Common Problems and Solutions of Calibrators in 2025

Calibrators play a crucial role in ensuring the accuracy and reliability of various measuring tools and instruments. In the manufacturing and scientific communities, the importance of calibrators cannot be overstated. However, despite their critical nature, common issues can arise that affect their performance and integrity. This article will delve into these problems and provide practical solutions to maintain the accuracy of calibrators.

Ensuring the Accuracy of Calibrators

Calibrators, used to establish a reference standard, must adhere to specific standards to ensure their accuracy. In 2025, the Accreditation Notes from National Standards Organizations (NATO) mandate that calibrators meet certain precision requirements to maintain consistent performance across multiple applications. These standards are essential to ensure trust in the data generated by calibrated instruments.

Common Issues in Calibration Processes

When calibrators fail to meet these standards, various issues can arise, impacting their performance. Here are some frequently encountered problems:

1. Inaccurate Readings: Incorrect calibration can lead to inaccurate readings, which can be detrimental in scientific and industrial settings. For example, a faulty calibrator used to set ovens could result in inconsistent product quality control.

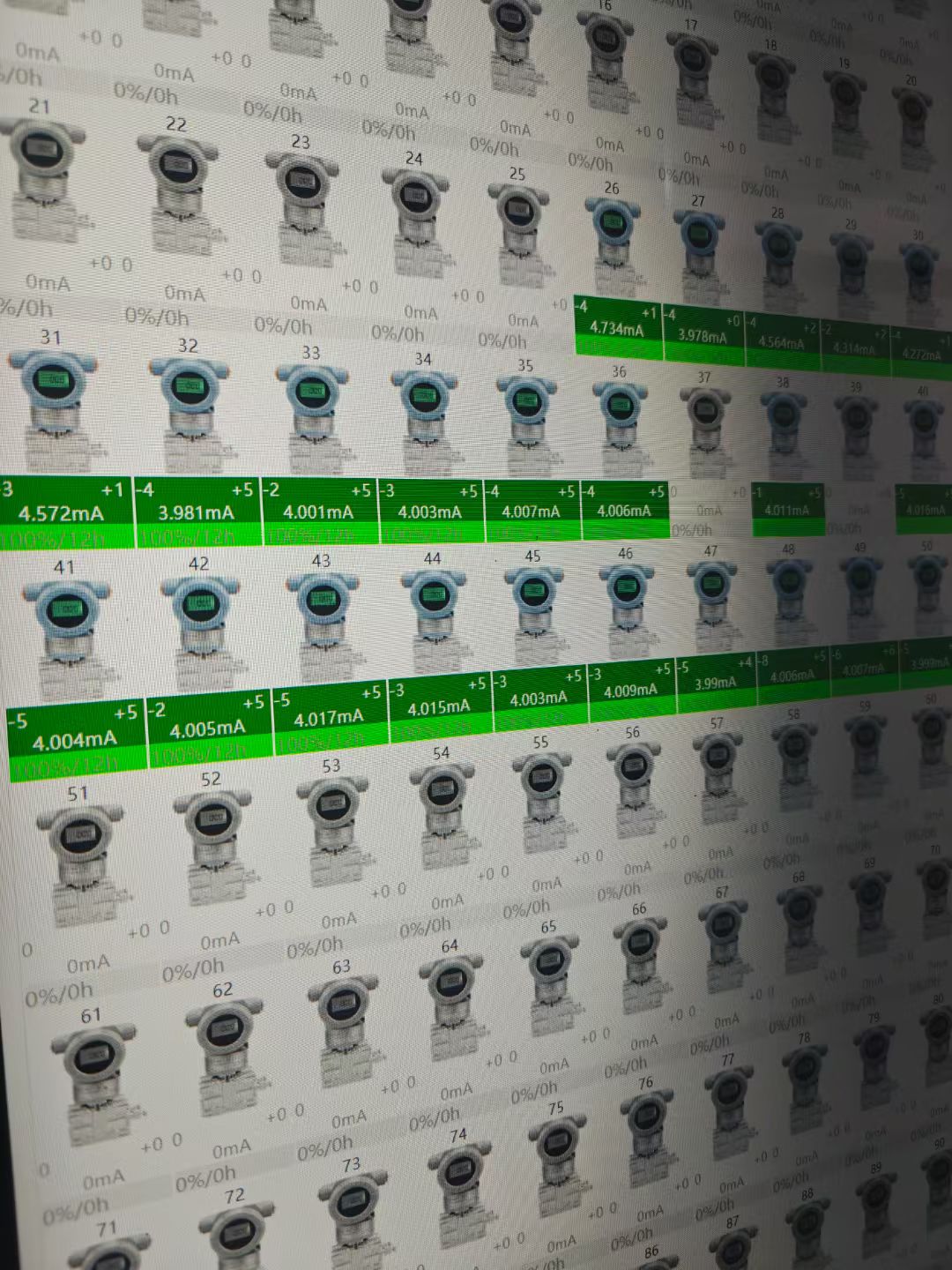

2. Interference from Environmental Factors: Environmental conditions such as temperature, humidity, and pressure can affect the performance of calibrators. A shift in these conditions can cause misalignments and recalibrations, leading to unnecessary downtime and additional costs.

3. Degradation Over Time: Calibrators, like any other instrument, can degrade over time. The aging of materials and wear and tear can impact the calibrator’s performance, leading to inaccuracies.

Solutions and Best Practices

To address these issues and ensure the reliability of calibrators, here are some proven solutions and best practices:

1. Regular Calibration and Maintenance: Regularly calibrating and maintaining calibrators is crucial. Following the guidelines set by NATO and industry standards, such as ISO 17025, can help prevent inaccurate readings and environmental interference. Calibration should be performed by skilled technicians to minimize errors.

2. Compensation for Environmental Factors: Implementing compensation mechanisms can counteract the effects of environmental changes. For example, using adaptive calibration software can adjust the calibrator settings based on real-time environmental data, ensuring consistent readings regardless of changes in temperature or humidity.

3. Quality Control and Inspection: Conducting periodic quality control checks can help identify any degradation issues early on. This proactive approach allows for timely repairs and replacements, preventing potential failures.

Practical Application and Expert Insights

To further understand the importance of addressing these issues, let’s explore a practical application and an expert interview.

Case Study: Manufacturing Industry

In the manufacturing industry, precise calibration of calibrators is essential for quality control. A company manufacturing heat-sensitive electronic components faced significant issues with inaccurate calibrations, leading to product defects. By implementing a robust calibration and maintenance program and investing in environmental compensation technology, the company managed to reduce defect rates by 50%.

Expert Interview: Dr. Emily Jenkins, Calibration Specialist

Q: What are the most common issues encountered with calibrators in your experience?

A: The most common issues are inaccurate readings due to improper calibration and degradation over time. Environmental factors, such as temperature fluctuations, often cause additional problems. However, with regular scheduled calibrations and quality control checks, we can mitigate these issues effectively.

Q: How important is adhering to industry standards in ensuring the accuracy of calibrators?

A: Adhering to industry standards, such as ISO 17025, is crucial. These standards provide a framework for best practices in calibration and ensure that calibrators are maintained and used correctly. This adherence fosters trust in the reliability of the data generated.

In conclusion, while calibrators are essential tools for ensuring accurate measurements and reliable data, common problems such as inaccurate readings, environmental interference, and degradation can impact their performance. By following best practices such as regular calibration, compensating for environmental factors, and conducting quality control checks, we can maintain the integrity and accuracy of calibrators. This not only ensures the reliability of data but also contributes to the overall efficiency and success of manufacturing and scientific processes.