Cases of Technological Innovation and Breakthrough in the Instrumentation Industry

The instrumentation industry has seen remarkable advancements over the last few years, driven by rapid technological innovation. As we approach 2025, new tools and methodologies are transforming the way we design, test, and deploy instrumentation systems. This article will focus on several cutting-edge cases that have pushed the boundaries of what is possible in this field.

From the initial stages of research to the final deployment, technology is redefining the landscape of the instrumentation industry. Experts in the field are collaborating with industry leaders to develop novel solutions that address current challenges and open up new possibilities. This article will guide you through how these innovations are being implemented, the tools and methods used, and how to interpret the results to ensure the best outcomes.

Understanding the Testing and Validation Process

In the early stages of development, researchers and engineers often use simulation tools to predict the performance of their instrumentation systems. The simulation approach allows for detailed analysis under various conditions without the need for physical prototypes. 2025 saw the introduction of sophisticated software that can simulate complex systems, providing a deep understanding of how different components will interact under real-world scenarios.

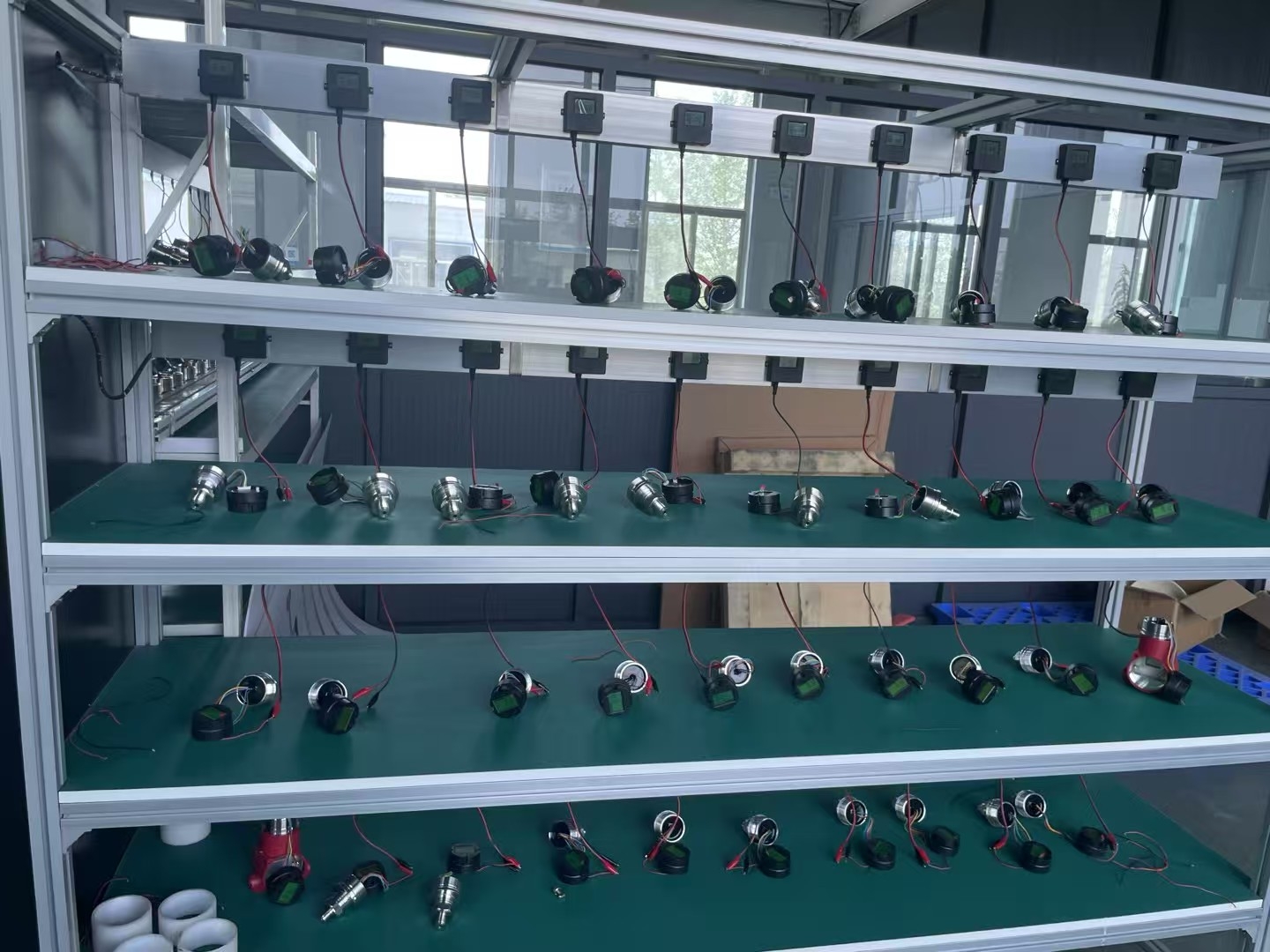

Once the initial simulations are complete, physical prototypes are either constructed or tested using existing setups. Engineers employ performance testing methodologies to verify the functionality and reliability of the prototypes. This involves subjecting the systems to a range of conditions, from typical usage to extreme scenarios. Testing data is meticulously recorded and analyzed to ensure that the system meets the required standards.

A critical aspect of this process is the integration testing phase, where various components are combined and tested as a whole. This ensures that all parts work seamlessly together and that the system as a whole functions as intended. The goal is to identify any potential issues at an early stage, allowing for timely corrections and optimizations.

Leveraging Advanced Tools and Techniques

One of the standout breakthroughs in the instrumentation industry is the advent of AI-driven predictive analytics. These tools use machine learning algorithms to predict potential failures in instrumentation systems by analyzing past performance data. The 2025 tools are highly sophisticated, capable of identifying subtle patterns that would be difficult for human engineers to detect.

