Instrument Probe Malfunction: A Comprehensive Guide to Problem Resolution

In the intricate and constantly evolving technological environment, instrument probes play a pivotal role in various industries, from manufacturing to environmental monitoring. However, their reliability is not a given and malfunctions can occur, leading to potential risks and downtime. This article focuses on the detection, diagnosis, and resolution of instrument probe malfunctions, providing a comprehensive guide.

Understanding Instrument Probes: Function and Common Issues

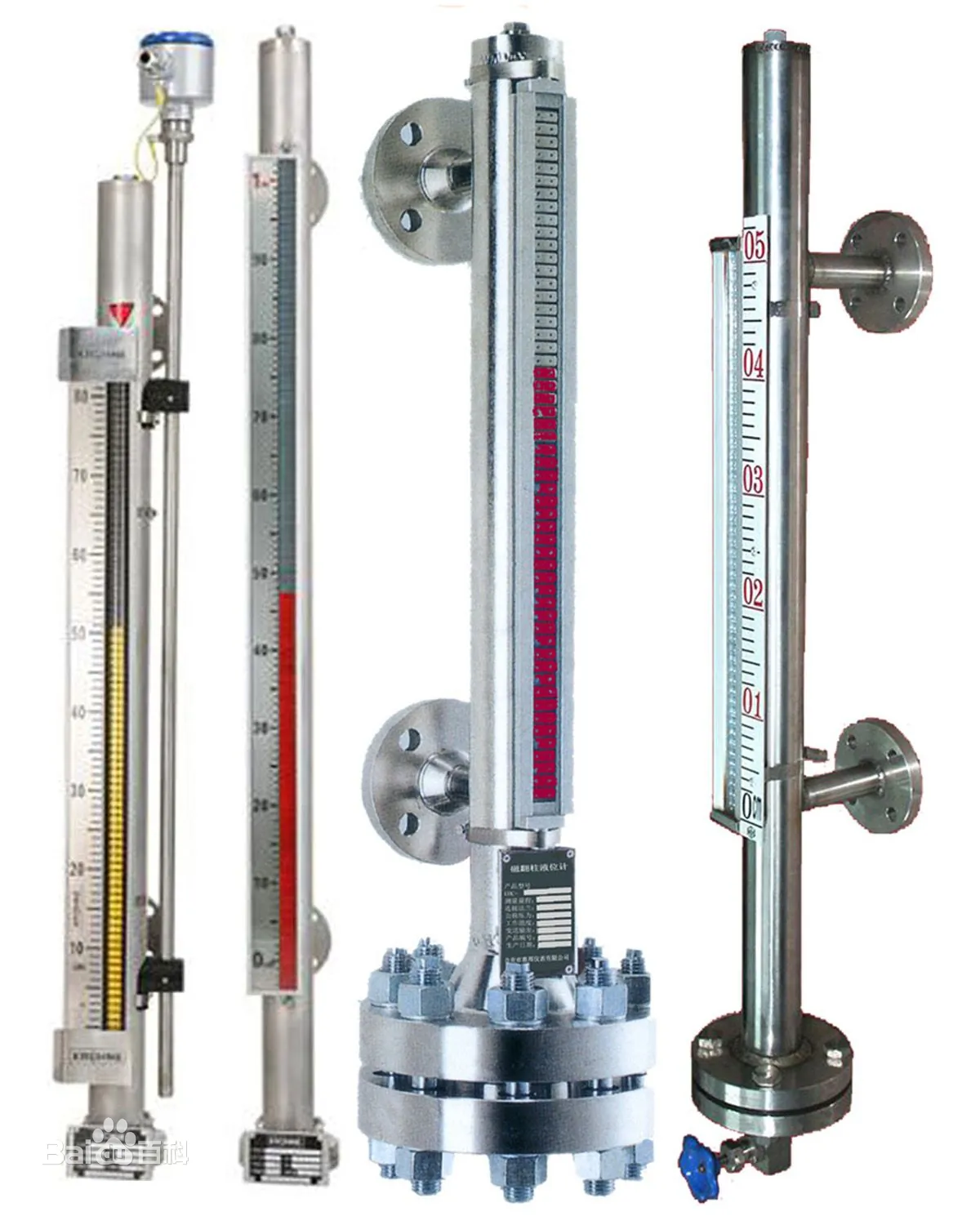

An instrument probe is a specialized sensing device designed to measure and transmit data from a specific location or environment. These probes can detect temperature, humidity, pressure, and many other parameters. In 2025, the proliferation of smart devices and sensors has increased the demand for more accurate and reliable probes. Yet, despite advancements, probes can still face several common issues.

One of the most critical factors in the malfunction of instrument probes is the degradation of the probe’s sensing components over time. For instance, probes that measure temperature may experience calibration drift, where the readings deviate from the expected values. Similarly, probes used in harsh environments may suffer from corrosion or physical damage, leading to performance issues.

Designing a Robust Instrument Probe Malfunction Detection System

Design Architecture and Components

To ensure robust performance and quick resolution, a comprehensive malfunction detection system is essential. This involves designing a robust architecture that can continuously monitor probes and alert operators when an issue arises. In 2025, many experts recommend a hybrid approach that combines real-time monitoring with periodic diagnostics.

Monitoring System:

- Continuous Monitoring: Implement a real-time monitoring system that tracks the performance of each probe. This can be achieved using IoT (Internet of Things) devices that collect and transmit data to a central server.

- Periodic Diagnostics: Schedule periodic deep diagnostics to check the probe’s health, such as calibration checks and physical inspections. This ensures that any underlying issues can be detected and resolved before they escalate.

Alert and Notification System:

- Threshold-Based Alerts: Set up alerts based on predefined thresholds. For example, if the temperature probe shows a reading that is significantly different from expected values, an alert should be triggered.

- Smart Notifications: Use machine learning algorithms to predict potential malfunctions based on historical data. This can help in early intervention and reduce the likelihood of downtime.

