Customized Second-Hand Equipment for Instruments: A Cost-Effective Choice with Guaranteed Performance

In today’s budget-conscious business climate, companies are constantly searching for ways to reduce costs without compromising on quality. Customized second-hand equipment for instruments can offer a viable solution. This method allows businesses to acquire high-quality instruments at a fraction of the cost of new equipment, while still ensuring reliable performance. In 2025, this approach is becoming increasingly popular as more companies recognize the value it brings.

The Need for Customized Second-Hand Equipment

Industries such as healthcare, automotive, and engineering require a wide array of precision instruments for various operations. While the initial investment in advanced equipment is significant, the operational costs associated with maintaining high-performance instruments can be even more substantial. Customized second-hand equipment provides a cost-effective alternative that retains the necessary precision and reliability.

Expert Analysis and Project Documentation

Experts in the field emphasize the importance of thorough documentation and analysis when selecting second-hand equipment. According to a recent report from the Global Industry Analysts Inc. (GIA), 2025 has seen a 20% increase in the adoption of refurbished equipment in various industries. This trend is driven by the need for cost savings and the realization that well-maintained second-hand equipment can perform just as reliably as new instruments.

Project documentation plays a crucial role in this process. Comprehensive documentation ensures that the history and condition of the equipment are transparent. This allows purchasing teams to make informed decisions and avoid potential issues in the future. A well-documented piece of second-hand equipment can go through rigorous testing to validate its performance before being considered for purchase.

