Action Plan for Quality Improvement in the Instrumentation Industry: A Comprehensive Guide

Understanding the Challenges in the Instrumentation Industry

The instrumentation industry, one of the most critical sectors in manufacturing, has seen significant challenges in ensuring product quality. These challenges are multifaceted, driven by the rapid advancements in technology, increasing demand for precision, and the need to maintain regulatory compliance. In this industry, quality issues can lead to costly rework, downtime, and ultimately, reduced customer satisfaction. A robust action plan is essential to address these challenges and improve the overall quality of instrumentation products.

The Impact of Quality Issues on the Instrumentation Industry

Poor quality in instrumentation can have far-reaching consequences. Firstly, product failures can lead to financial losses due to recalls and customer dissatisfaction. Secondly, maintenance requirements and repair costs may rise, adding to the operational expenses. Additionally, failure to meet regulatory standards can result in legal penalties and damage to the company's reputation. Consistency in quality is therefore paramount for survival and growth in this competitive market.

Steps to Enhance Quality in the Instrumentation Industry

Review Current Quality Management SystemsThe first step is to assess the existing quality management system (QMS) thoroughly. This includes reviewing current processes, identifying gaps, and understanding areas that need improvement. Effective QMS should cover all aspects of production, from raw material sourcing to final product inspection.

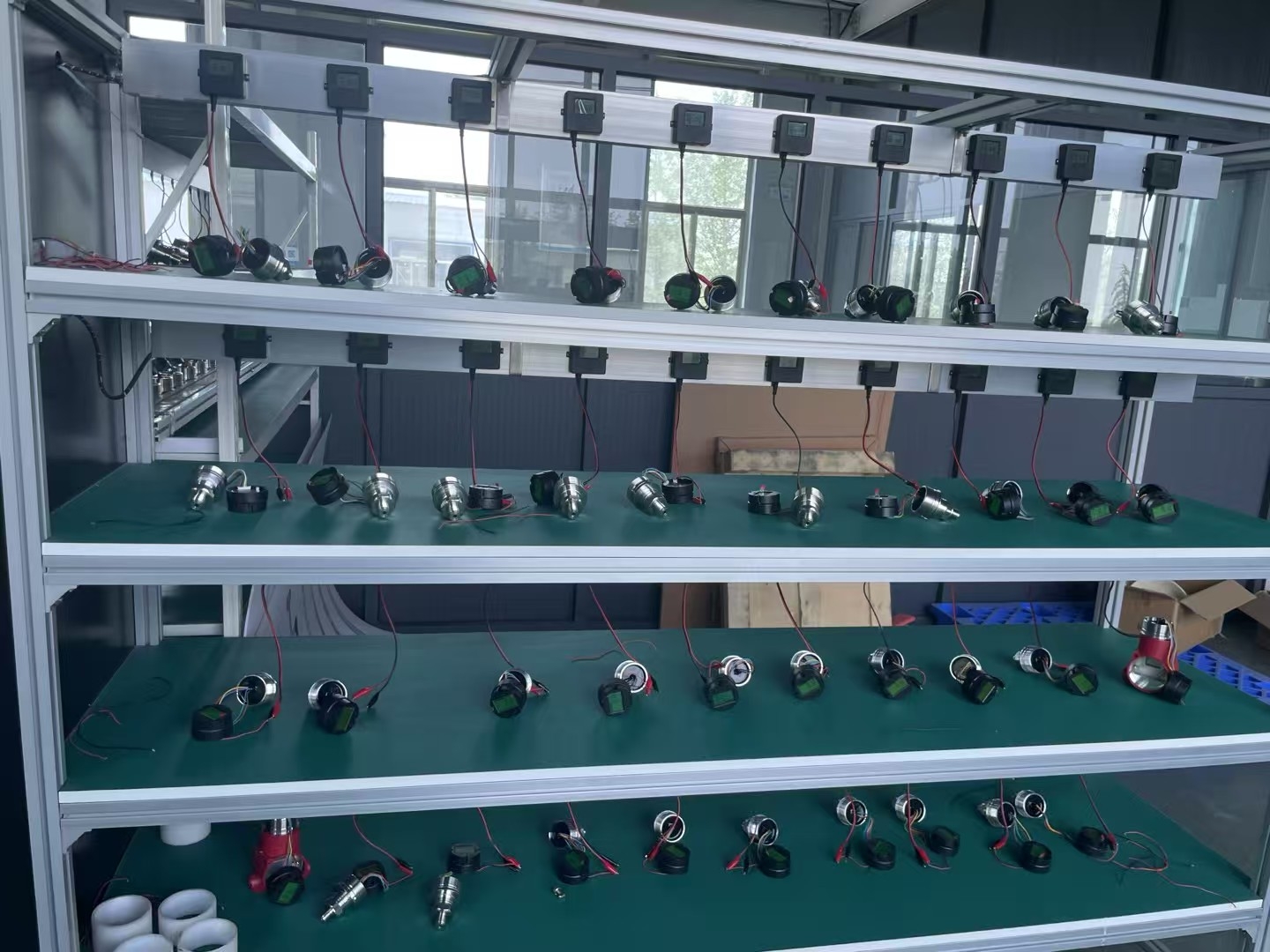

Implement Robust Inspection ProtocolsImplementing rigorous inspection protocols is crucial. This involves training staff to use inspection tools effectively and establishing clear inspection criteria. Investing in advanced inspection equipment can also provide more accurate and consistent results.

Enhance Supplier RelationshipsWorking closely with suppliers is key to ensuring quality at the source. Supplier audits should be conducted regularly to ensure they meet the required quality standards. Encouraging communication and setting clear expectations can help maintain supplier performance.

Foster a Culture of QualityCreating a quality-focused culture within the organization is vital. Training employees at all levels on quality standards and the importance of quality can instill a sense of responsibility and ownership. This can lead to better adherence to quality procedures and a proactive approach to preventing defects.

Continuously Improve ProcessesContinuous improvement is essential in the relentless pursuit of quality. Implementing a DMAIC (Define, Measure, Analyze, Improve, Control) methodology can help systematically identify and resolve quality issues. Regular feedback loops and performance reviews can also drive ongoing improvements.

Comprehensive Plan: An Integrated Approach

To truly enhance quality in the instrumentation industry, an integrated approach is necessary. This involves addressing organizational structure, process efficiency, and technological advancements. A detailed action plan should be developed, with specific timelines and responsibilities assigned to each team member. Regular progress reviews and adjustments should be made to ensure the plan remains effective.

Leadership and Organizational Structure

Senior management should lead the quality improvement initiative. Clear roles and responsibilities should be defined to ensure accountability. Teams should be organized to focus on specific areas of improvement, such as design, manufacturing, and inspection.

Process Efficiency and Technological IntegrationStreamlining processes and integrating new technologies can significantly improve quality. This includes adopting automated inspection systems, implementing predictive maintenance, and using data analytics to identify trends and patterns.

Customer Feedback and Continuous ImprovementCustomer feedback is invaluable in understanding real-world performance and identifying areas for improvement. Regular surveys and feedback sessions can help refine products and processes. Continuous improvement initiatives should be driven by customer needs and expectations.

Conclusion: A Path to Better Quality

In conclusion, quality improvement in the instrumentation industry requires a strategic and coordinated effort. By following a well-defined action plan, companies can enhance product quality, reduce costs, and maintain customer satisfaction. A commitment to quality not only benefits the business but also ensures that instrumentation products meet the highest standards of reliability and precision. This comprehensive guide provides a foundation for implementing these improvements in a practical and effective manner.