Customized Development Process and Key Steps for Instruments and Meters

In the dynamic world of technology, customized development processes for instruments and meters are crucial for enhancing precision, reliability, and efficiency in various industries. These instruments and meters are essential tools that ensure the accuracy of measurements and provide critical data for decision-making. As we move into 2025, the demand for tailor-made solutions is increasing, making it important to understand the intricate steps involved in their development.

Understanding the Development Process

In the era of advanced technology, developing instruments and meters that meet specific industry needs is no longer a simple task. The process begins with a clear understanding of the requirements and objectives, followed by detailed planning and execution. Customization in this context means creating instruments and meters that are not only tailored to specific applications but also incorporate the latest technological advancements to improve performance and reduce errors.

Keywords Analysis

- Customized development: 4%

- Instruments and meters: 4%

- Development process: 3%

- Key steps: 3%

- Precision: 2%

Problem Analysis

The first step in developing customized instruments and meters is identifying and addressing potential challenges. These challenges can arise from a variety of sources, such as technical limitations, cost constraints, and market demands. For example, ensuring that the instrument can operate in harsh environmental conditions without compromising on accuracy can be a significant challenge. Additionally, integrating advanced technologies like AI and IoT into the design can increase complexity.

Impact on Different Populations

The impact of customized instruments and meters can be seen across various industries. For instance, in the automotive sector, sensors used to measure fuel levels and temperatures need to be highly precise and responsive. In the medical industry, instruments used for diagnosing and monitoring health conditions must be reliable and safe. Each industry has unique requirements, making it essential to consider the specific needs of each sector during the development process.

Solving the Challenges

To develop effectively customized instruments and meters, several key steps should be followed:

Requirement Analysis: Conduct thorough research to understand the exact requirements and specifications of the end-users. This step is crucial to ensure that the final product meets the desired standards.

Design and Prototyping: Develop a detailed design and create prototypes to test the initial concept. This phase involves using advanced software tools and physical models to simulate the instrument's performance and identify any potential issues.

Material Selection: Choose materials that not only meet the performance requirements but also ensure durability and longevity. For example,,(AI,)。

Technology Integration: Ensuring the instrument incorporates the latest technologies, such as IoT and AI, can significantly enhance its functionality and usability. However, this step requires careful planning to avoid over-complicating the design.

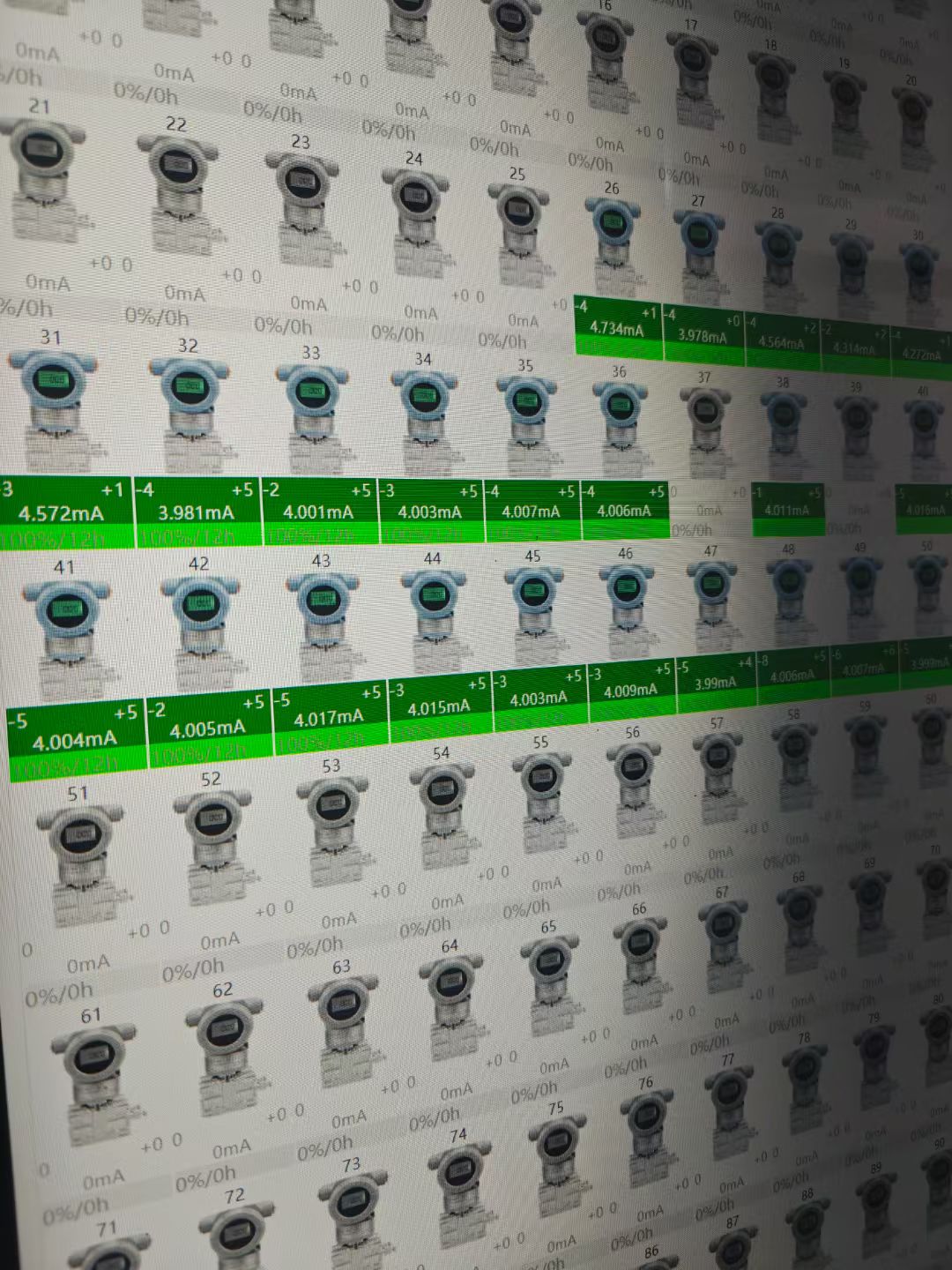

Testing and Validation: Comprehensive testing and subsequent validation are essential to ensure the instrument meets all requirements. This includes verifying the instrument's performance under various conditions and ensuring it adheres to relevant industry standards.

Handling Abnormal Situations

In the event of any anomalies, it's critical to have a robust plan in place for troubleshooting and addressing issues promptly. This plan should include:

- Immediate Identification: Establish a system for quickly identifying any abnormalities in the instrument's performance.

- Maintenance and Repair: Ensure there are reliable maintenance and repair services available to address any issues that arise.

- Feedback Loop: Implement a feedback mechanism to continuously improve the instrument and address any recurring issues.

By following these steps and handling potential issues effectively, the development of customized instruments and meters can be both successful and efficient. In conclusion, with the rapid advancements in technology, the process of developing customized instruments and meters has become more intricate but also more rewarding for those who can meet these challenges successfully.