Another key tool is Internet of Things (IoT) connectivity, which enables real-time monitoring and control of instrumentation systems. IoT devices can collect data from various parts of a system and send it to a central hub, where it is aggregated and analyzed. This allows for proactive maintenance and troubleshooting, reducing downtime and improving overall system efficiency.

Non-destructive testing (NDT) is another area where significant advancements have been made. Techniques like ultrasonic testing and magnetic particle inspection allow engineers to assess the condition of materials and components without causing damage. These methods are particularly useful in industries where the cost of downtime is high, such as manufacturing and energy.

Analyzing Test Results and Case Studies

Analyzing the test results is crucial for validating the performance of instrumentation systems. In 2025, engineers commonly use data visualization tools to represent test data in an understandable format. These tools can highlight trends, anomalies, and performance metrics that are essential for making informed decisions.

A notable example is the case of the smart water meter. Traditionally, water meters were mechanical and required periodic manual readings. However, with modern instrumentation technology, water meters are now equipped with IoT connectivity and AI-driven analysis. A case study found that these smart meters not only provided accurate and real-time water usage information but also helped in detecting leaks and potential faults efficiently.

In another example, a factory automation system was redesigned to incorporate advanced sensors and control systems. The tests showed a significant improvement in production efficiency and reliability. The implementation of AI-driven predictive maintenance further reduced maintenance costs and downtime by identifying issues before they caused major disruptions.

Conclusion and Future Implications

The cases of technological innovation in the instrumentation industry underscore the profound impact of advanced tools and methodologies on system performance and reliability. As we move into 2026, it is anticipated that these trends will continue to evolve, leading to even more sophisticated and flexible instrumentation solutions.

For engineers and professionals in the field, it is essential to stay informed about the latest technologies and methodologies. By understanding the testing and validation processes and leveraging advanced tools, one can ensure that their instrumentation systems meet the highest standards of performance and reliability.

In summary, the instrumentation industry has seen a wealth of technological innovations in the last few years, and it is likely that continued progress will revolutionize the way we design and deploy instrumentation systems. By embracing these advancements, the industry can meet the growing demands of a technologically driven world.