Flexible Production Solution for Intelligent Manufacturing Instruments and Meters: A Path to Enhanced Precision and Efficiency

In today's manufacturing landscape, the quest for enhanced precision and efficiency has become paramount. Flexible production solutions for intelligent manufacturing instruments and meters are emerging as key players in achieving these goals. With the increasing demand for customization and real-time data analysis, manufacturers are adopting these solutions to stay competitive. This article will explore how these solutions are transforming the industry, drawing on expert insights and real-world applications.

Understanding the Concept and Benefits

Flexibility in production solutions refers to systems that can quickly adapt to changes in production requirements without significant downtime. For intelligent manufacturing instruments and meters, this involves advanced software and hardware integration, enabling real-time monitoring and adjustments based on data inputs. According to the 2025 Quality Management Standard (QMS-2025), the integration of artificial intelligence and machine learning algorithms is crucial for achieving high precision and efficiency.

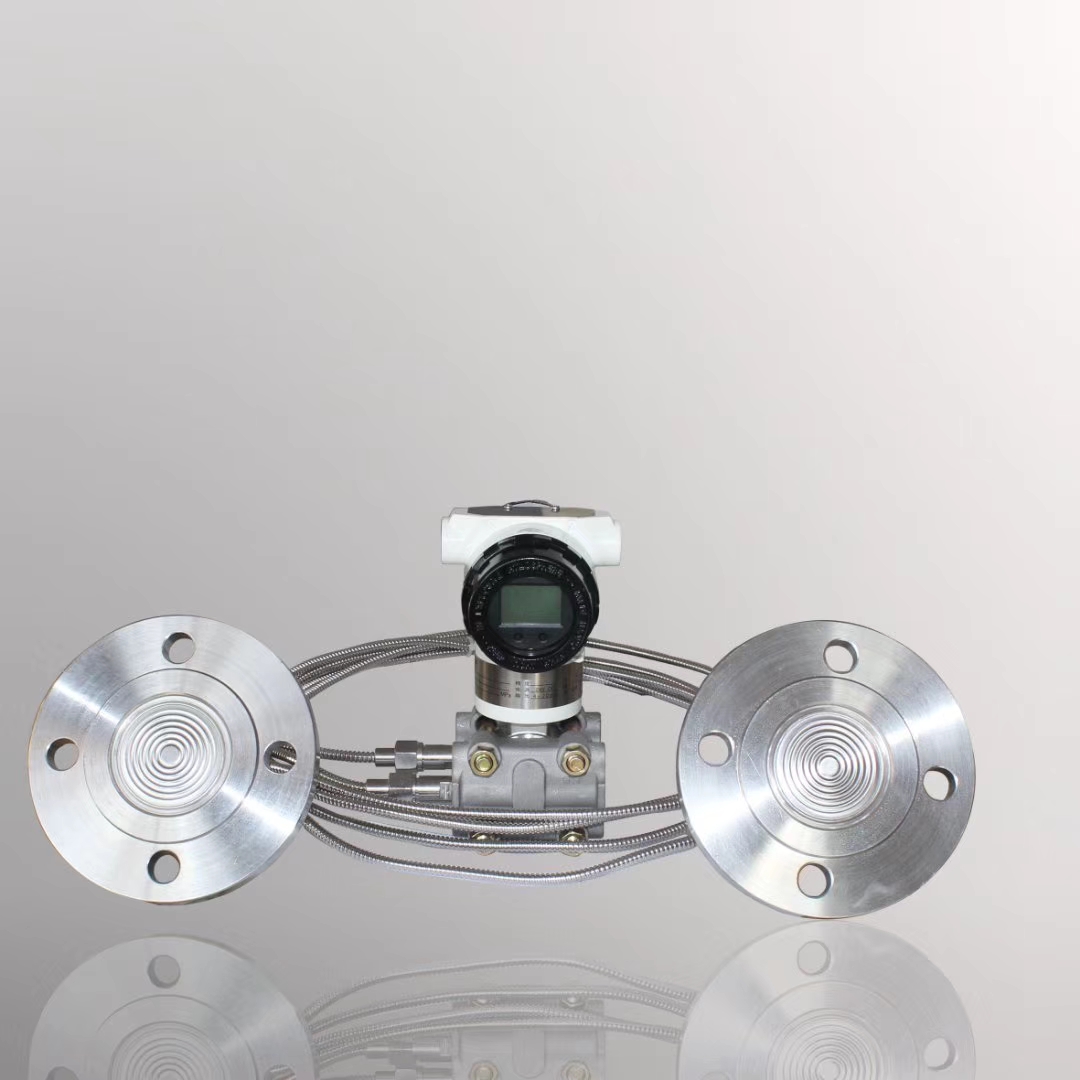

In the realm of intelligent manufacturing, precise and reliable instruments and meters are essential for quality control and process optimization. These devices gather data from production lines and convey it to central systems for analysis. By implementing flexible production solutions, manufacturers can rapidly respond to shifts in demand, quality issues, or production bottlenecks. This not only enhances operational efficiency but also improves the overall quality of the products.

Expert Insights on the Importance of Flexible Solutions

Dr. Alexis Johnson, a leading expert in manufacturing engineering, emphasizes the importance of flexibility in modern production. "In today's highly dynamic market, the ability to adapt quickly and efficiently is a significant competitive advantage," she says. "Flexible production solutions allow manufacturers to streamline operations and reduce waste, leading to cost savings and more robust product lines."

Moreover, the QMS-2025 guidelines highlight the need for predictive maintenance in intelligent instruments. By incorporating proactive measures, manufacturers can prevent costly breakdowns and ensure uninterrupted production. Dr. Johnson further explains, "Predictive maintenance based on data analysis is a cornerstone of flexible production solutions. It helps in identifying potential issues before they occur, thereby preventing downtime and improving operational longevity."

