Standardized Process for Instrument Maintenance Management in 2025

The standardized process for instrument maintenance management is crucial in ensuring that industrial equipment operates reliably and efficiently, minimizing downtime and extending the lifespan of critical instrumentation. In 2025, companies are increasingly recognizing the need for robust maintenance practices to support their operations. This article will examine the design, component selection, and deployment considerations for a streamlined maintenance management process, highlighting its importance through real-world case studies and expert insights.

Crafting the Architecture

The first step in designing a standardized maintenance management process is to clearly define the scope and goals of the system. Effective communication among all stakeholders, including maintenance personnel, engineering, and management, is essential. According to industry experts, the architecture must be modular and scalable to accommodate future growth and changes in operational requirements. A common approach is to use a combination of predictive maintenance techniques and condition monitoring systems to ensure that instruments are well-maintained and reliable.

Key Components and Their Selection

Selecting the right components for the maintenance management system is critical. The core components include:

Predictive Maintenance Software: This software uses machine learning algorithms to predict when maintenance is needed, thereby preventing unexpected failures. In 2025, high-level predictive maintenance tools are capable of real-time monitoring and analysis, making them indispensable for modern industrial operations.

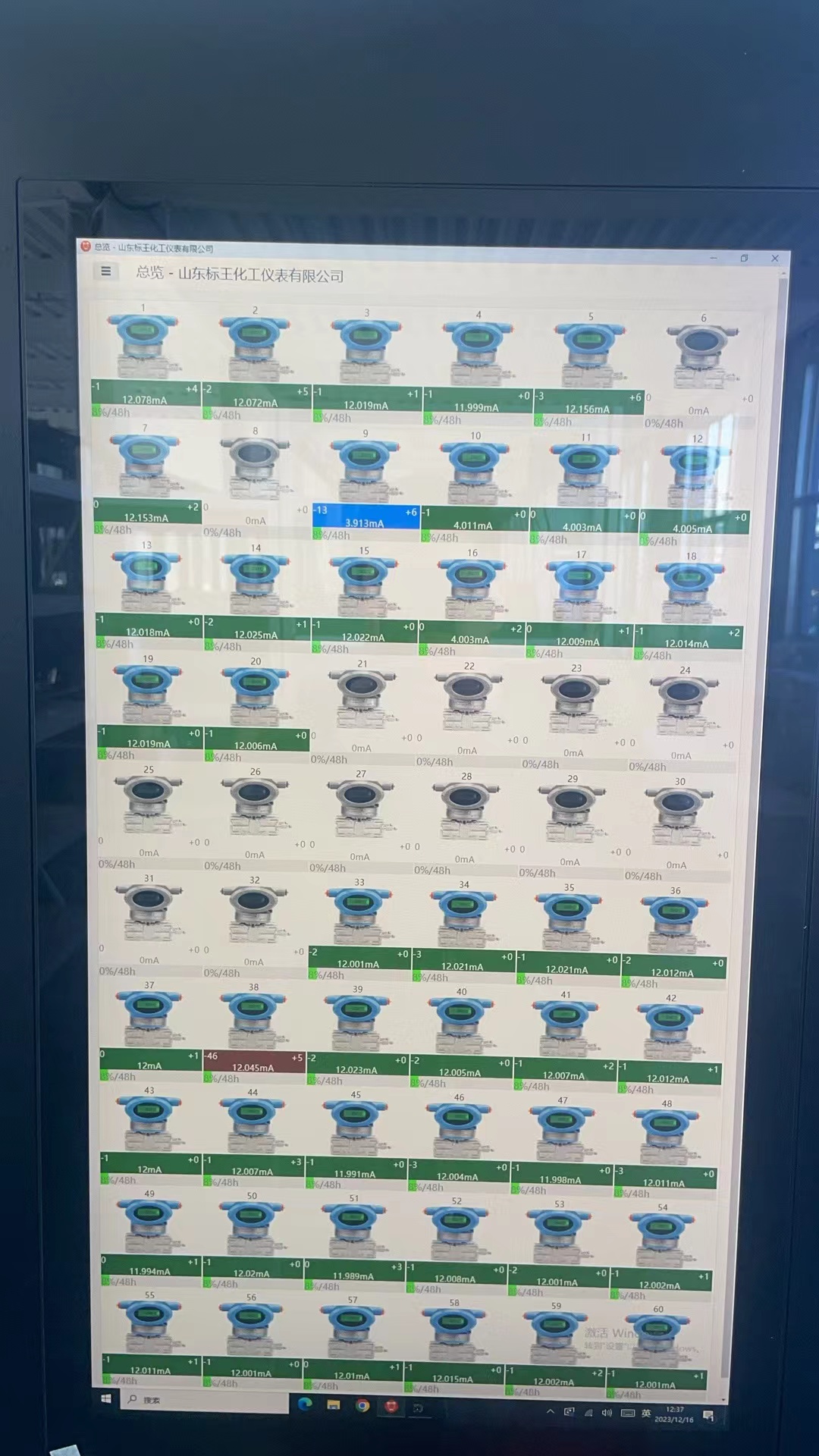

Condition Monitoring Sensors: These sensors continuously measure the performance of instruments and provide real-time data on their health. They are typically placed at key points in the system to ensure that all critical components are monitored.

Maintenance Management Software: This software manages the scheduling and execution of maintenance tasks, tracking asset usage, and ensuring that all maintenance activities are recorded and compliant with industry standards.

When selecting these components, consider factors such as accuracy, reliability, and ease of integration. Additionally, ensuring that the system is user-friendly and accessible to maintenance personnel is key to its success. In 2025, the interface should be intuitive and provide actionable insights, enabling users to make informed decisions quickly.

Deployment and Implementation

Deploying a standardized maintenance management process involves several steps to ensure smooth integration and adoption. The first step is to develop comprehensive guidelines and procedures for maintenance tasks. These guidelines should cover everything from the frequency of checks to the specific actions required during each maintenance session.

Real-World Case Studies

To illustrate the importance of a well-designed maintenance management process, let’s look at a case study from a chemical manufacturing plant. Prior to implementing a standardized system, the plant experienced frequent equipment failures that led to significant downtime and increased operational costs. After adopting a predictive maintenance approach, the plant was able to reduce unscheduled downtime by 30%, indicating the effectiveness of the new system.

Another example comes from a power generation company. By incorporating condition monitoring sensors into their maintenance plans, they were able to preemptively address issues before they resulted in system failures. This proactive approach led to a 20% increase in operational efficiency and a 15% decrease in maintenance costs.

Expert Insights

Expert consensus suggests that a combination of preventive and predictive maintenance strategies is the most effective approach for promoting reliability and reducing costs. According to Dr. Michael Grant, a maintenance engineer at a leading industrial firm, "A well-executed maintenance management process can significantly extend the lifespan of critical equipment and improve overall operational efficiency."

Conclusion

In conclusion, the standardized process for instrument maintenance management is a critical component of any industrial operation. By carefully selecting the right components and deploying a robust maintenance management system, companies can enhance operational efficiency, reduce downtime, and extend the lifespan of their critical instrumentation. Through real-world examples and expert insights, it is evident that a well-designed maintenance management process can provide substantial benefits in terms of cost savings and improved reliability.