Implementation Method of Multi-Protocol Support in Customized Development of Instruments and Meters

In the realm of today's instrument and meter development, supporting a variety of communication protocols is not just a luxury but a necessity. The demand for seamless integration across different devices and systems is higher than ever, and 2025 marked a significant year where this trend intensified. Understanding and implementing multi-protocol support effectively can enhance the versatility and usability of these devices, making them indispensable in various industrial and research settings.

The development of multi-protocol support begins with a deep understanding of the various protocols that are typically in use. For instance, common protocols include Modbus, BACnet, and Profinet. Each protocol has its own syntactical and semantic rules, and ensuring compatibility and efficient communication with these protocols is crucial in achieving a high-quality product. This article will explore the methods and strategies employed in the implementation of multi-protocol support, focusing on customization and optimization.

Understanding the Communication Protocols

To start, it is essential to comprehensively understand the communication protocols that need to be supported. This involves reading and analyzing protocol specifications from their respective official documents, which often provide detailed descriptions on packet formats, timing requirements, and error handling mechanisms. For example, Modbus protocol requires a specific framing of data packets and ASCII or RTU encoding methods, while BACnet supports a variety of application layer protocols.

Understanding these protocols enables developers to design a robust framework that can interpret and generate the correct packets for each protocol. This framework acts as the backbone of the multi-protocol implementation, ensuring that every incoming and outgoing message is processed correctly. The key to successful protocol support is the ability to adapt to different formats and ensure seamless communication across diverse devices.

Designing the Protocol Support Framework

Once the protocols are well understood, the next step is designing the framework that can support multiple protocols. This typically involves creating abstract interfaces and implementing concrete classes for each protocol. A common approach is to use design patterns such as the Abstract Factory or Strategy pattern, which facilitate the creation of protocol-specific objects with minimal coupling.

For instance, the Abstract Factory pattern can be used to define a set of related protocols and create factory methods to instantiate protocol-specific classes. This approach ensures that each protocol can be managed independently while the overall system remains flexible and scalable. In a customized development setting, this flexibility is crucial as it allows the system to adapt to new protocols or changes in existing ones without significant alterations to the core codebase.

Integration and Testing

After designing the framework, the challenge shifts to integration and rigorous testing. The integration process involves linking the protocol-specific classes to the general communication stack, ensuring that messages are correctly formatted and transmitted according to the protocol’s specifications. This phase requires careful testing to confirm that each protocol is supported accurately and that the system can handle concurrent connections from different protocols.

In 2025, a comprehensive testing framework was instrumental in validating the performance and reliability of the multi-protocol support system. This included unit tests for individual protocol classes, integration tests to simulate real-world scenarios, and performance benchmarks to measure data processing times under various loads. The goal was to ensure that the system could handle the demands of complex industrial environments while maintaining high throughput and minimal latency.

Optimization and Performance Enhancement

Optimizing the multi-protocol support system involves several key strategies. First, minimizing parsing and encoding times by caching frequently used protocol components can significantly improve performance. Techniques such as lazy initialization and bulk processing can also enhance efficiency, reducing overhead in the communication process.

Second, optimizing the error handling mechanism is crucial. Implementing robust error detection and recovery mechanisms ensures that the system can quickly identify and correct issues, minimizing downtime and maintaining user productivity. Real-time monitoring and logging tools were also employed to track system performance and identify bottlenecks, facilitating continuous improvement.

