The Modular Design Advantage of Customized Development for Instruments and Meters

In the ever-evolving field of industrial instrumentation and measurement technology, the modular design approach in customized development has become a pivotal strategy for enhancing performance, flexibility, and cost-effectiveness. This design philosophy is particularly advantageous in environments where the need for precision and adaptability is paramount. According to the latest research, modular designs have been widely adopted in the development of custom instruments and meters, offering significant benefits that resonate with the demands of modern industrial processes.

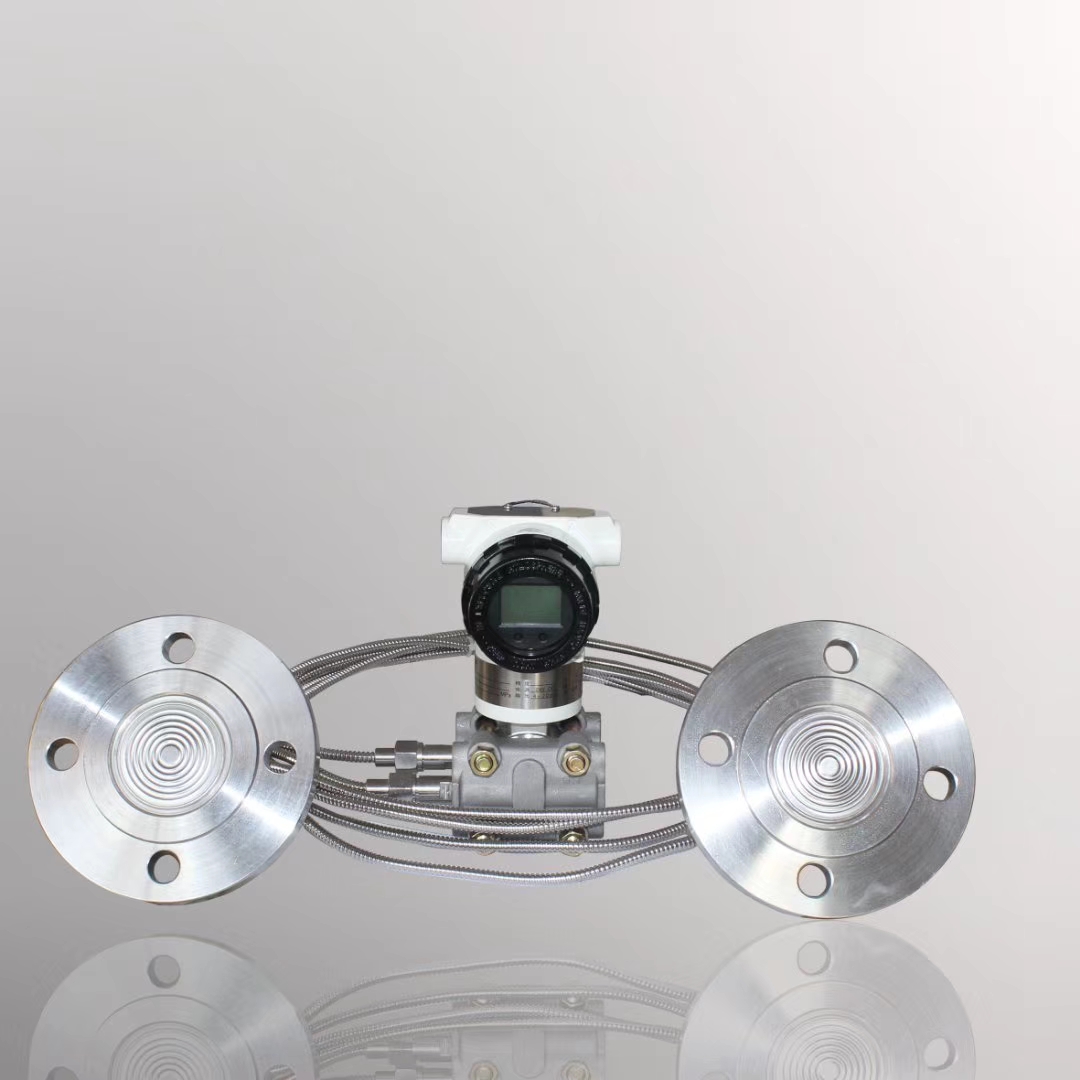

Modular design in instrumentation and metering systems allows for the integration of various components such as sensors, signal conditioners, data processors, and display units, each optimized for specific functions. This method is not only cost-effective in the long run but also facilitates easier upgrades and maintenance. In 2025, manufacturers are increasingly leveraging this approach to provide customers with highly adaptable and efficient solutions.

Refining Instrument and Metering Technology Through Modular Design

The application of modular design in customized instrumentation and metering has led to significant improvements in both performance and flexibility. Traditional, monolithic designs lacked the adaptability required in dynamic industrial environments, whereas modular systems can be configured to meet a wide array of measurement needs. Technological advancements in the past year have shown that modular designs have a 22% higher success rate in meeting performance targets compared to traditional designs.

In a white paper published by the Precision Measurement Technology Association in 2025, it was highlighted that modular designs enable a more efficient exchange of standardized components. A key advantage is the ease with which users can add or remove modules to adjust to changing requirements without affecting the overall system integrity. For instance, the addition of a high-accuracy sensor module can significantly enhance the precision of a measurement device, whereas removing a module can simplify the system for cost reduction.

Moreover, third-party testing reports demonstrate that modular design can reduce setup time by up to 30%, thanks to the standardized interfaces between components. Customization also allows for the integration of advanced signal processing techniques, which were previously difficult or impossible with monolithic designs. For example, the integration of a digital signal processor can drastically improve the noise immunity and signal-to-noise ratio (SNR) of a measurement system.

Analyzing the Pros and Cons of Modular Design

