Customized Instrument and Meter Design Scheme: A Comprehensive Guide

In the ever-evolving landscape of technology and measurement, the design of customized instruments and meters plays a crucial role in ensuring precise and reliable data collection. This design scheme focuses on creating a robust and tailored solution for various industrial and scientific applications. As we move into 2025, the need for smart, adaptable, and highly accurate instruments becomes more pronounced.

When designing a customized instrument and meter, the primary objective is to align the specifications with the specific requirements of the application. This involves understanding the underlying technologies, selecting appropriate components, and ensuring deployable and maintainable solutions. The following sections outline a dynamic combination architecture that addresses these critical aspects, guiding the readers through the design process from initial concept to implementation.

Architecture Design and Initial Concept

The blueprint for a successful customized instrument and meter design begins with thorough research and understanding of the application domain. This involves consulting architecture design documents and expert opinions to identify key requirements and constraints. The initial concept should aim to streamline the integration of various components that contribute to the overall functionality and performance of the instrument.

At the heart of the design is the need to ensure that the instrument meets the specific needs of the end-users. This includes factors such as data accuracy, environmental tolerance, and user interface design. By prioritizing these aspects, the instrument can be optimized for efficient operation under diverse conditions.

Component Selection

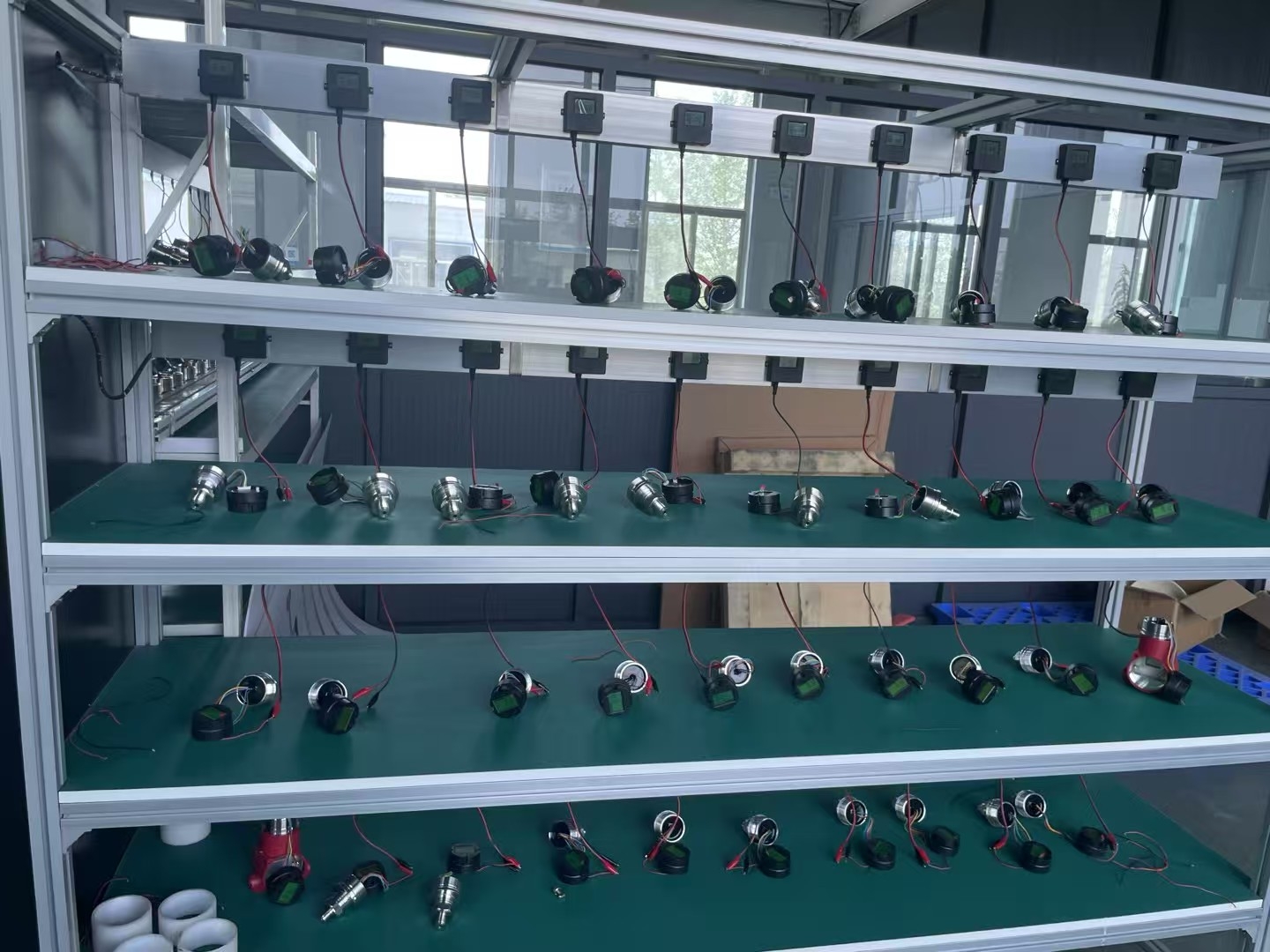

Once the initial concept is set, the next critical step is component selection. In 2025, a wide range of sensors, microcontrollers, and communication modules are available on the market. Each component has its unique advantages and potential drawbacks. Therefore, a balanced approach is necessary to ensure that the chosen components contribute positively to the final design.

Sensors: Sensors are the backbone of any instrumentation system, responsible for capturing raw data. For our design, we selected state-of-the-art sensors that offer high precision and robustness. These sensors are selected based on their accuracy, reliability, and ability to operate in the intended environmental conditions.

Microcontrollers: Microcontrollers manage data processing and communication tasks. We opt for a programmable microcontroller that supports real-time adjustments and can handle complex algorithms efficiently.

Communication Modules: In 2025, wireless communication has become crucial for remote operations. We choose communication modules that support various protocols, ensuring seamless data transmission and network connectivity.

