Waterproof and Anti-corrosion Scheme for Marine Monitoring Instruments and Meters

Marine monitoring instruments and meters play a crucial role in maintaining safety and understanding the dynamics of marine environments. Ensuring these devices are both waterproof and anti-corrosion is paramount, especially in a marine setting. By 2025, the demand for reliable and durable monitoring solutions will continue to increase as environmental concerns and regulations evolve. In this article, we explore a detailed scheme designed to protect marine monitoring instruments and meters, ensuring they can withstand the challenging marine environment.

Architectural Design and Expert Guidance

The design for waterproof and anti-corrosion schemes in marine monitoring is complex but essential. In 2025, various experts recommend a modular design approach, where each component is carefully selected and integrated to ensure optimal functionality and durability. Component selection is critical; materials must be able to resist corrosion and withstand water pressure and salinity. This means choosing high-quality materials such as stainless steel, epoxy resins, and specialized coatings that can protect against saltwater corrosion.

The architectural design is based on several key principles, including redundancy and robustness. By integrating multiple layers of protection, the scheme ensures that if one layer fails, others remain intact. This design allows for adaptability, as the system can be updated or maintained without the entire device needing replacement.

Component Selection

Water-Resistant Enclosure

The water-resistant enclosure is a vital part of the scheme. This enclosure houses the sensitive electronic components and protects them from direct contact with saltwater. Modern enclosures are designed with gaskets and seals to prevent water ingress, ensuring the device remains functional even in harsh marine conditions. For best results, consider using materials like polypropylene or reinforced plastics, which are known for their water resistance and durability.

Epoxy Resins and Coatings

Epoxy resins and specialized coatings are applied to both the interior and exterior surfaces of the device. These materials provide an additional layer of protection against corrosion and chemical degradation. Epoxy resins are particularly effective because they form a strong bond with metal surfaces, creating a barrier against saltwater and other corrosive elements.

Cable Management

Waterproof and anti-corrosion cable management is just as important as the overall enclosure. Cables and connections must be carefully sealed and protected to prevent water from entering through these points. Harnesses and grommets are often used to control cable movement and provide a watertight seal.

Deployment and Maintenance Strategy

Site Selection

The location of the monitoring instruments is critical. Locations that are constantly submerged or experience strong currents require a more robust design. For those areas where the instruments are not always submerged, a simpler design may suffice. Careful site selection based on water conditions and environmental factors helps ensure the longevity of the devices.

