Internal Structure and Principle of Instruments and Meters

In 2025, instruments and meters have become indispensable tools in various industries, from manufacturing and infrastructure to healthcare and research. These devices play a pivotal role in measuring, analyzing, and standardizing processes. Yet, understanding their inner workings and the principles behind them can be quite daunting. This article aims to demystify the internal structure and principles of instruments and meters, providing insights into how these tools work and how they can be effectively utilized.

One, What Is the Essence of Internal Structure and Principles of Instruments and Meters?

At its core, an instrument or meter is a device designed to measure physical or chemical properties such as voltage, temperature, pressure, and flow rate. In 2025, these devices have evolved to be highly accurate, reliable, and compact. The internal structure typically consists of a sensor, a measuring unit, and a display (or interface). The sensor detects the physical property, the measuring unit processes the data, and the display or interface provides a readable output.

Two, Why Do These Instruments and Meters Exist?

Instruments and meters are essential for ensuring precision in measurements and maintaining quality control. Their existence addresses the need for standardization in various sectors. The adeptness of instruments and meters allows for consistent and accurate data collection, which is critical for ensuring safety, compliance, and efficiency.

Three, The Impact on Various Sectors

In 2025, the impact of instruments and meters spans across multiple industries. In the manufacturing sector, they ensure product quality and production efficiency. In healthcare, they monitor vital signs and treatments. In research, they facilitate precise data collection and analysis. Thus, the use of these instruments and meters directly influences the accuracy and reliability of data, operational efficiency, and ultimately, the overall performance of each industry.

Four, Core Modules

The internal structure of instruments and meters comprises several key components. Primarily, the sensor is the component responsible for detecting the physical property of interest. There are multiple types of sensors, such as thermocouples for temperature and pressure transducers for pressure.

The measuring unit processes the data collected by the sensor. This unit often includes a microcontroller, converters (such as analog-to-digital converters), and other electronic components that ensure the data’s accuracy and precision.

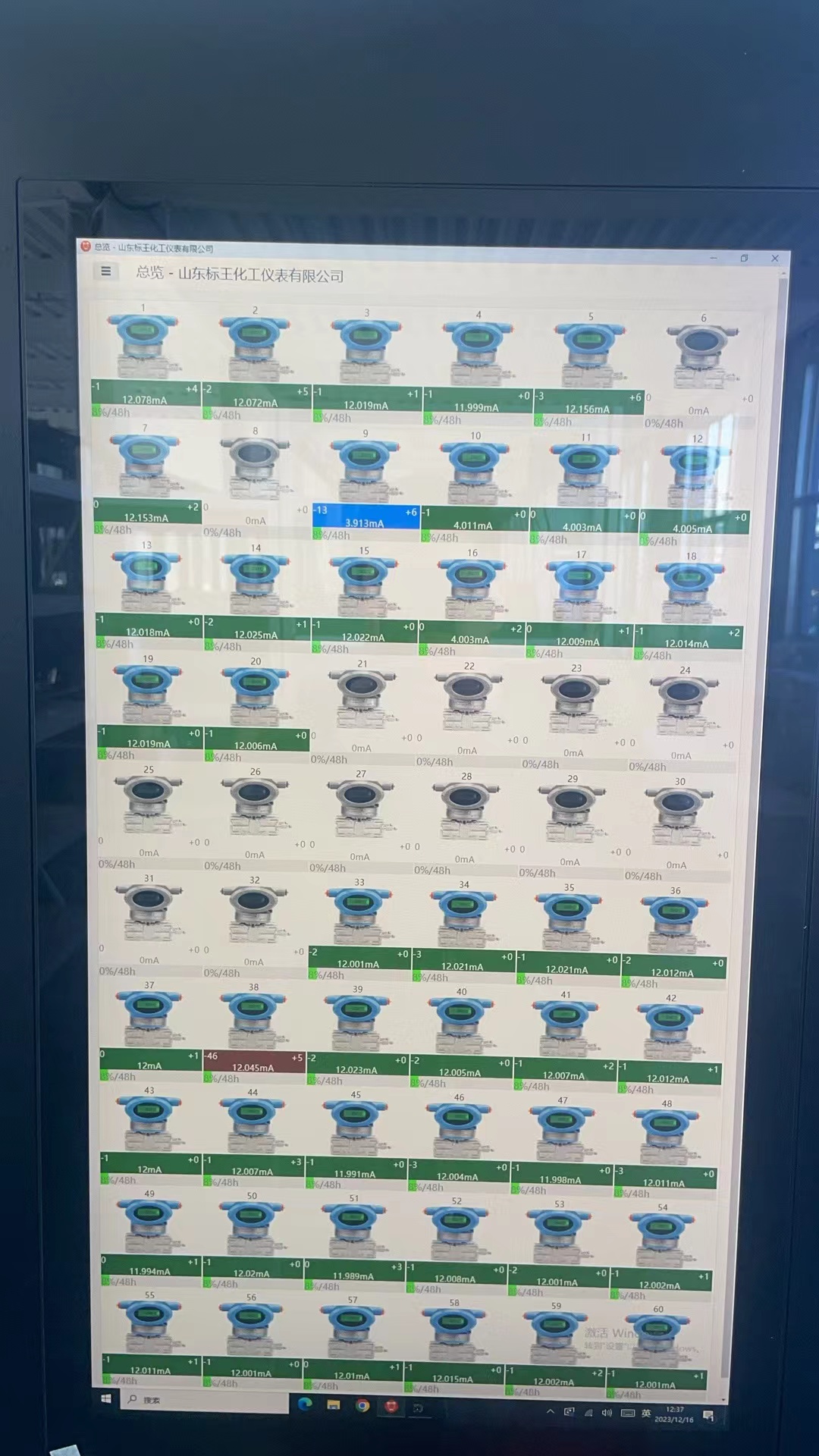

Finally, the display or interface presents the measured data in a readable format, whether it be a digital screen, a chart, or a network connection for remote monitoring.

Five, Systematic Solutions

The design and manufacturing of instruments and meters involve a systematic approach to ensure optimal performance. First, sensor selection is critical. High-quality sensors are vital for accurate data collection. Secondly, measuring units need to be robust and reliable. A well-designed microcontroller and data processing system ensure consistent and accurate data. Lastly, user interface design should be intuitive, providing easily interpretable readings and controls.

Six, Costs and Risks

Crafting high-quality instruments and meters involves significant costs, including the development of sensors, the design of measuring units, and the cost of skilled labor. Additionally, the risk of failure can be high, particularly if the design is flawed or if the instruments are not calibrated regularly. These risks can lead to inaccurate measurements, which can have significant consequences in industries reliant on precise data.

Seven, Alternative Plans

In the event that the primary instruments and meters fail or need maintenance, there are backup solutions available. These include portable alternatives or sub-systems that can quickly step in, ensuring continuous operations. Additionally, cloud-based monitoring systems can provide real-time data and diagnostics, allowing for swift troubleshooting.

Conclusion

In conclusion, instruments and meters are crucial tools, underpinned by complex yet intricate designs. Understanding their internal structure and principles not only aids in the effective use of these devices but also contributes to the overall efficiency and reliability of various industries. By optimizing sensor selection, measuring units, and user interfaces, and by employing robust backup plans, the benefits of instruments and meters can be maximized, ensuring precise and accurate measurements in a multitude of applications.