Hardness Testing System for Aircraft Blades Achieves 42-Second Automation: A Journey to Streamlining Manufacturing Processes

In the modern aerospace industry, the testing and manufacturing of aircraft blades stand as a critical phase characterizing the overall quality and safety of aircraft. A groundbreaking hardness testing system, capable of completing the entire testing process in just 42 seconds, marks a significant milestone in advancing automation within this field. This leap in automation is not merely a one-off achievement but represents a broader trend towards increasing the efficiency and consistency of testing processes across the industry.

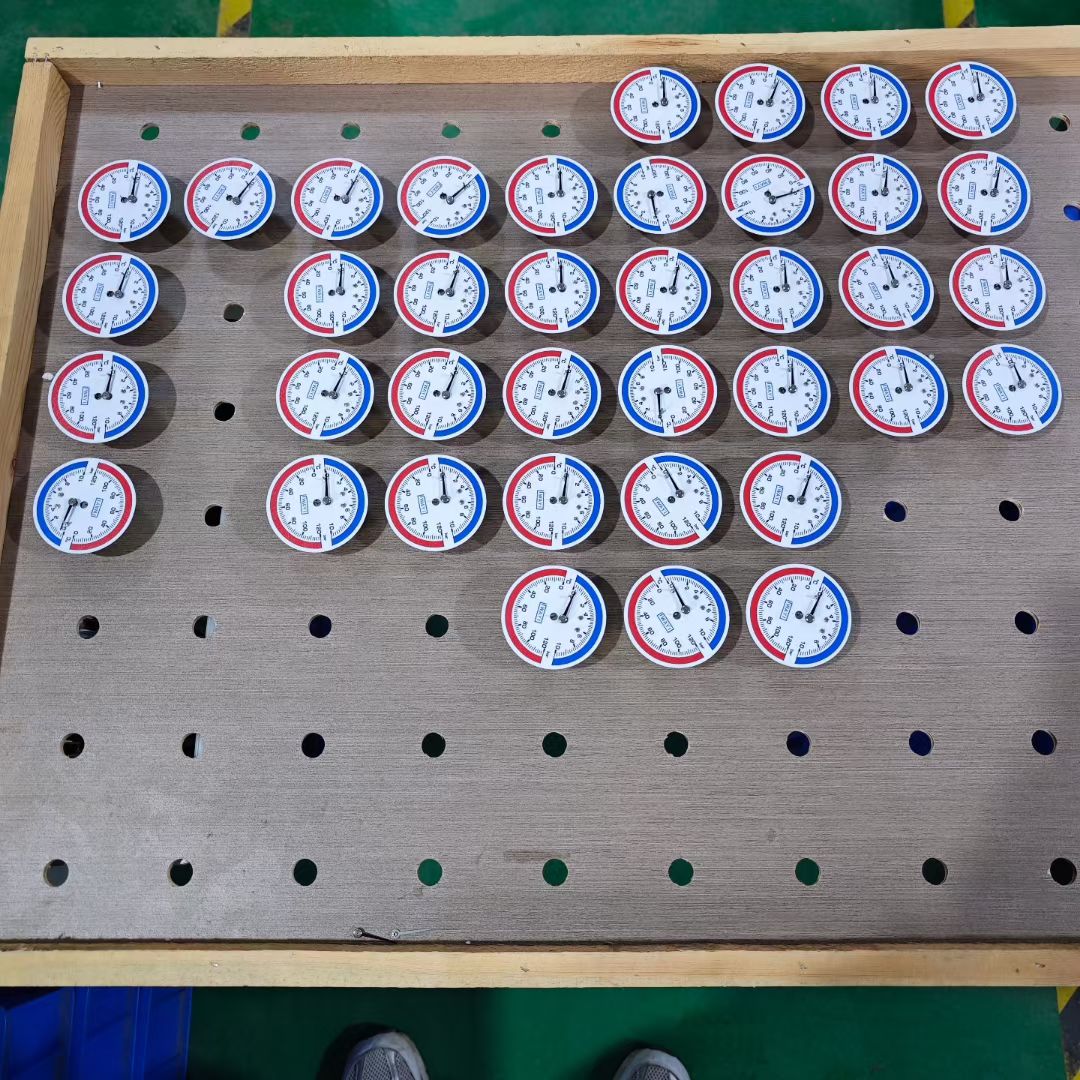

The importance of the hardness testing of aircraft blades cannot be overstated. Hardness testing ensures the physical integrity and robustness required for components subjected to extreme conditions in flight. The traditional method involves manually applying calibrated forces and measuring the indentation, which is both time-consuming and prone to human error. The new hardness testing system aims to reduce these constraints and enhance the overall quality control process.

Design Thinking and Architecture

To design such a system, we must first adhere to a thorough design thinking process. Experts in the aerospace industry have advised that a system should be characterized by its accuracy, speed, and ease of maintenance. One of the primary architectures considered for this project involved integrating high-precision sensors, advanced mechanical arms, and sophisticated software algorithms. These components work in unison to ensure that the test is both rapid and accurate.

The system architecture starts with customizable load cells and sensors, which measure the applied force during the hardness test. These signals are then transmitted to a control unit that processes the data and controls the mechanical arm’s movements. A specialized software program running on the control unit analyzes the signals in real-time, computes the hardness, and verifies the data against pre-defined standards. The data is then stored and can be analyzed for future improvements.

Component Selection

In selecting the right components, we must ensure a balance of performance and cost-effectiveness. High-quality load cells are chosen for their precision and durability, while the mechanical arm is required to be both strong and responsive. Advanced sensors are essential for capturing the smallest changes in force accurately, and the software needs to be capable of handling large volumes of data while ensuring rapid processing.

The mechanical arm, chosen from a leading supplier in the industry, features a hydraulic actuator that allows for fine-tuned movements. The load cells are custom-built to withstand the rigors of frequent testing. As for the software, it is based on open-source algorithms, allowing for customization and optimization to fit the unique requirements of the hardness testing process.

Deployment Strategy

Deploying a system of this complexity requires a structured approach. Initially, we conduct pilot testing with a small fleet of aircraft blades to validate the system’s effectiveness and reliability. During this phase, we monitor the system’s performance, address any issues, and gather feedback from testers to refine the process further.

Following the successful pilot stage, a phased deployment strategy is adopted, starting with high-priority blades in production and gradually expanding to the entire fleet. Training programs for technicians are designed to ensure they can operate and maintain the system effectively. Regular maintenance schedules are established to prevent downtime and ensure optimal performance.

Case Studies

Several airlines and aircraft manufacturers have already adopted this new hardness testing system, and initial case studies demonstrate impressive results. One notable example involves a major aircraft producer who reduced their blade testing time by 70%, translating to increased production capacity and enhanced product quality. Another case involved a regional airline that saw a 50% reduction in human error, thanks to the system's high level of automation and real-time data analysis.

Conclusion

The achievement of a 42-second hardness testing system marks a significant step in the automation of aircraft blade testing processes. By combining advanced hardware with sophisticated software, and utilizing a thoughtful deployment strategy, the system has proven capable of enhancing both speed and accuracy. This represents more than just a technological advancement; it is a testament to the ongoing efforts to improve the aerospace industry's efficiency and safety. As this trend continues to evolve, the industry can look forward to further innovations that will further streamline and optimize these critical processes.