The 2025 Measurement Instrument Equipment Exhibition: A Showcase of Cutting-Edge Precision

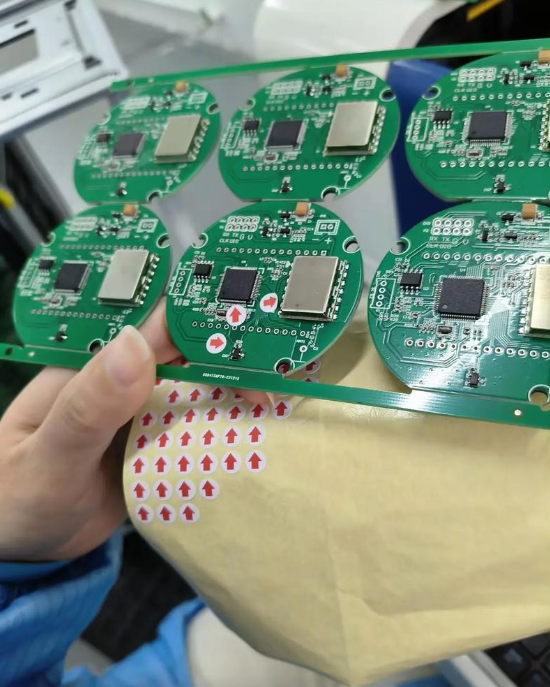

The 2025 Measurement Instrument Equipment Exhibition, launched recently in Hengyang, is a hub for showcasing advanced and precise measurement technologies. This event, attracting nearly a thousand cutting-edge instruments, sheds light on the latest advancements in the field. High-precision instruments play a critical role in various industries, from aerospace and automotive to healthcare and environmental monitoring. The exhibition offers a platform for manufacturers, researchers, and industry professionals to explore and innovate.

This exhibition, with a strong emphasis on innovation and precision, highlights the importance of high-precision instruments in ensuring accuracy and reliability in modern manufacturing processes. The array of instruments, from laser interferometers to atomic force microscopes, underscores the continuous push for technological improvement and precision in various applications.

Addressing the Challenges: Precision Measurement Problems Requiring Innovative Solutions

Precision measurement instruments are essential for achieving accurate and reliable results in a wide array of applications. However, they also pose several challenges. One significant issue is the calibration of instruments, which requires rigorous standards and advanced techniques. Calibration errors can lead to inaccuracies that can have severe consequences, particularly in industries such as aerospace and healthcare. Another challenge is the interoperability of these instruments, especially in complex systems where multiple instruments need to work together seamlessly.

Experts in the field have identified several factors contributing to these measurement challenges. Instability in the environmental conditions, such as temperature and humidity, can affect the performance of measurement instruments. Additionally, the complexity of modern systems often requires an intricate understanding of how different components interact to provide precise measurements.

To address these challenges, innovative solutions are being developed. For instance, real-time calibration techniques using artificial intelligence (AI) can automatically adjust instruments based on environmental conditions, ensuring optimal performance. Another solution involves the development of modular instruments that can be easily integrated into complex systems, enhancing overall accuracy and reliability.

Innovating with Technology: Advantages of New Measurement Solutions

New technologies, such as AI and Internet of Things (IoT), are revolutionizing the measurement industry. These innovations not only enhance the precision of instruments but also streamline the calibration and maintenance processes. AI algorithms can predict and correct inaccuracies before they become a problem, while IoT connectivity allows for remote monitoring and maintenance of instruments, reducing downtime.

By integrating these technologies, manufacturers can achieve superior performance and reduce the likelihood of errors. For example, AI-based systems can continuously monitor the performance of instruments and alert technicians of potential issues in real-time, enabling proactive maintenance.

In comparison to traditional methods, the use of these new technologies offers several advantages. Traditional calibration methods often require manual adjustments and are time-consuming, leading to longer calibration cycles. In contrast, AI-based systems can perform these tasks automatically and in a matter of minutes, significantly enhancing efficiency.

Case Studies: Real-World Applications of Advanced Measurement Instruments

One notable case study is the integration of advanced measurement instruments in the aerospace industry. Companies are leveraging high-precision instruments to ensure the accuracy of components in aircraft and spacecraft. For instance, a leading aerospace manufacturer recently unveiled a new laser interferometer capable of achieving sub-micron precision. This instrument has been used to calibrate critical components, ensuring that the aircraft's systems operate precisely as intended.

Another example is the use of atomic force microscopes in the healthcare industry. These microscopes offer unprecedented detail and can be used to study cellular structures and analyze biomaterials. A well-known healthcare provider adopted these instruments to improve the accuracy of medical devices and ensure that they meet the necessary standards for patient safety.

Conclusion: Embracing the Future of Precision Measurement

The 2025 Measurement Instrument Equipment Exhibition in Hengyang has brought together leading manufacturers and experts to showcase the latest advancements in high-precision instruments. These instruments are not only crucial for ensuring accuracy and reliability but also for driving innovation in various industries. By adopting new technologies and innovative solutions, manufacturers can overcome the challenges of precision measurement and achieve unparalleled performance.

As the exhibition continues to highlight the importance of precision and innovation, it serves as a catalyst for further advancements in the measurement industry. The future of precision measurement lies in the continuous development and integration of cutting-edge technologies, ensuring that these instruments remain at the forefront of technological progress.