaged circuitry could prevent the instrument from resetting. To diagnose such issues, one might need to open the instrument and visually inspect the components or perform resistance tests with a multimeter.

- Program Deadlock: This occurs when the software is not functioning correctly, leading to an unintended state that blocks the reset process. Normally, a program deadlock will show no response or an unexpected behavior that can be traced back to errors in coding or configuration.

Three, Impact on Various User Groups

Users from different backgrounds can be affected by this issue:

- Manufacturing Engineers: They rely on instruments for performing repetitive tasks. A malfunctioning instrument can stop production lines, leading to significant downtime and potential revenue loss.

- Research Scientists: They depend on precise instrumentation for their experiments. Even a temporary malfunction can lead to inconsistent data and delayed research progress.

- Service Technicians: They are responsible for maintaining and repairing the instruments. Understanding the difference between hardware and software issues can significantly speed up the repair process and minimize customer complaints.

Four, Solving the Problem

Effectively addressing these issues requires a detailed step-by-step approach:

Initial Diagnosis:

- Check the power supply to ensure that the instrument has power.

- Test the reset function on the instrument itself; sometimes, a simple hardware retest can resolve the issue.

- Ensure there are no external factors, such as electromagnetic interference, affecting the instrument.

Hardware Troubleshooting:

- Open the instrument to inspect the physical components for any visible damage.

- Use a multimeter to check the resistance of critical components, such as relays and fuses.

- Replace any faulty parts and reassemble the instrument.

Software Debugging:

- Review the last software update or change that may have introduced a bug.

- Check the code for common issues such as infinite loops or incorrect handle releases.

- Use debugging tools to trace the program flow and identify the point where the reset process is failing.

Five, Handling Exceptional Situations

In some cases, the issue might be more complex and require advanced techniques:

- Persistent Software Issues: If the software debugging steps do not resolve the issue, consider rolling back to a previous version of the software. Alternatively, perform a factory reset and restore the firmware.

- Complex Hardware Failures: In cases where the physical damage is extensive, it may be necessary to contact the manufacturer for professional repairs or replacement parts.

- Multiple-Device Interference: If multiple instruments are showing similar issues, it could be a batch defect or environmental issue. Ensure that all instruments are calibrated using the same settings and that they are not affected by cross-talk or interference from each other.

Conclusion

In summary, determining whether the instrument unable to reset is due to hardware malfunction or program deadlock is crucial for resolving the issue efficiently. By thoroughly diagnosing and addressing both hardware and software aspects, you can ensure minimal downtime and maintain the reliability of your instruments.

Understanding these distinctions and having a methodical approach to troubleshooting can save a lot of time and resources, ensuring that your operations run smoothly.