Evaluating the Long-Term Cost of Using Instruments and Meters

In the realm of technical operations, the choice of instruments and meters is often crucial. The decision to invest in new equipment is not just about the immediate benefits; it's also about long-term costs and maintenance. As of 2025, the total cost of ownership is a key consideration many organizations choose to assess when deciding between various instruments and meters. This involves considering not only the upfront purchase cost but also factors such as operating expenses, maintenance, and downtime.

When evaluating the long-term cost of using instruments and meters, the first step is to understand the different types of costs involved. The initial investment is just the starting point. Operating costs, including energy consumption and replacement parts, must also be factored in. Maintenance and repair costs can vary widely, depending on the reliability and durability of the equipment. Additionally, the cost of downtime during which the failure of an instrument can halt operations is a significant factor.

Training Materials and Course Frameworks

To effectively evaluate the long-term cost of instruments and meters, organizations often rely on comprehensive training materials and structured course frameworks. These resources provide a deep dive into the various types of instruments and their performance characteristics. For instance, a well-designed training course will cover:

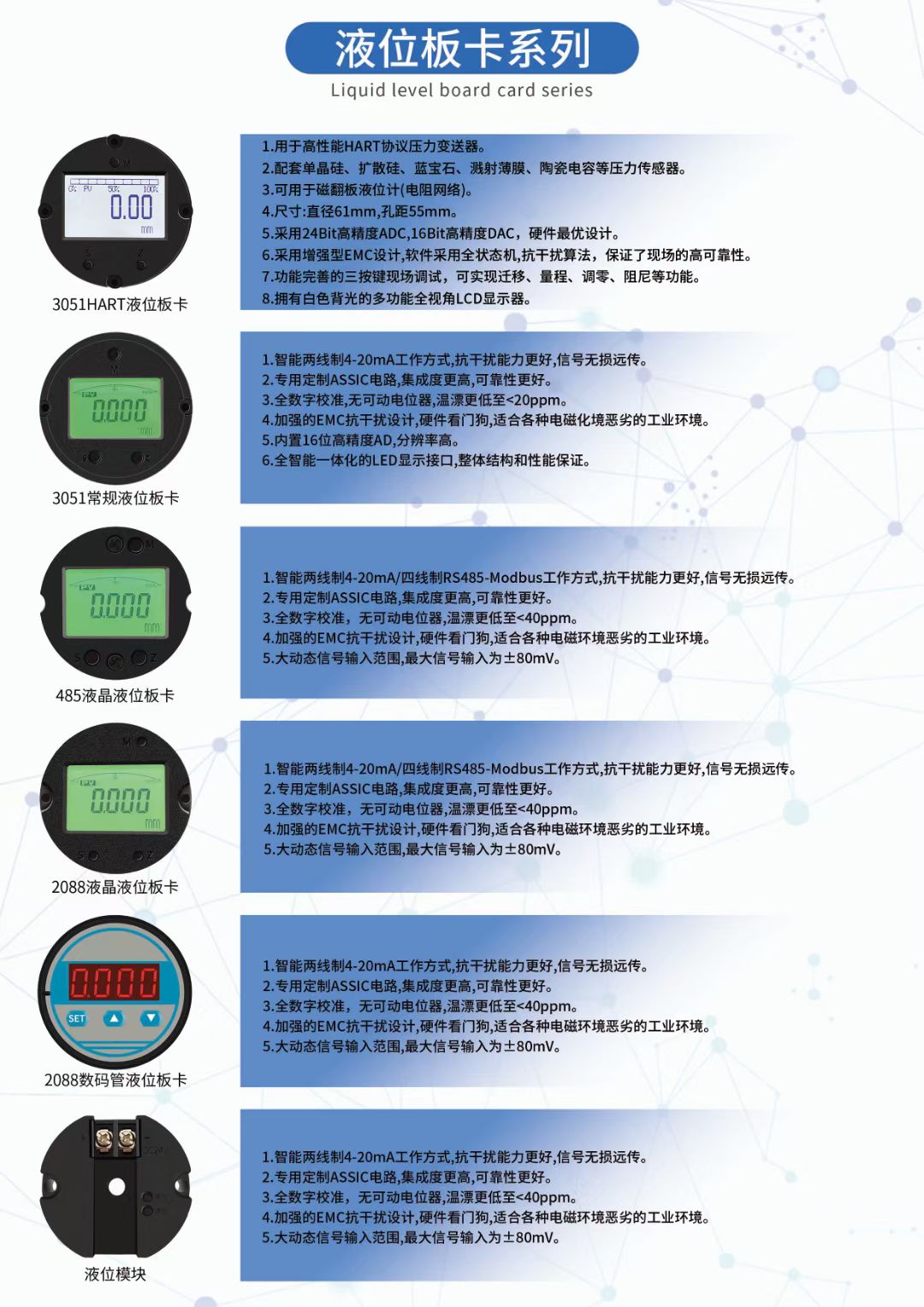

- Types of Instruments and Meters: Course materials from leading manufacturers often include detailed descriptions of different types of instruments and how they are used in various industries.

- Performance Metrics: Training programs often emphasize the importance of performance metrics such as accuracy, precision, and repeatability. Instructors also highlight the need to understand the specific requirements of the operational environment.

- Maintenance and Troubleshooting: Detailed guides on regular maintenance and common troubleshooting techniques are essential to ensure that the instruments remain operational and reliable.

Practical Applications and Training Feedback

The real-world application of these theoretical concepts is what truly makes the training effective. Practical workshops and real-world scenarios provide hands-on experience that helps participants understand the practical implications of their decisions.

One instance involves a company that invests in ultrasonic flow meters. In a training scenario designed by experts, participants learned about the different types of ultrasonic meters and their benefits. They then worked through a workshop where they simulated potential failure points, learning how to identify and mitigate them. After the workshop, participants provided valuable feedback, noting that the practical application helped them see the direct impact of maintenance practices on the longevity and cost-effectiveness of the devices.

Another case involves a factory that switched from traditional mechanical meters to digital instruments. Through a series of training sessions that emphasized the operational savings and reduced maintenance costs of digital meters, the factory was able to justify the initial investment. Feedback from staff highlighted how the training helped them understand the advantages and, crucially, the long-term cost savings.

Conclusion

In 2025, when evaluating the long-term cost of using instruments and meters, it is essential to consider all aspects of cost, from initial purchase to maintenance and downtime. By investing in comprehensive training materials and practical workshops, organizations can make informed decisions that not only meet current needs but also ensure long-term efficiency and cost-effectiveness.