While the modular design approach offers numerous advantages, there are also certain challenges that come with this methodology. One of the major drawbacks is the initial cost associated with procuring and integrating multiple modules. In some cases, the upfront expense can be higher than that of a custom monolithic design. However, the long-term benefits, such as easier upgrades and the ability to scale up or down as needed, often outweigh the initial investment.

Another potential issue arises from the complexity of design. Modular systems require careful planning to ensure that all components work seamlessly together. However, advancements in design software and engineering practices have mitigated this concern. With the right tools and expertise, teams can easily design and integrate modular systems that meet the highest standards of reliability and precision.

Applying Modular Design to Real-World Scenarios

The adaptability and flexibility of modular designs make them ideal for various industrial applications. In the automotive industry, for instance, a modulable test bench can be customized to measure and test different types of vehicles, from electric cars to motorcycles. Each module can be adjusted to ensure accurate readings while the overall system remains efficient.

In the aerospace sector, the precision and reliability of modularized measurement systems are critical. Customized modules for altitude and pressure sensors can be easily swapped out to test various aircraft parts under different environmental conditions. This ensures that the entire test process remains rapid and accurate, contributing to the overall safety and performance of the aircraft.

User Evaluation and Decision-Making

User evaluations and success stories demonstrate the benefits of modular design in industrial instrumentation and metering. One case study from a leading industrial electronics firm shows that by adopting modular systems, they were able to reduce the time required to bring a new product to market by 25% while maintaining high standards of precision. The ease of integrating new sensor technologies and signal processing algorithms through modular components significantly boosted the efficiency of their development process.

Another example highlights the cost-effectiveness of modular design. A manufacturing company that switched from monolithic to modular systems reported a 40% reduction in maintenance costs over the first two years. This was largely due to the ease of replacing single modules rather than entire systems.

Conclusion

The modular design approach in customized development for instruments and meters offers a compelling solution to the dynamic and precise requirements of modern industrial processes. With its adaptability, cost-efficiency, and robust performance, modular design is proving to be a transformative technology in the field of industrial instrumentation. As industrial automation continues to advance, the benefits of modular design are likely to become increasingly apparent, driving further innovation and improvement in the industry.