Deployment and Configuration

Once the architecture is designed, the next step is to deploy and configure the components. This involves:

- Network Infrastructure: Ensure that the network infrastructure supports both real-time monitoring and periodic diagnostics. This includes reliable internet connectivity and a secure data transfer protocol.

- Software Integration: Integrate the monitoring system with existing IT infrastructure, such as SCADA (Supervisory Control and Data Acquisition) systems, to ensure seamless data flow and alert propagation.

- User Training: Provide training to operators on how to interpret alerts and take corrective actions. This ensures that the system is used effectively and reduces the risk of human error.

Case Studies: Real-World Application of Malfunction Detection Systems

Case Study 1: Environmental Monitoring System

In a 2025 environmental monitoring setup, a network of temperature and humidity probes was installed across a large industrial facility. The monitoring system continuously tracked the performance of each probe and used threshold-based alerts to notify the facility manager of deviations. Whenever a probe showed an abnormal reading, the system notified the manager, who could then schedule a maintenance check.

During a routine check after the alert, it was discovered that a probe had suffered from corrosion due to exposure to a corrosive environments. By addressing this issue promptly, the facility avoided significant disruptions to its operations.

Case Study 2: Industrial Process Control

In an industrial process plant, instrument probes were used to monitor the pressure of fluids in critical pipelines. The malfunction detection system in place continuously monitored these probes and detected a gradual decline in accuracy over several months. Regular diagnostics had not been scheduled, leading to the delayed detection of the issue.

Upon diagnosis, it was found that the probe had suffered from wear and tear due to frequent use. By replacing the probe and rescheduling the diagnostics, the plant avoided potential safety hazards and operational downtime.

Conclusion

Instrument probe malfunctions can have significant impacts on operations and downtime. However, by designing a robust malfunction detection system, deploying it effectively, and maintaining it diligently, organizations can minimize the risks associated with malfunctioning probes. The comprehensive approach outlined in this article can help ensure that probes operate at optimal levels, ensuring reliable data collection and effective operations.