Management Specification for Instrument Calibration Plan

What Is a Calibration Plan?

A calibration plan is a detailed document designed to guide the process of calibrating instruments or measurement devices. The primary purpose of a calibration plan is to ensure that the instruments are accurate and reliable, which is crucial in various fields, including manufacturing, research, and quality control. In 2025, there have been numerous instances where inaccurate instruments led to significant errors and costly rework.

Why Is a Calibration Plan Necessary?

A well-defined calibration plan addresses several critical issues. Firstly, it ensures that all instruments are regularly checked and calibrated, maintaining the highest levels of accuracy. Secondly, it identifies potential issues and sets corrective actions to prevent instrument failure. Thirdly, it streamlines the calibration process, making it more efficient and less prone to errors. Finally, a calibration plan helps in achieving compliance with industry and regulatory standards.

Impact on Various Aspects

The impact of an effective calibration plan is broad and far-reaching. From a quality standpoint, accurate measurements guarantee product consistency, leading to higher customer satisfaction and reduced returns. In compliance, stringent calibration procedures ensure that all processes meet regulatory requirements, reducing the risk of legal repercussions. In cost management, regular calibration reduces the risk of product defects and rework, while also preventing costly instrument malfunctions. Furthermore, a well-organized plan improves operational efficiency, as downtime due to instrument failures is minimized.

Core Components of a Calibration Plan

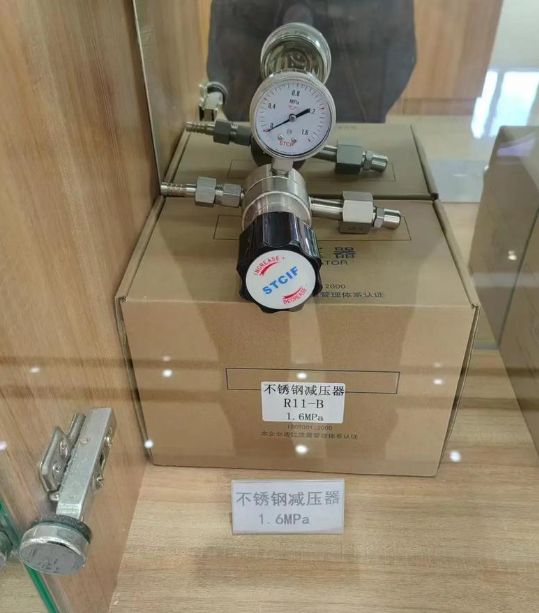

A comprehensive calibration plan consists of several key components. Firstly, it includes the scope and frequency of calibration activities, which are tailored to the specific requirements of the instruments and applications. Secondly, the plan outlines the calibration procedures, including the methods, tools, and personnel involved. Thirdly, it specifies the calibration traceability requirements, ensuring that all measurements are traceable to a national or international standard. Finally, the plan includes monitoring and reporting mechanisms to track performance and adherence to the plan.

Systematic Solutions for Effective Calibration Management

To implement a calibration plan effectively, a systematic approach is essential. Firstly, establish clear roles and responsibilities, ensuring that everyone understands their part in the calibration process. Secondly, choose the right calibration tools and methods, ensuring they are suitable for the specific instruments in use. Thirdly, schedule regular training sessions to keep staff updated on the latest calibration techniques and procedures. Lastly, use digital tools and software to monitor and manage the calibration process, enhancing accuracy and efficiency.

Costs and Risks Involved

Implementing a calibration plan may involve some upfront costs, including the purchase of new calibration equipment, software, and training resources. However, the long-term benefits far outweigh these initial expenses. The primary risk is non-compliance with industry standards, which can lead to significant penalties and reputational damage. Additionally, failing to maintain accurate instruments can result in product defects, delays, and customer dissatisfaction.

An Alternative Plan for Unforeseen Circumstances

While a robust calibration plan is crucial, it’s always wise to have a backup. An alternative plan could be a just-in-time (JIT) calibration approach, where instruments are calibrated only when needed, in response to specific errors or quality issues. This approach is less resource-intensive but requires robust monitoring and a fast response mechanism to address issues quickly.

In conclusion, a well-organized calibration plan is vital for ensuring the accuracy and reliability of measurement instruments. By addressing the core components of such a plan and implementing effective solutions, organizations can significantly enhance their operational efficiency and compliance with industry standards.