Regeneration Method for Chromatographic Column Efficiency Decline: A Comprehensive Guide

Chromatographic columns are pivotal in many analytical laboratories, providing precise separation and detection of compounds. However, their efficiency can decline over time, particularly due to accumulation of impurities and degradation of stationary phases. This can significantly impact the quality of analytical data, necessitating regular maintenance and regeneration. In this article, we will explore various methods for regenerating chromatographic columns to restore their efficiency.

Understanding the Importance of Regeneration

Chromatographic columns serve as a specialized type of tubular device used to separate mixtures based on differential partitioning between a stationary phase and a mobile phase. Over prolonged use, the stationary phase can become contaminated with analytes, causing efficiency reduction. This is often observed through increased retention times and decreased resolution. Regular regeneration helps in maintaining the column’s capacity to produce consistent and accurate data.

Key Steps in Chromatographic Column Regeneration

To effectively regenerate a chromatographic column, one needs to follow a well-defined process to ensure that the efficiency is restored without compromising the column’s integrity. This involves several steps such as dissolving blockages, removing contaminants, and reactivating the stationary phase.

Dissolving Blockages

Blockages in the column can arise from residual analytes or particulate matter. Dissolving these blockages is crucial for improving the flow rate and separation efficiency. Typically, this involves using a solvent that can dissolve the contaminants without damaging the stationary phase. A common approach is to flush the column with a strong eluent or an appropriately chosen solvent.

Removing Contaminants

Contaminants, such as residual analytes or non-polar residues, can be removed by washing the column with suitable solvents. These solvents should be chosen based on their ability to dissolve the contaminants and their compatibility with the stationary phase. For reversed-phase columns, methanol or acetonitrile might be effective. For reversed-phase C-18 columns, a mixture of acetonitrile and water is often used.

Reactivating the Stationary Phase

After contaminants have been removed, the stationary phase needs to be reactivated to ensure optimal performance. This can be achieved by flowing specific reagents through the column. For reversed-phase columns, acetonitrile is often used for this purpose. For anion-exchange columns, solutions of organic bases or acids can help reactivate the ion-exchange resin.

Choosing the Right Tools for Column Regeneration

Selecting the right tools for regenerating chromatographic columns is crucial for achieving consistent results. Here are some key considerations:

Flow Controllers

Flow controllers ensure that the eluent or reagents are introduced at a controlled and consistent rate. Proper flow rate is essential for effective dissolution and removal of blockages and contaminants. Automated flow controllers can provide precise control, reducing the risk of introducing errors during the regeneration process.

Temperature Control Devices

Some regeneration processes require specific temperature conditions to activate certain stationary phases or to improve the dissolution of contaminants. Temperature control devices, such as heating or cooling baths, can provide the necessary temperature regulation.

