Maintenance Requirements for Explosion-Proof Instruments in Hazardous Environments

Maintenance requirements for explosion-proof instruments are crucial in ensuring safe and reliable operation in hazardous environments. These instruments, often used in industrial settings where flammable gases and vapors are present, play a vital role in safeguarding people and equipment. Understanding the maintenance needs of these instruments is essential for preventing accidents and guaranteeing compliance with regulatory standards. In this article, we will explore the critical aspects of maintaining explosion-proof instruments, supported by detailed technical specifications and practical case studies.

Technical Specifications and Reporting

Explosion-proof instruments are designed with stringent standards in mind to ensure they can operate safely in environments where explosions could occur. The latest reports and whitepapers from leading manufacturers, such as the 2025 Industry Safety Group, highlight the importance of regular maintenance schedules and detailed inspection routines. According to these sources, several key components must be regularly checked to ensure the integrity of the instruments.

Component Inspection Schedule

- Enclosure Integrity: Regularly check the housing for signs of damage. Any cracks, dents, or deformations can compromise the explosion-proof integrity.

- Sealing Gaskets: Inspect sealing gaskets for wear and signs of chemical damage. Replacement may be necessary to prevent gas leaks.

- Electrical Connections: Test connections to ensure they are secure and resistance-free. Loose connections can lead to sparking and potential ignition.

