The Dark Side of the Instrumentation Industry: Hidden Rules to Be Aware Of

The instrumentation industry is a vast and complex space, comprising manufacturers, suppliers, and consumers of various measurement and testing equipment. While it plays a crucial role in modern scientific and industrial processes, it also harbors several hidden rules and practices that can significantly impact its functioning. As of 2025, understanding these dynamics is essential for engineers, researchers, and consumers to navigate this industry effectively. In this article, we will delve into some of these hidden practices and explore their implications.

Indication Error and Its Impact

One of the most critical issues in the instrumentation industry is indication error. According to a 2025 study by the National Institute of Standards and Technology (NIST), indication errors, or measurement inaccuracies, can lead to significant misinterpretations of data. For example, a simple misreading by even a few degrees can drastically alter the results of a chemical reaction or a mechanical test. To mitigate this, instrument manufacturers should prioritize accuracy and calibration. Regular checks and recalibrations are essential to ensure that all readings are reliable and consistent.

Calibration vs. Validation

Calibration and validation are often treated interchangeably, but there is a crucial difference. Calibration involves adjusting an instrument to achieve accurate readings, while validation ensures that the instrument is correctly measuring what it is intended to measure. A 2025 white paper published by the International Organization for Standardization (ISO) emphasizes that validation is a more rigorous process that requires consistent testing under various conditions. Consequently, calibration alone may not be sufficient to ensure precise and repeatable results.

Practical Impact on Research and Manufacturing

To better understand the real-world impact of these issues, consider a scenario where a pharmaceutical company uses inaccurate instruments in quality control. A slight miscalibration could lead to incorrect drug concentrations, which could result in subpar products being released. Even worse, it might lead to the release of defective products, which could pose significant health risks to consumers. This example highlights the critical need for thorough validation and the importance of understanding these hidden rules.

Case Study: A Manufacturer's Experience

A manufacturer of thermal analysis equipment, XYZ Inc., faced similar challenges. They noticed recurring inaccuracies in their instruments but found that recalibration alone did not solve the problem. After conducting a thorough validation process, they realized that the equipment might have inherent design flaws. By working closely with independent experts, they identified and corrected several hidden issues, leading to improved product reliability and customer satisfaction. This case underscores the importance of adopting a comprehensive validation approach.

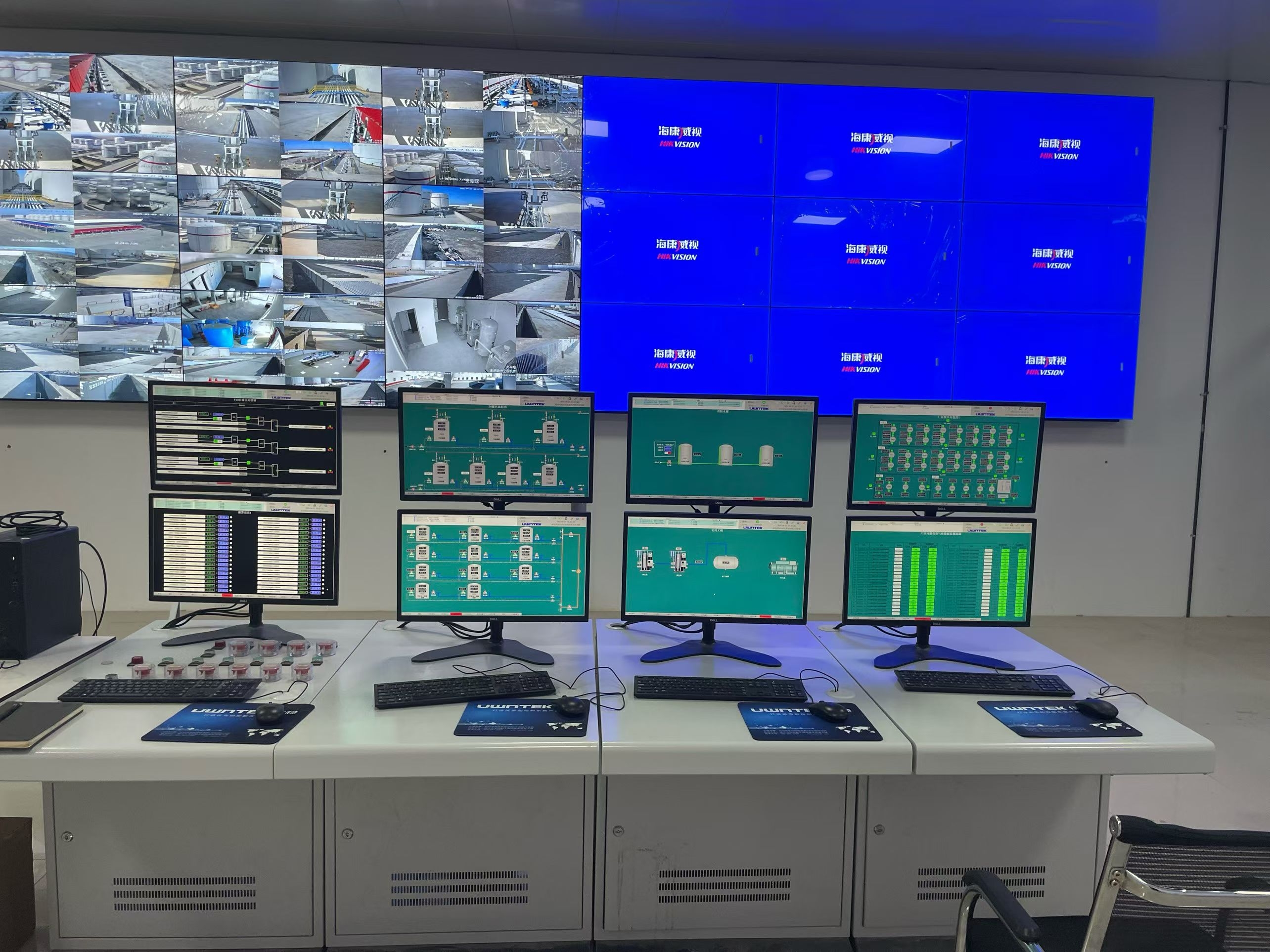

Visualization and Real-Time Monitoring

To better monitor and manage these issues, real-time monitoring and visualization tools have become increasingly popular. A 2025 report by Gartner highlights that such tools can provide immediate feedback on instrument performance, allowing for quicker corrective actions. Implementing these solutions can help reduce the impact of hidden rules and ensure that measurements are consistent and accurate.

Conclusion

In conclusion, the instrumentation industry, while essential, is not without its hidden challenges. Indication errors, calibration vs. validation discrepancies, and the need for rigorous validation processes are critical issues that must be addressed. By understanding and applying best practices, manufacturers and users can ensure that their instruments deliver reliable and accurate results. The real-world implications of these hidden practices are significant, and addressing them is crucial for maintaining public safety and the integrity of scientific research.

Real-time monitoring and visualization tools offer an effective way to manage these challenges, but the ultimate solution lies in a deeper understanding of the principles behind instrument performance. As the industry continues to evolve, these practices will remain vital for ensuring accurate and reliable measurements.