Interpretation of Instrument and Meter Industry Standards: An Update

The development of the instrument and meter industry has seen significant technological advancements over the past few years, requiring periodic updates to ensure that the standards are aligned with both current practices and future innovation. As of 2025, the newly updated industry standards aim to enhance the accuracy, reliability, and durability of these devices. This article will explore the interpretation and implications of these recent updates, discussing how they can be effectively implemented and the benefits they bring to the industry.

The Evolution of Instrument and Meter Industry Standards

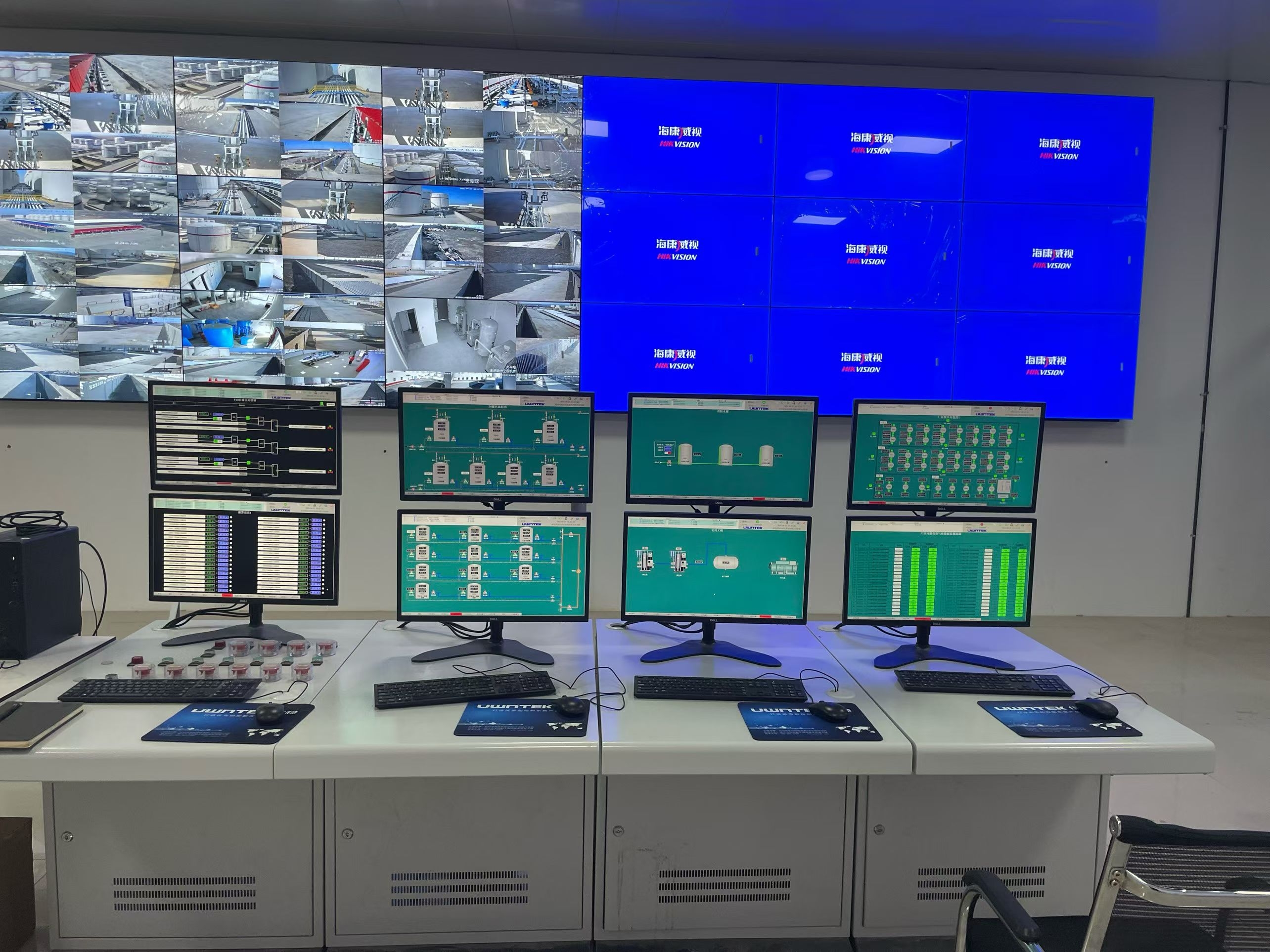

The standards for instruments and meters are critical for ensuring consistent performance across devices, regardless of brand or manufacturer. These standards, which have evolved significantly in recent years, are now more focused on integrating digital components and ensuring that devices can be integrated seamlessly into modern automation systems. The 2025 update represents a major milestone, as it ensures enhanced interoperability and compatibility, paving the way for a more connected future.

