Analysis and Maintenance of Power Supply Faults in Instruments and Meters: A Comprehensive Guide

In 2025, a stable power supply is crucial for maintaining the accuracy and reliability of instruments and meters, especially in high-precision applications. Unstable power supplies can lead to measurement errors, which can have significant consequences in fields such as manufacturing, scientific research, and clinical testing. This article aims to provide a detailed guide on identifying and resolving common power supply faults in instruments and meters.

Understanding Power Supply Systems

The power supply system in instruments and meters is like the heart that ensures every component operates optimally. It is essential to understand the basics of power supply design to troubleshoot effectively. A typical power supply system includes rectification, filtering, voltage regulation, and conversion stages. Rectification converts AC to DC, filtering smoothens the DC voltage, voltage regulation maintains a stable output, and conversion adjusts the output voltage to the required level.

Identifying Faults

Identifying faulty power supplies can be a daunting task, but with the right approach, it becomes much simpler. Here are some common signs of power supply issues:

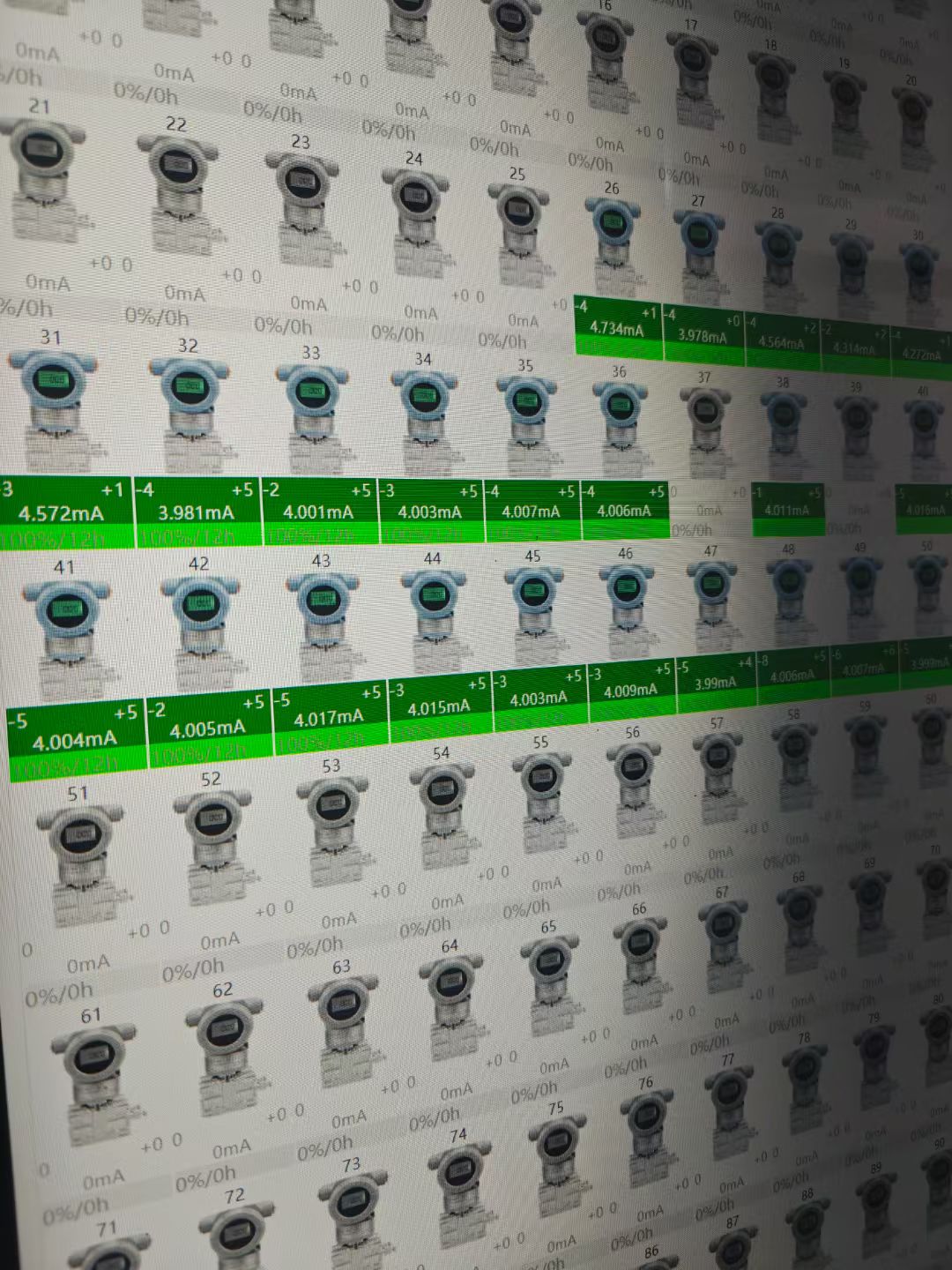

- Unstable readings: Fluctuations or erratic behavior in the instrument's output can indicate a faulty power supply.

- Ringing or buzzing: Audible noise from the instrument or meter can signal a problem with the power supply filtering.

- Overheating: Heat from the power supply unit can point to inefficient voltage regulation or excessive load demands.

Diagnosing the Problem

Testing Standards and Expert Opinions

According to the IEC 61000 series, power quality must meet strict standards for both voltage and frequency stability. Experts recommend conducting a series of diagnostic tests to isolate the problem. Before testing, ensure that the instrument is operating under standard conditions: temperature, humidity, and load.

Workflow Design and Tool Selection

To maintain operational integrity, follow a structured testing procedure:

- Primary Power Supply Inspection: Check for voltage droop and ripple using a multimeter. A ripple voltage greater than 20 mV typically indicates a problem.

- Component Testing: Use an oscilloscope to examine the output waveforms of the power supply. Look for any distortions or anomalies.

- Load Test: Apply a known load to the instrument and monitor the power supply's response. This will help determine if the power supply can handle real-world conditions.

Practical Examples

Consider a scenario where an ECG machine is reporting inconsistent readings. After performing a primary power supply inspection, it was found that the ripple voltage was 30 mV, significantly higher than the acceptable threshold of 20 mV. Further testing with an oscilloscope revealed a distorted output waveform. When a typical load was applied, the power supply failed to maintain a stable output.

In this case, it was determined that the filter capacitor needed to be replaced. Additionally, the voltage regulator was found to be malfunctioning, requiring a replacement as well. The ECG machine now operates with stable and accurate readings.

Maintaining Power Supply Health

Regular maintenance is key to extending the lifespan of your instruments and meters. Below are some best practices:

- Regular Cleaning: Clean the power supply unit to avoid dust accumulation, which can affect heat dissipation.

- Component Replacement: Replace aged or failing components, especially capacitors and resistors.

- Routine Testing: Schedule periodic testing to identify and address potential issues before they become problematic.

Conclusion

In 2025, ensuring the integrity of power supply systems in instruments and meters is paramount. By following a comprehensive approach to diagnosis and maintenance, you can significantly enhance the reliability and accuracy of your equipment. Remember, a stable and efficient power supply is the backbone of any precision measurement system.