Instrument and Meter Certification Requirements and Process

Instrument and meter certifications are crucial in ensuring the safety and accuracy of devices used across a variety of industries. Ensuring these devices meet specific compliance standards can prevent potential hazards and ensure reliable measurements. The regulatory landscape in this sector is complex, with numerous requirements at both national and international levels. By understanding and meeting these requirements, manufacturers can protect consumers and maintain their reputation. This article will delve into the key certification requirements and the process involved in achieving them, with a focus on ensuring the safety and accuracy of these critical devices.

Understanding the Importance of Certification Requirements

In the realm of instruments and meters, certification requirements serve as a cornerstone for ensuring that products meet critical safety and performance standards. The primary goal is to mitigate potential hazards, such as electrical risks and measurement inaccuracies, that could arise from poorly manufactured or non-compliant devices. As of 2025, regulatory bodies around the world have established stringent guidelines to ensure that these devices adhere to safety standards, thereby protecting end-users and maintaining industry integrity.

For example, the International Electrotechnical Commission (IEC) sets out detailed standards such as IEC 61010, which covers the requirements for safety and environmental testing of electrical equipment. This standard is pivotal in ensuring that all instruments and meters are tested under various conditions to guarantee their reliability and accuracy. Additionally, the National Electrical Manufacturers Association (NEMA) in the U.S. provides additional certification programs that further reinforce the safety and quality of these devices in specific industrial applications.

Identifying Key Compliance Standards

To navigate the regulatory landscape effectively, manufacturers need to familiarize themselves with a range of compliance standards. In 2025, the following key standards are essential for ensuring that instruments and meters meet all necessary requirements:

IEC 61010: Safety Requirements for Electrical Equipment of Measurement, Control, and Laboratory Use

This standard is widely recognized and covers a broad range of safety requirements for electrical equipment. It includes specific safety measures for devices used in measurement, control, and laboratory settings. Manufacturers must thoroughly test their products to ensure they comply with all aspects of this standard.

UL (Underwriters Laboratories) Standards

UL provides a suite of standards for electrical and electronic equipment. For instruments and meters, UL 1838, which focuses on explosion-proof enclosures, and UL 61010, which covers the same as IEC 61010 but is specific to the U.S. market, are particularly relevant. Manufacturers should review and comply with these standards to ensure their devices meet the necessary safety criteria.

NEMA Standards

NEMA provides guidelines specific to the North American market. Standards such as NEMA Standard 30, which covers the protection of electrical equipment from the effects of atmospheric conditions, are essential for ensuring that instruments and meters can withstand various environmental conditions.

Designing a Robust Protection Scheme

Once manufacturers understand the key compliance standards, the next step is to design a protection scheme that ensures devices comply with these standards. This process typically includes several critical steps:

Safety and Reliability Testing

All instruments and meters must undergo rigorous testing to ensure they meet the safety and performance criteria outlined by regulatory bodies. This testing can include:

- Electrical Safety Testing: Ensuring that devices do not pose an electrical hazard to users.

- Environmental Testing: Verifying that devices can withstand various environmental conditions, such as temperature extremes, humidity, and atmospheric pressure.

- Performance Testing: Confirming that the devices provide accurate measurements in various conditions.

Qualitative and Quantitative Analysis

Beyond testing, manufacturers must conduct a qualitative and quantitative analysis to identify potential risks and ensure that all aspects of the device are compliant. This analysis should cover:

- Component Evaluation: Ensuring all components meet the required safety standards.

- Manufacturing Process Review: Verifying that the production process is consistent and adheres to safety protocols.

- User Documentation: Providing clear and comprehensive user manuals and instructions to ensure safe use.

Mitigating Safety Risks

Mitigating safety risks involves implementing safeguards that prevent potential hazards. This can include:

- Reducing Electromagnetic Interference (EMI): Implementing measures to reduce the risk of EMI affecting device performance.

- Improving Design Aesthetics: Enhancing design to reduce the likelihood of accidental contact with live parts.

- User Training: Providing thorough training for users to understand the safe operation of the devices.

Validating and Verifying Device Safety

After designing a robust protection scheme, the final step is to validate and verify the device’s safety and compliance. This involves:

Independent Testing and Verification

Trusted independent testing laboratories should perform comprehensive testing to confirm that the devices meet all necessary safety and performance standards. These laboratories should be accredited to ensure their testing process is credible and reliable.

Compliance Certifications

Obtaining compliance certifications from recognized bodies is essential. Certifications such as UL, IEC, and NEMA ensure that devices meet the necessary safety standards and can be trusted in the marketplace. Manufacturers should apply for these certifications and display the appropriate logos or marks on their products.

Continuous Monitoring and Maintenance

Finally, manufacturers must maintain continuous monitoring and maintain their products to ensure ongoing compliance. This involves regular quality control checks and updating devices to address any emerging safety issues.