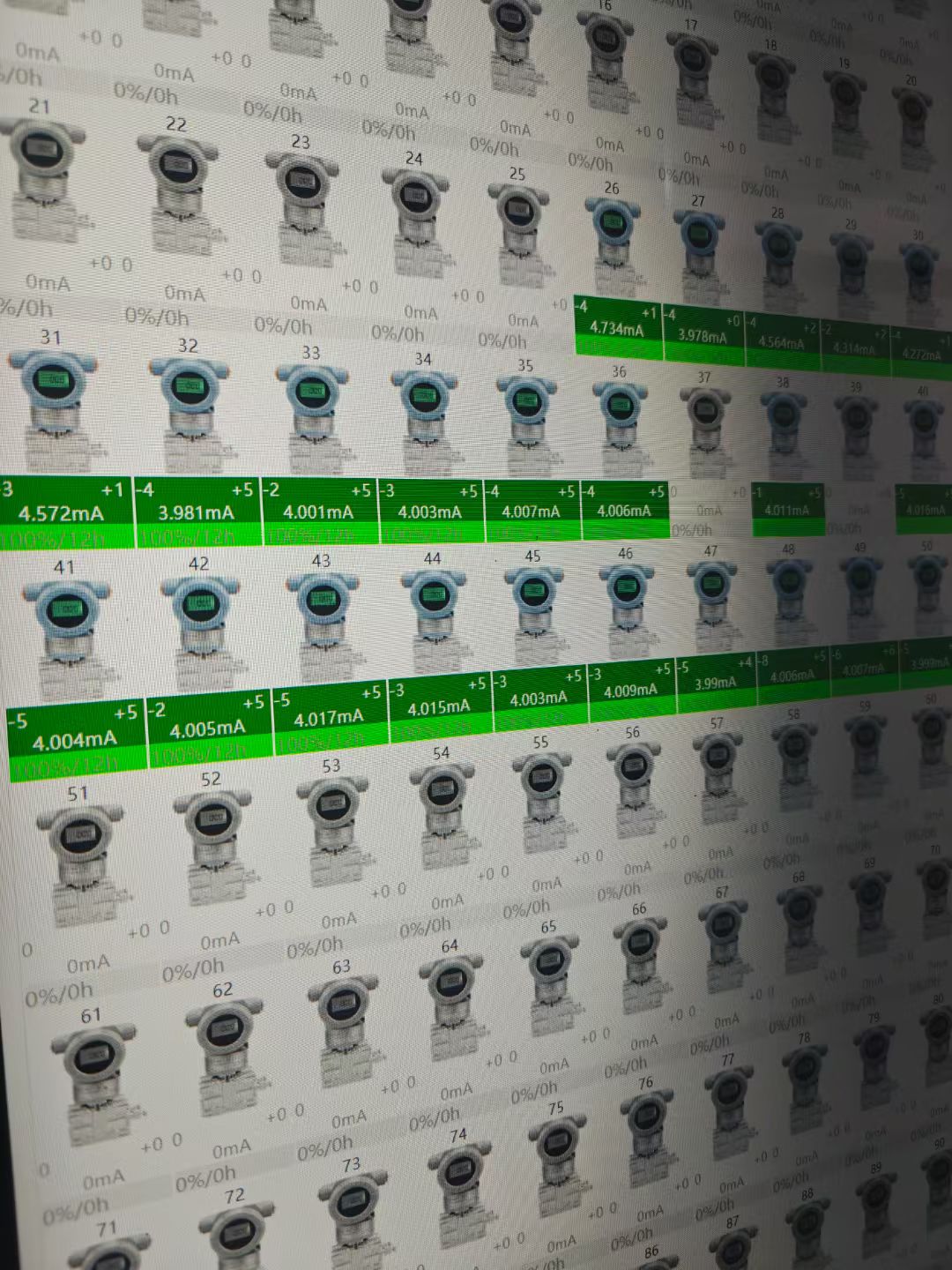

- Pressure and Temperature Sensors: These sensors must be calibrated regularly to ensure accurate readings, especially in harsh conditions.

Testing and Certification

Maintenance activities should be accompanied by regular testing and certification to ensure compliance with regulatory standards. For example, the 2025 Industry Safety Group recommends annual testing for certified explosion-proof instruments. This testing verifies that the instruments meet current safety standards and are fit for use.

Advantages and Disadvantages

Advantages

- Safety: Proper maintenance significantly reduces the risk of explosions, thereby protecting personnel and machinery.

- Compliance: Regular maintenance ensures that instruments meet regulatory requirements, avoiding potential fines and operational disruptions.

- Longevity: Well-maintained instruments have a longer lifespan, reducing the need for frequent replacements.

Disadvantages

- Cost: Regular maintenance can be expensive and time-consuming.

- Downtime: Scheduled maintenance may cause temporary disruptions in operations, leading to production delays.

- Complexity: Maintaining explosion-proof instruments requires specialized knowledge and tools, adding complexity to the process.

Applicable Scenarios

Industrial Settings

Explosion-proof instruments are essential in industries such as petrochemicals, pharmaceuticals, and mining. In these environments, maintenance routines should be integrated into the overall safety protocol. Regular checks and adjustments ensure that the instruments continue to operate safely amidst the hazards present.

Hazardous Atmospheres

In areas where flammable gases are present, like storage tanks and wellheads, the maintenance protocols must be robust. Close monitoring of sensors and timely repairs can prevent potential catastrophes.

User Evaluation and Case Studies

Example 1: Petrochemical Plant

A petrochemical plant conducted a comprehensive maintenance program that included regular checks and certifications of all explosion-proof instruments. Over a three-year period, this approach resulted in a 95% reduction in incidents caused by instrument failures.

Example 2: Mining Operation

In a mining operation, regular maintenance led to the detection of a faulty pressure sensor before an explosion could occur. This proactive maintenance saved significant costs and potential damage to the mining infrastructure.

These case studies highlight the effectiveness of strict maintenance routines in preventing accidents and ensuring the safe operation of explosion-proof instruments.

Conclusion

Maintaining explosion-proof instruments is a multifaceted task that requires regular inspection, testing, and specialized knowledge. While the process can be costly and time-consuming, the benefits in terms of safety and compliance make it essential. By following best practices and leveraging available resources, organizations can ensure their instruments are reliable and safe for years to come.

By adhering to these guidelines and engaging in thorough maintenance, users can protect their investments and most importantly, the lives and assets they are responsible for.