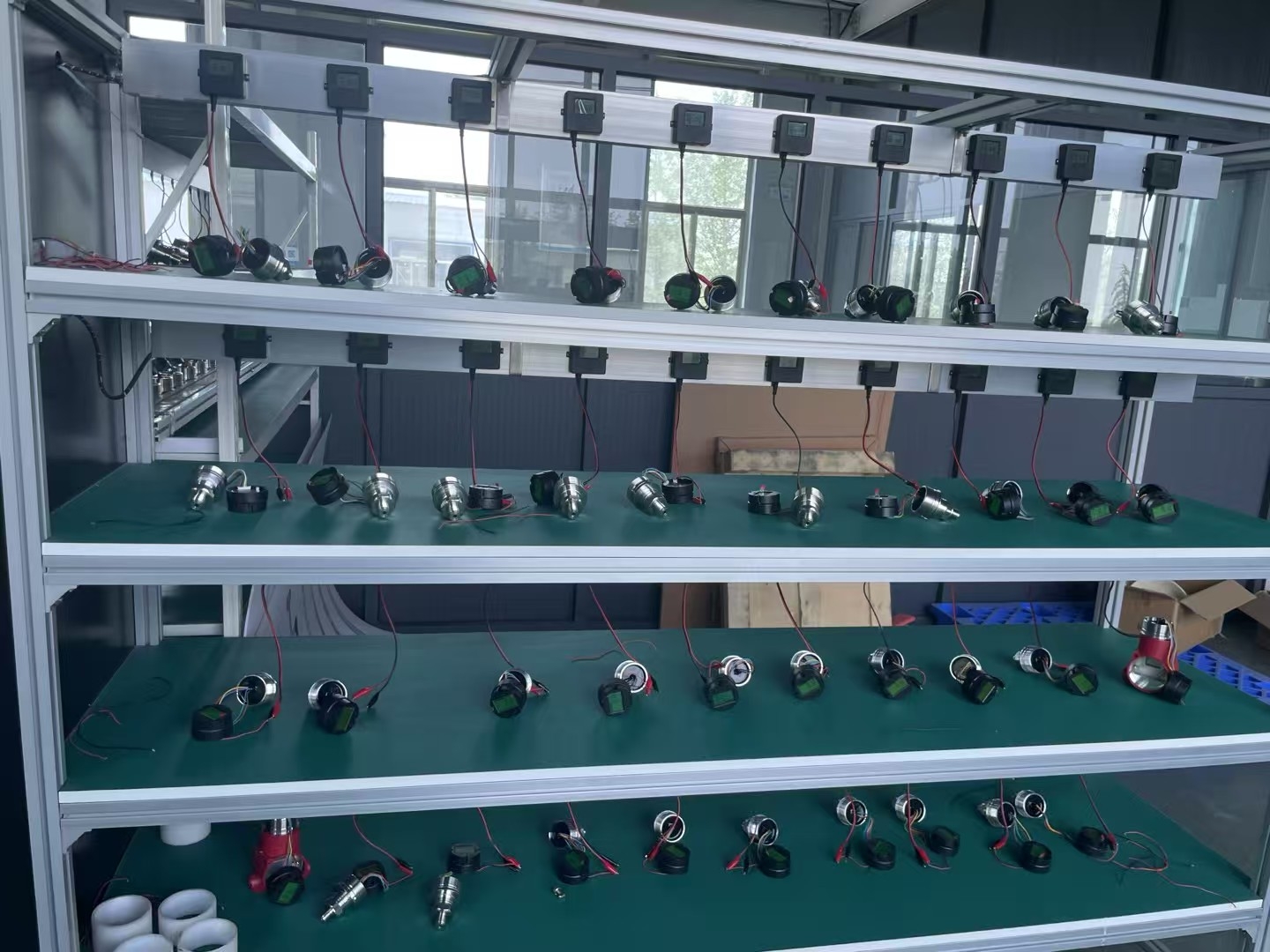

Automated Regeneration Systems

Automated systems can streamline the column regeneration process, reducing the risk of human error and ensuring consistency. They often include predefined protocols for different types of columns and solvents, making it easier to follow the right steps during the regeneration process.

Analyzing Test Results

After regenerating the column, it is essential to analyze the results to confirm the success of the process. This involves:

Evaluating Chromatograms

Visual inspection of chromatograms can provide immediate feedback on whether the column regenerations were effective. Improved peak shape, resolution, and retention times are signs of successful regeneration.

Precision and Accuracy Tests

More rigorous methods, such as precision and accuracy tests, can provide a quantitative measure of the column’s performance. Comparing the results before and after regeneration can help assess the extent of improvement.

Case Study: Handwritten Guidelines for Column Regeneration

To better illustrate the practical aspects of column regeneration, let's consider a case study based on the techniques described.

Case Study Overview

A company specialized in environmental analysis experienced declining column efficiency in their reversed-phase HPLC systems. The columns were prone to blockages due to non-polar residues, leading to increased retention times and poor resolution.

Regeneration Protocol

- Flushing with Methanol: The column was first flushed with methanol for 30 minutes to remove any residual polar residues.

- Dissolving Blockages with Acetonitrile: The column was then flushed with 100% acetonitrile for an additional 30 minutes to dissolve any blockages.

- Reactivating the Stationary Phase: The column was reactivated by flushing with a 50:50 acetonitrile and water mixture for another 30 minutes.

Test Results

After regeneration, the chromatograms showed significantly improved resolution and diminished tailing. Retention times were consistent across multiple runs, indicating a successful regeneration.

Best Practices and Conclusion

Regular regeneration of chromatographic columns is vital for maintaining their efficiency and ensuring the reliability of analytical results. Following a well-defined protocol, using the right tools, and carefully analyzing the results are key to achieving successful regeneration. By adhering to these best practices, laboratories can extend the useful life of their columns and maintain high-quality analytical performance.