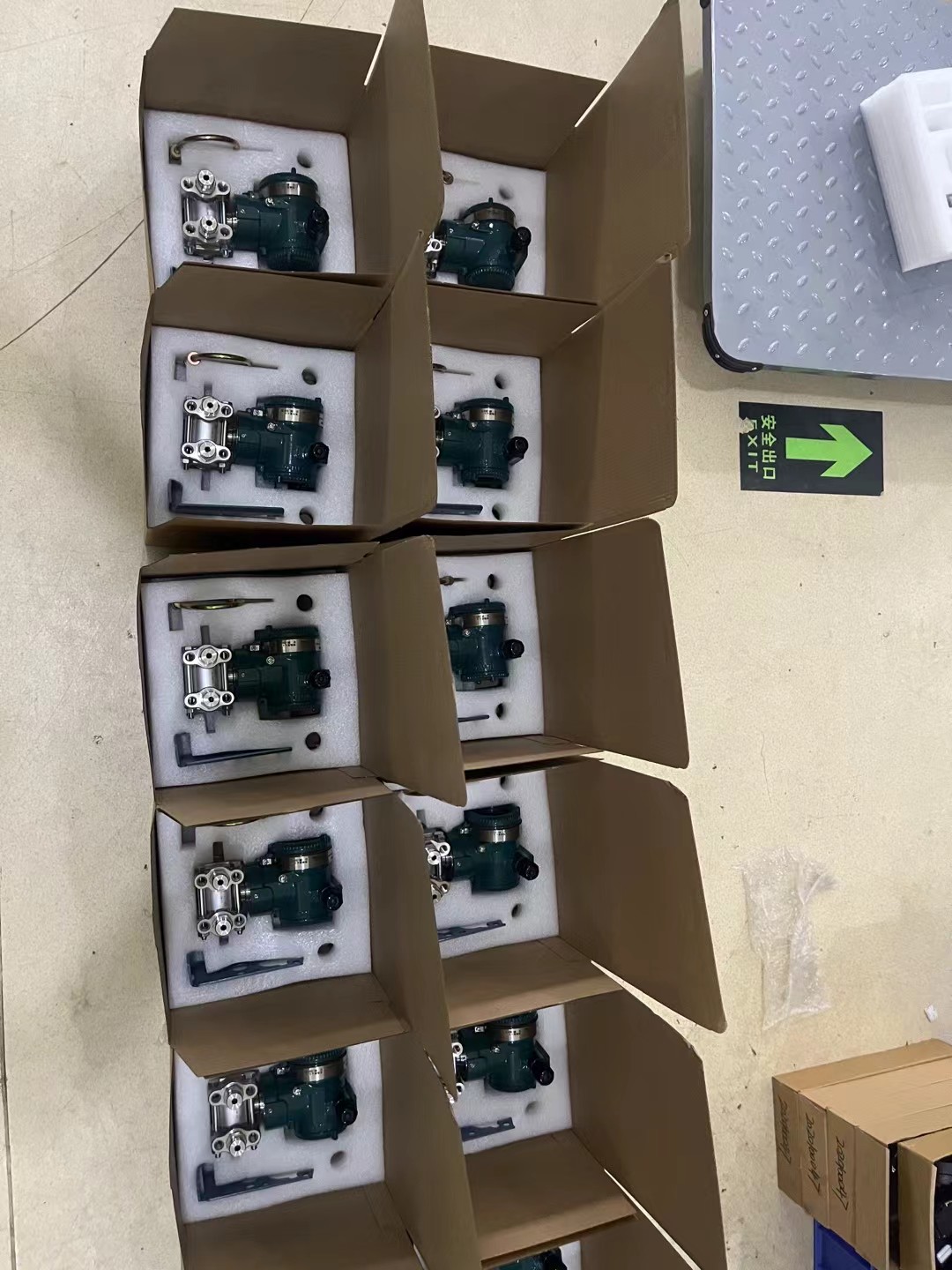

.jpg )

Regular Maintenance

Regular maintenance is essential to extend the life of marine monitoring instruments. By scheduling routine checks, the team can identify and address potential issues before they become major problems. Maintenance should include checking the integrity of the enclosure, inspecting cables for signs of wear, and reapplying any necessary coatings or resins.

Case Study: Successful Implementation

To better illustrate the importance of a well-designed waterproof and anti-corrosion scheme, let's consider a case study of a marine monitoring system deployed in the Bay of Bengal. The system was designed to monitor water temperature, salinity, and oxygen levels. It was equipped with high-quality enclosures and epoxy resins. Initial tests showed promising results, but during the first year of operation, signs of corrosion began to appear.

Upon inspection, the team found that the cable connections had not been properly sealed, allowing water to enter the device. This led to malfunctioning sensors and inaccurate data. Implementing a revised maintenance strategy and reinforcing the cable management systems resolved the issue. Over the next two years, the system performed flawlessly, providing reliable data and demonstrating the effectiveness of the waterproof and anti-corrosion scheme.

Conclusion

In conclusion, designing a robust waterproof and anti-corrosion scheme for marine monitoring instruments and meters is a multifaceted task that requires careful consideration of component selection, architectural design, and deployment strategy. By adhering to expert guidelines and implementing a comprehensive maintenance plan, the reliability and longevity of these critical devices can be significantly enhanced. The examples provided in this article underscore the importance of meticulous design and continuous attention to detail to ensure that marine monitoring systems successfully capture valuable environmental data.