Instrument and Meter Installation Steps: The Art of Precision and Craftsmanship

Ensuring accurate and reliable measurement systems is paramount in any industry. This article will delve into the essential steps and methods required for installing instruments and meters. We will go beyond the basics, providing a detailed guide on how to perform these tasks with precision. These steps are crucial for ensuring that your measurement systems operate optimally and provide accurate data.

Installing instruments and meters involves a series of meticulously designed procedures that require both technical expertise and a keen eye for detail. Whether you are setting up a new system or replacing existing equipment, understanding the entire process is key to achieving the desired outcomes. This article will guide you through the essential steps, from selecting the right tools to analyzing the results.

Step 1: Planning and Preparation

Before installing any instrument or meter, it is essential to plan the installation process thoroughly. This begins with understanding the specific requirements of your project. Consider factors such as the type of environment where the instruments will be installed, the measurement parameters to be monitored, and the intended accuracy level.

Decide on the Instruments and Meters Needed

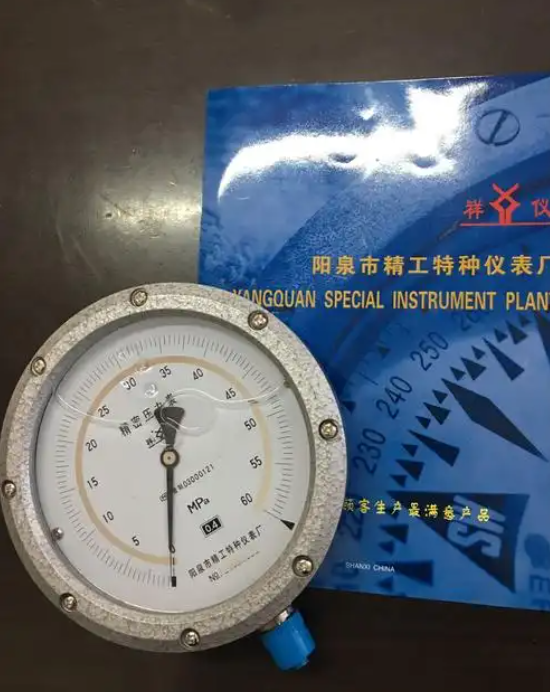

First, identify the exact types of instruments and meters required for your project. For instance, if you are working in a chemical plant, you might need pH meters, flow meters, and temperature sensors. Ensuring the right instruments are selected is crucial for accurate and reliable measurements.

Gather the Required Tools

Next, gather the necessary tools and equipment. This might include calipers, meters, and measuring tapes for precise measurement. Having the correct tools on hand ensures that your installation process is both efficient and accurate.

Step 2: Installation Procedure

Now that you have planned the project and gathered the necessary tools, it is time to proceed with the installation.

Installation Sites and Fixtures

Start by preparing the installation sites. Ensure that the surfaces where the instruments will be mounted are clean and flat. This preparation guarantees a solid foundation for secure installation. Additionally, install appropriate fixtures to ensure the stability and accuracy of the instruments.

Connecting Hoses and Cables

Once the sites are ready, begin connecting hoses and cables. For instruments that require this, such as pressure or flow meters, it is vital to ensure that connections are secure and leak-free. Use appropriate clamps and connectors to maintain integrity and prevent any malfunction during operation.

Mounting the Instruments and Meters

The next step is mounting the instruments and meters. Soak up the experience of aligning the equipment correctly to avoid any misalignments that could affect accuracy. Use mounting brackets or adhere to the specific installation guidelines provided by the manufacturer.

Step 3: Calibration and Testing

After the installation, it is crucial to calibrate the instruments and meters to ensure accurate readings. Calibration involves comparing the instrument reading with a known standard to determine the accuracy.

Calibration Methods

Use the recommended calibration methods for each instrument. For example, some instruments may require traditional mechanical adjustments, while others might need a digital calibration process. Ensure that you follow the manufacturer’s instructions precisely to avoid errors during calibration.

Verification and Data Collection

After calibration, verify the readings by collecting data over time. Compare the readings with known standards or previous values to ensure consistency. Any deviations should be noted and addressed to maintain accuracy.

Step 4: Routine Maintenance

To keep your instruments and meters operational and accurate, it is important to perform regular maintenance checks.

Regular Inspections

Perform routine inspections to check for any signs of wear or damage. This includes checking connections, cables, and mounting brackets for any loose or damaged components.

Cleaning and Lubrication

Cleaning and lubricating instruments and meters can prolong their lifespan and maintain accuracy. Ensure that all moving parts are lubricated, and exterior surfaces are free of dirt and debris.

Conclusion

Installing instruments and meters is a task that demands attention to detail and careful adherence to best practices. By following the steps outlined in this article, you can ensure that your measurement systems are accurate and reliable. Whether you are setting up a new system or replacing existing equipment, these methods provide a solid foundation for precision and craftsmanship.