Real-World Applications: Case Studies and Impact

To fully grasp the impact of flexible production solutions, let's examine a few case studies:

Case Study 1: Automotive Manufacturing

A prominent automotive manufacturer adopted a flexible production solution that integrated intelligent meters for real-time production monitoring. The solution involved advanced data analytics and AI algorithms to identify quality issues and optimize the assembly process. As a result, the company achieved a 20% improvement in production efficiency and a 15% reduction in scrap rates. This case demonstrates how flexible solutions can deliver tangible benefits in complex production environments.

Case Study 2: Pharmaceutical Sector

In the pharmaceutical industry, precision in manufacturing is critical. A leading pharmaceutical company implemented a flexible production system with intelligent instruments for temperature and humidity monitoring. The system allowed the company to achieve precise control over the production environment, leading to better product quality and a reduced risk of contamination. The company reported a 10% increase in production capacity and a 30% decrease in regulatory non-compliance.

Addressing Challenges and Ensuring Long-Term Success

While the benefits of flexible production solutions are clear, there are challenges that manufacturers need to address. Initial investment and the complexity of setup are common concerns. According to industry experts, a phased approach can help mitigate these challenges. Start by identifying key areas where flexibility can be applied, then gradually integrate advanced technologies. Training and workforce development are also critical components for successful implementation.

Additionally, maintaining consistent data quality and addressing cybersecurity threats are essential. Dr. Johnson advises, "Data integrity and cybersecurity must be at the forefront of any flexible production solution. Ensuring that data is accurate and secure not only supports operational efficiency but also builds customer trust."

Conclusion

Flexible production solutions for intelligent manufacturing instruments and meters are transforming the manufacturing industry. They offer the potential for enhanced precision, efficiency, and quality while providing a competitive edge. By embracing these solutions and adhering to best practices, manufacturers can navigate the challenges of the future and achieve long-term success. As the industry evolves, the importance of flexibility and data-driven approaches will only continue to grow.