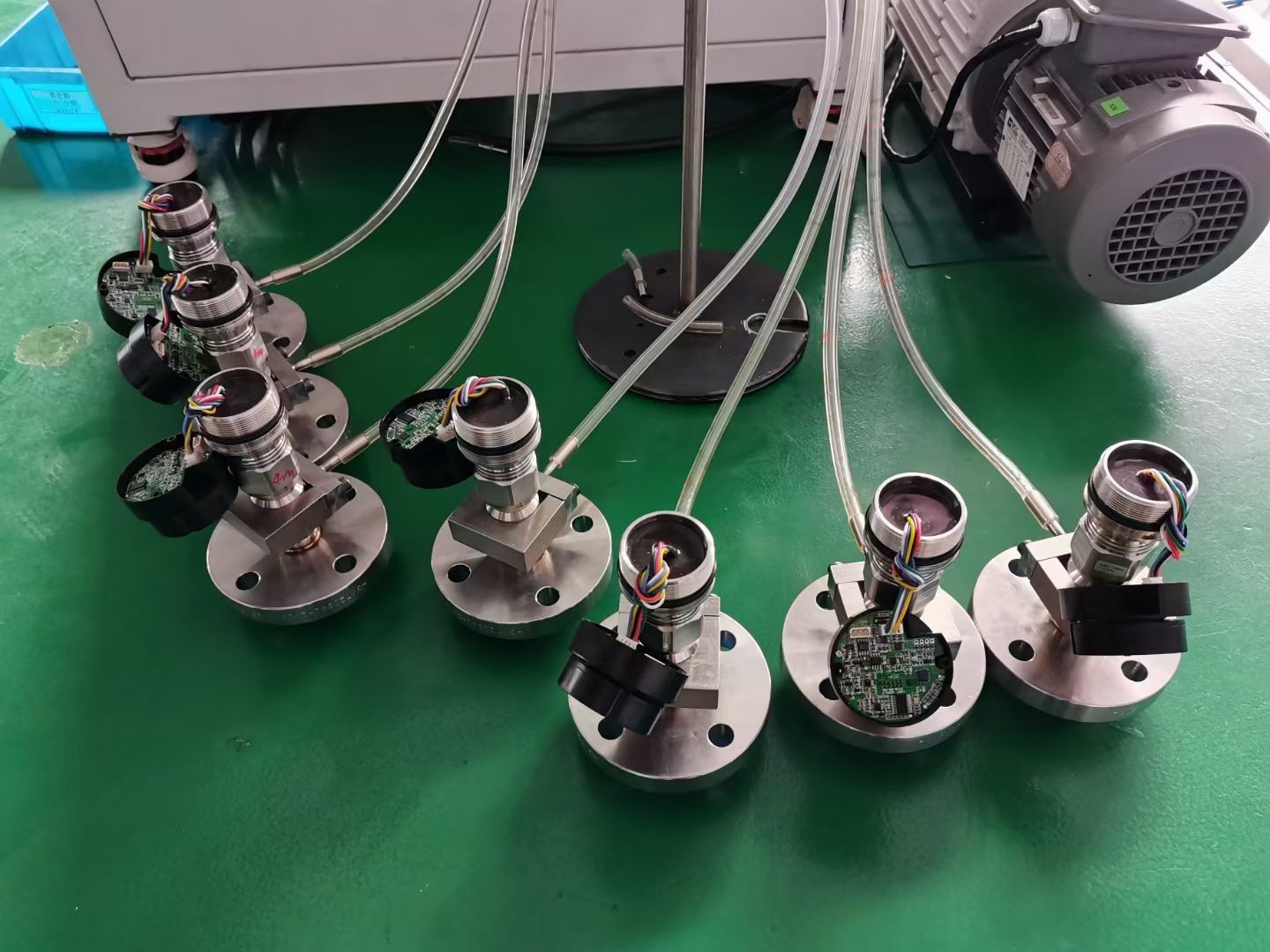

Case Study: Ensuring Safety and Reliability in High-Risk Industries

To illustrate the importance of ensuring compliance, consider a case study involving instruments and meters used in the oil and gas industry. In this high-risk environment, the safety of instruments and meters is paramount to prevent potential accidents and ensure accurate measurements. A manufacturer of these devices developed a comprehensive certification process, including thorough safety and reliability testing, independent verification, and compliance certifications.

The manufacturer worked closely with independent testing laboratories to ensure that their devices met all relevant standards. They also provided extensive user training and documentation to educate users about safe operating practices. As a result, the manufacturer successfully achieved certifications from IEC, UL, and NEMA, demonstrating their commitment to safety and reliability. This effort has led to increased market confidence and a stronger reputation in the industry.

Conclusion

Instrument and meter certification requirements are vital for ensuring the safety and accuracy of devices in various applications. By understanding and adhering to these requirements, manufacturers can prevent potential hazards and maintain industry integrity. The process involves rigorous testing, design of robust protection schemes, independent verification, and continuous monitoring. While the regulatory landscape can be complex, the benefits of compliance are significant, making it a crucial aspect of any manufacturer's product development process.