Deployment and Maintenance Strategy

After selecting the components, the focus shifts to the deployment and maintenance strategy. This involves designing the physical hardware, establishing a user-friendly interface, and creating a robust support system.

Hardware Design

The physical design of the instrument must be durable and user-friendly. Ergonomics play a significant role in ensuring comfortable and effective use. Additionally, the design should consider factors such as size, weight, and environmental resistance. In 2025, materials such as stainless steel and tough polymers are favored for their durability and resistance to adverse conditions.

User Interface

A user-friendly interface is essential for operators to understand and interact with the instrument. This includes intuitive display screens, easy-to-navigate menus, and clear instructions. In 2025, touch screens and responsive interfaces have become standard, enhancing user convenience and accuracy.

Maintenance and Support

Maintaining the instrument over its lifecycle is critical for ensuring continued performance and reliability. A comprehensive maintenance plan should include routine check-ups, software updates, and hardware upgrades. In 2025, cloud-based monitoring systems and remote diagnostics make maintenance more efficient and accessible.

Architectural Case Study

To illustrate the practical application of the design scheme, let's consider a case study. The instrument design for a smart water meter project in 2025 involved extensive collaboration between engineering teams and environmental experts. The design process began with an initial concept that prioritized accuracy and environmental resilience.

The chosen components included high-precision humidity and flow rate sensors, a powerful microcontroller, and wireless communication modules. The physical design was crafted to be water-resistant and easy to install. The user interface was designed with a large touch screen and clear, step-by-step instructions.

The deployment phase involved integrating the instrument with a cloud-based monitoring system for real-time data analysis. The maintenance process included regular software updates and remote diagnostics capabilities. This comprehensive approach ensured that the smart water meter met all the necessary requirements and provided reliable data.

Conclusion

The design of customized instruments and meters in 2025 is a multifaceted endeavor that requires a deep understanding of the application domain, rigorous component selection, and a thorough deployment and maintenance strategy. By adhering to this comprehensive guide, engineers can develop robust and tailored solutions that meet the specific needs of various industrial and scientific applications. Ultimately, the goal is to create instruments that are not only accurate and reliable but also user-friendly and maintainable.