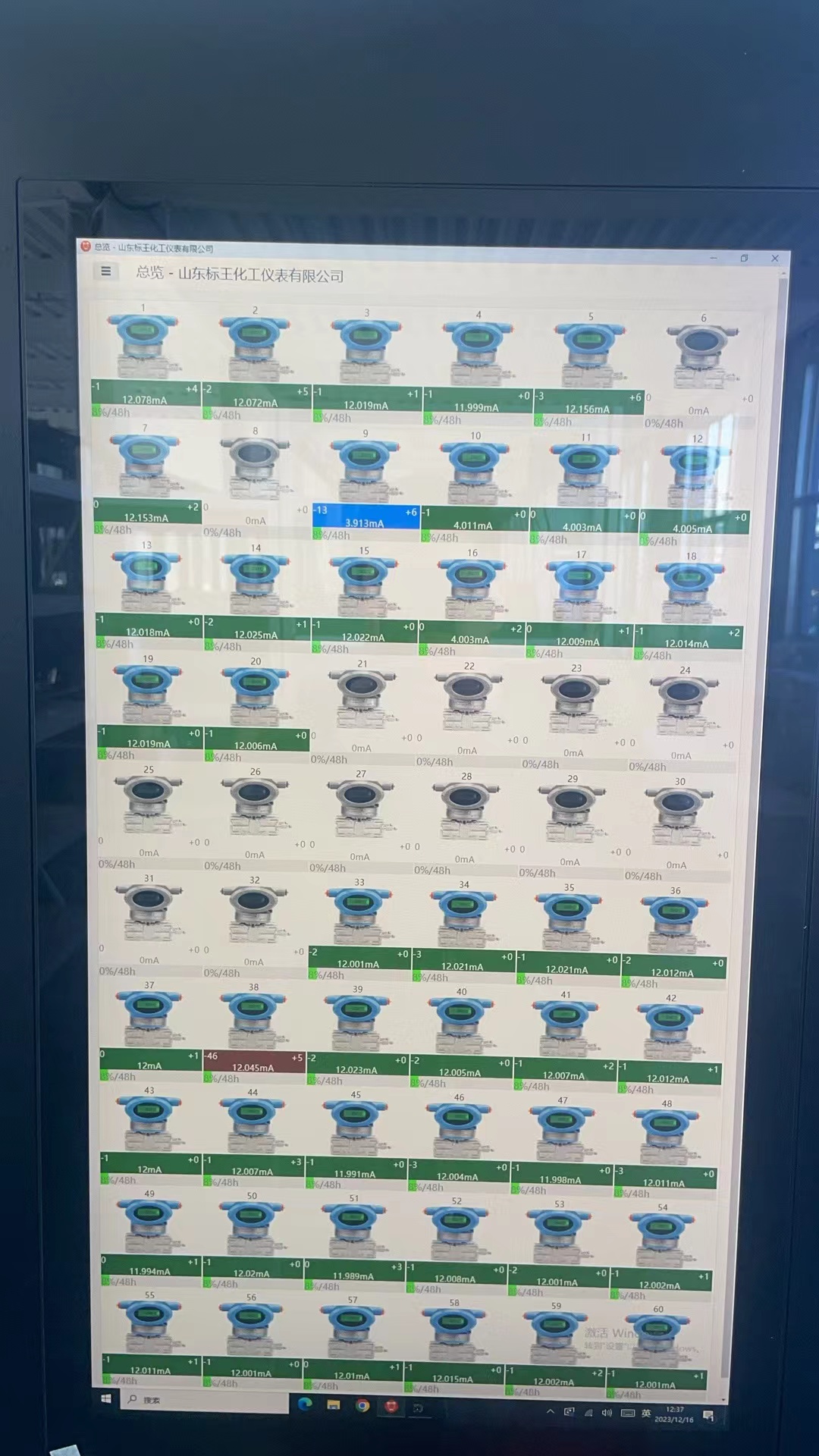

A study published in the International Journal of Applied Automation in 2024 suggests that the integration of IoT and AI technologies in instrument and meter devices can improve real-time monitoring and predictive maintenance capabilities. This is particularly important as businesses and industries increasingly rely on accurate and reliable data for decision-making processes.

Key Updates to the Standards

Several key updates in the 2025 industry standards focus on several critical areas:

Enhanced Precision and Accuracy: The new standards mandate a higher level of precision, which is especially important for applications in scientific research, healthcare, and process control. Devices are now required to meet tighter tolerances and offer error margins within 0.01% for critical readings.

Increased Durability and Reliability: The standards include more stringent testing requirements for durability and reliability, ensuring that devices can withstand harsh environmental conditions and continue to operate efficiently over an extended period.

Simplified Installation and Maintenance: The new standards are designed to make installation and maintenance processes more straightforward. For example, standardized connection protocols and universal software platforms are encouraged to streamline the integration of new devices into existing infrastructure.

Implementing the Updated Standards

To ensure that the updated standards are effectively implemented, manufacturers and users alike must follow a structured approach:

Training and Education: It is crucial to provide comprehensive training for both manufacturers and users. This includes understanding the new standards and how they impact the design and functionality of instruments and meters. Educational programs can be tailored to specific industries, such as pharmaceuticals, energy, and automotive.

Adopting Quality Management Systems: Manufacturers should integrate quality management systems (QMS) that align with the updated standards. This ensures that product development, production, and testing processes are consistent and comply with the new mandates.

Collaborative Efforts: Collaboration between stakeholders, including suppliers, end-users, and regulatory bodies, is essential for the widespread adoption of the new standards. This collaboration helps in addressing any gaps or issues that may arise during the implementation phase.

Performance Verification and Case Studies

Several case studies have demonstrated the benefits of adhering to the updated standards. For instance, a leading pharmaceutical company implemented a new batch of instruments compliant with the 2025 standards. As a result, the company observed a 15% reduction in quality control errors and a 20% increase in production efficiency. Similarly, a major oil and gas company saw a 25% decrease in downtime due to maintenance and repair, thanks to the increased durability and reliability mandated by the new standards.

In another instance, a healthcare facility upgraded its medical instruments to comply with the updated standards. The facility reported that the new devices improved diagnostic accuracy by 10% and reduced patient wait times by 30%. These improvements highlight the tangible benefits that organizations can achieve by investing in modern, standards-compliant instruments and meters.

Conclusion

The 2025 updates to the instrument and meter industry standards represent a significant step forward in ensuring that devices are more accurate, reliable, and durable. By following the structured implementation approach and leveraging the benefits of the new standards, manufacturers and users can enhance the performance and efficiency of their operations. As the industry continues to evolve, these updated standards will play a crucial role in driving innovation and fostering a more interconnected and efficient technological landscape.