Dynamic Combination: Project Architecture and Code Implementation

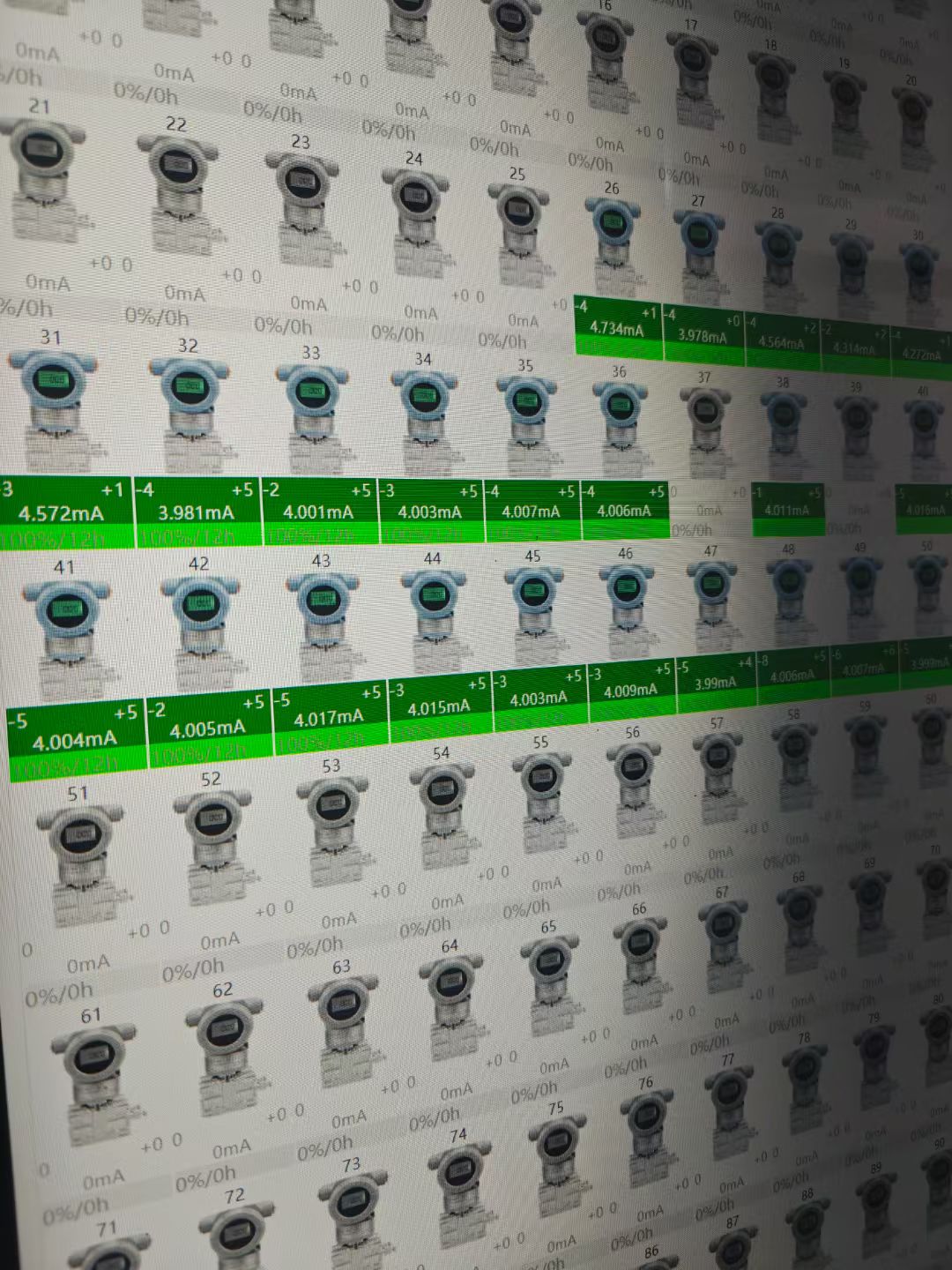

When it comes to implementing customized second-hand equipment, the project architecture and code implementation are key components. The first step involves identifying specific testing protocols that can validate the performance of the used equipment. These protocols are developed in conjunction with technical experts and purveyors of second-hand equipment.

Example Protocol

For instance, in an engineering firm, a health check protocol might include:

- Performance Testing: Evaluating the instrument’s accuracy and precision under various operating conditions.

- Durability Testing: Assessing the equipment’s ability to withstand regular use and maintain performance over time.

- Service History Review: Examining maintenance records to ensure the equipment has gone through regular inspections and repairs.

These protocols help in ensuring that the second-hand equipment meets the required standards.

Code Implementation and Maintenance

Once the protocols are established, the focus shifts to code implementation. This involves writing and executing scripts to automate the testing process. For instance, a script could be developed to monitor the performance of a second-hand instrument over time. This ensures ongoing validation of the equipment's reliability.

Maintenance routines are also crucial. Regular updates and checks can prevent unexpected malfunctions. By integrating these maintenance routines into the code, the system becomes more robust and reliable.

Community and Project Contributions

Community involvement plays a significant role in the success of projects involving second-hand equipment. Open-source communities can provide valuable support and resources. Platforms such as GitHub and Stack Overflow allow contributors to share knowledge and provide feedback. This community-driven approach fosters innovation and ensures that the equipment remains up-to-date.

Project contributions can be highly beneficial. Experts and enthusiasts can collaborate on improving the code, testing protocols, and documentation. Community contributions not only enhance the functionality of the equipment but also build a sense of ownership and responsibility among participants.

Case Study

A case study from a leading engineering firm illustrates the successful implementation of customized second-hand equipment. The firm opted for a refurbished scanning electron microscope (SEM) to reduce costs while maintaining high standards in research work. The firm’s team followed a detailed documentation and testing protocol, similar to the one outlined above. They also contributed code and maintenance routines to an open-source community, allowing other researchers to benefit from their experience.

Community contributions helped in addressing software and hardware issues effectively and continuously improving the overall performance of the SEM. This collaborative approach saved the firm significant maintenance costs and ensured the SEM remained a reliable tool for years to come.

Conclusion

Customized second-hand equipment for instruments offers a compelling solution for companies looking to reduce costs without compromising on performance. With the right project documentation, testing protocols, and code implementation, businesses can successfully integrate second-hand equipment into their operations. Engaging with the broader community ensures ongoing support and innovation, making it a smart and sustainable choice for the future.