Explosion Proof Instrument Customization: Suitable for High-Risk Scenarios Such as the Chemical and Oil and Gas Industries

In the chemical and oil and gas industries, facilities often operate under potentially explosive atmospheres. A single spark or leak can trigger a disaster with severe consequences. Therefore, the use of explosion-proof instruments is critical to ensure safety and prevent accidents. Customizing explosion-proof instruments for these high-risk scenarios is no small feat, and must be tailored to the specific environment and operational requirements. This article aims to guide engineers and designers in understanding how to approach the customization and integration of these essential safety devices.

Designing a Robust Architecture

Designing an effective explosion-proof instrument system requires a thorough understanding of the industry-specific challenges and the relevant standards. The first step is to consult the latest explosion-proof design architecture documentation and guidelines, which provide a comprehensive framework for ensuring safety. Experts also recommend integrating advanced features such as fail-safe mechanisms and real-time monitoring systems to enhance the reliability and robustness of the instrumentation.

Key Considerations

- Environment Assessment: Identify the specific types of hazardous materials and potential energy sources that could cause explosions.

- Conformity to Standards: Ensure all components comply with international standards such as IECEx, ATEX, and UL.

- Customization for Specific Needs: Tailor the design to address unique operational challenges faced by chemical and oil and gas companies.

Selecting the Right Components

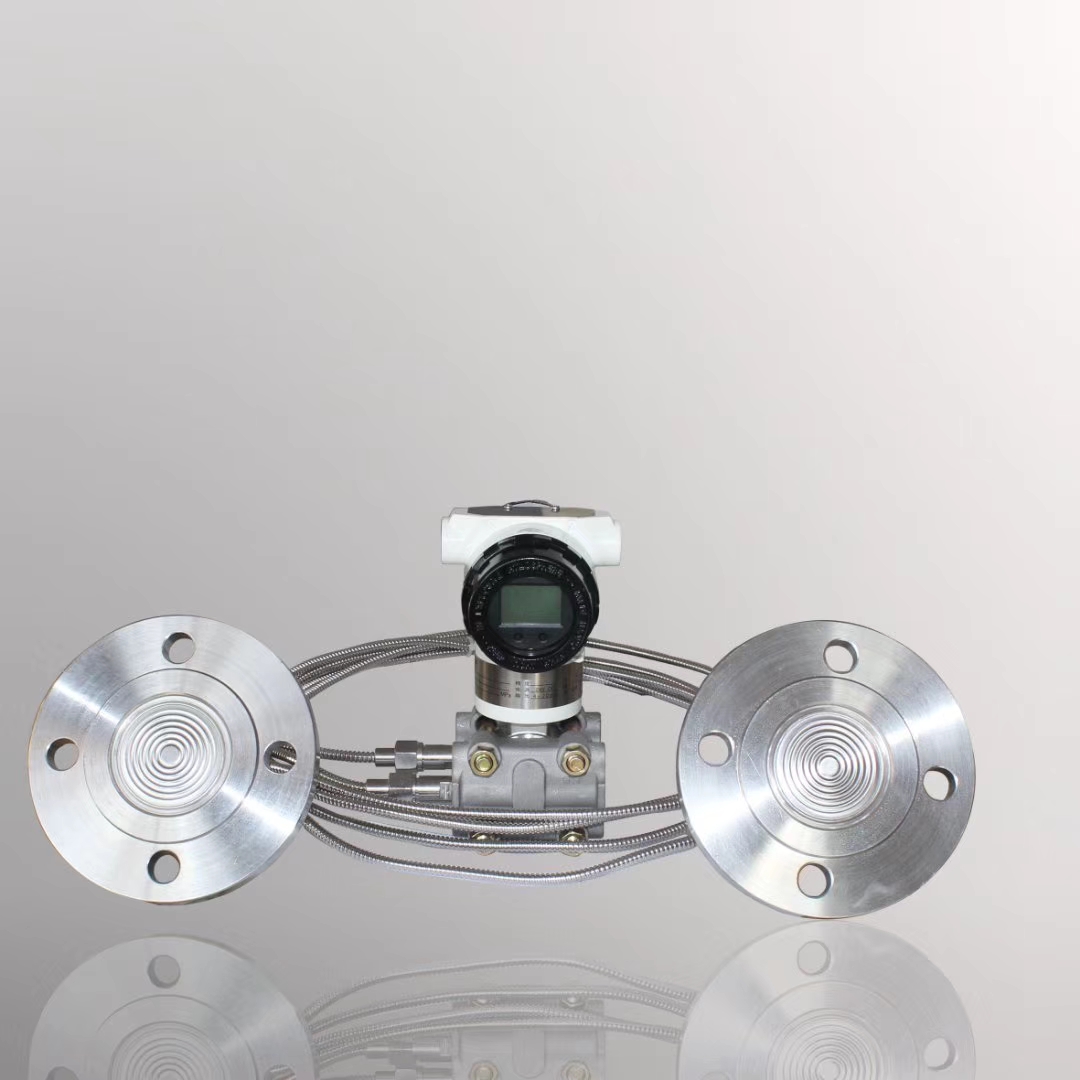

Once the architecture is designed, choosing the appropriate components is crucial. Typically, explosion-proof instruments require specialized sensors, actuators, and communication protocols. Here are some key components to consider:

Sensors

- Explosion-Proof Sensors: These sensors are designed to operate in explosive atmospheres without triggering a hazardous environment. They are often made with materials like stainless steel to withstand harsh conditions.

- Vibration and Temperature Sensors: These sensors monitor critical parameters that can affect the performance and safety of the instruments.

Actuators

- Explosion-Proof Actuators: These ensure that any movement or adjustment made to the instrument is performant and safe under explosive conditions.

- Fail-Safe Mechanisms: Actuators with fail-safe functions can help prevent equipment failures that might lead to explosions.

Communication Protocols

- Modbus, Profibus, and other Industry Standards: Reliable communication protocols are essential for integrating different systems and ensuring data accuracy.

Deployment Strategies

Deploying explosion-proof instruments in a highly controlled and safe manner is critical. The deployment strategy should be carefully planned to minimize the risk of installation errors. Here are some essential steps to follow:

Installation Procedures

- Pre-Installation Planning: Develop a detailed installation plan, including safety precautions and contingency measures.

- Trained Personnel: Ensure that all personnel involved in the installation are adequately trained to follow safety protocols.

- Step-by-Step Checklist: Create a checklist that covers all necessary procedures for a successful installation.

Operation and Maintenance

- Routine Inspections: Regularly inspect the instruments to ensure they are functioning correctly and are not exposed to factors that could damage them.

- Logbook Management: Maintain detailed logs of inspections, maintenance activities, and any deviations from standard operating procedures.

Case Study: The Smith Chemical Plant

Smith Chemical Plant integrated customized explosion-proof instruments into their facility to manage highly flammable substances. By following a systematic approach, including thorough design, component selection, and deployment strategies, they successfully reduced the risk of explosions. The plant now operates with enhanced safety standards, making it a leading example in the industry.

Conclusion

Explosion-proof instrument customization is a vital component in ensuring the safety and reliability of high-risk environments in the chemical and oil and gas industries. By carefully designing the architecture, selecting the right components, and implementing robust deployment strategies, facilities can minimize the risk of accidents and ensure continuous operation. Understanding the nuances of each step is key to achieving a successful and safe integration of these critical safety devices.