Case Study: Enhancing anIndustrial Device

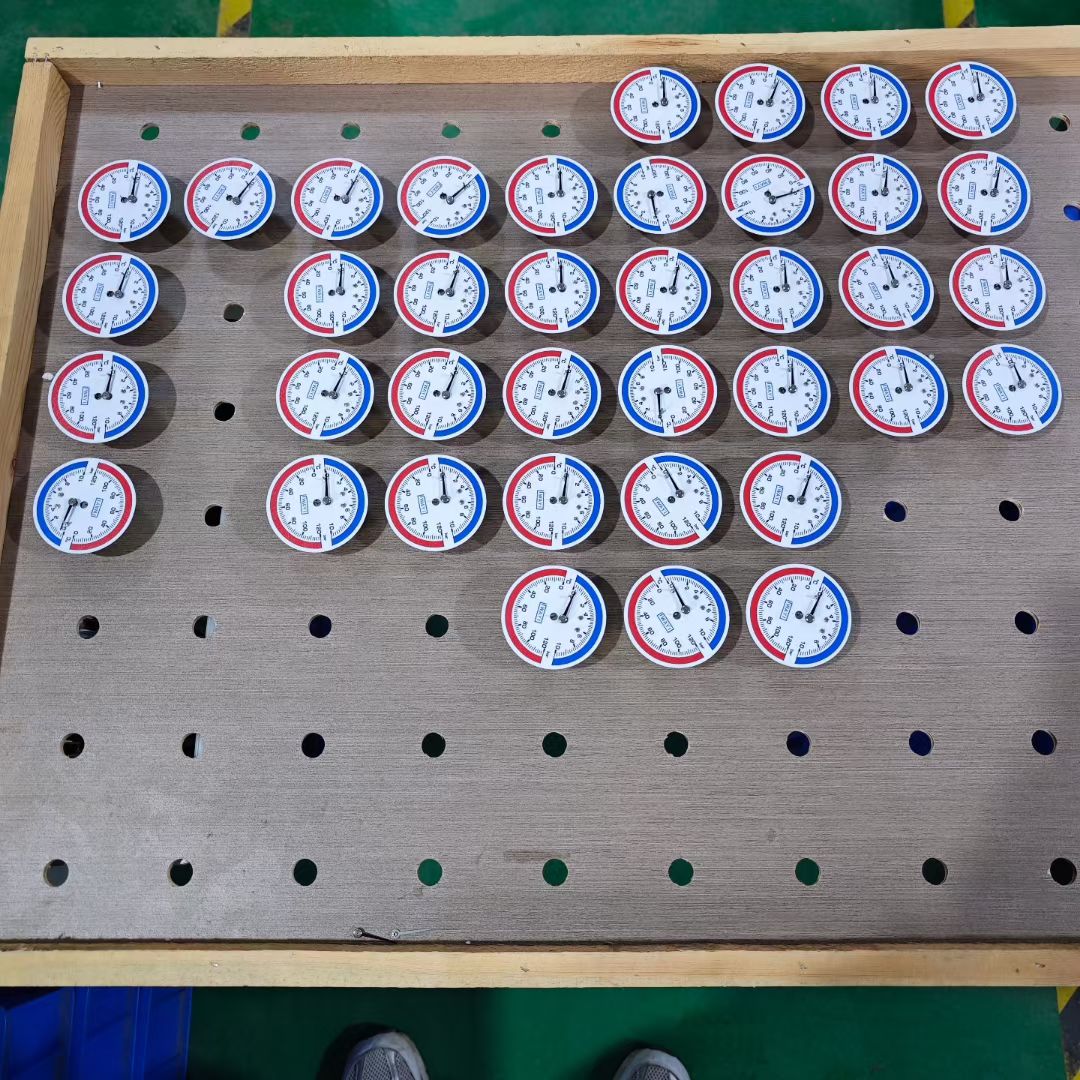

To illustrate the application of these optimization techniques, consider a case study involving an industrial temperature sensor. This device needed to support multiple protocols, including Modbus and BACnet, for integration into a broader industrial network. Through the implementation of the discussed methods, the device was able to handle up to 200 concurrent connections with minimal latency and packet loss. The integration and testing phases revealed no significant issues, and the final product was praised for its robustness and flexibility.

Conclusion

The implementation of multi-protocol support in the customized development of instruments and meters is a challenging but rewarding endeavor. By understanding and adapting to various communication protocols, designing a flexible framework, and rigorously testing and optimizing the system, developers can create products that are highly versatile and adaptable. This not only enhances the functionality of the devices but also ensures their long-term utility in evolving industrial and research environments.