Anti Corrosion Design Standards and Implementation of Customized Instruments and Meters

Designing and implementing anti-corrosion measures for specialized instruments and meters in industrial environments is a critical process that ensures both safety and operational efficiency. This process involves adhering to specific standards designed to combat corrosion, and implementing these standards in a manner that meets the unique requirements of each application. The standards and guidelines for anti-corrosion design are aimed at reducing the risks associated with equipment malfunction due to corrosion. This article will delve into the outlined standards and the step-by-step process of implementing them, showcasing practical examples to guide readers in mastering the necessary techniques.

Understanding Anti-Corrosion Standards and Guidelines

The first step in ensuring that your customized instruments and meters are protected against corrosion is to familiarize yourself with the relevant standards and guidelines. In 2025, the commonly recognized standards include the NACE (National Association of Corrosion Engineers) suite of standards, such as NACE SP0138 "Performance Specification for Electrochemical Corrosion Protection of Nonferrous Metal and Aluminum Alloys in Defense Marine/Marine Non-Defense Atmospheric Environments." These standards define the requirements for various materials and coatings used in anti-corrosion measures.

In addition to these, industry-specific standards such as ASME B31.3 "Pipeline Transportation of Liquids and Gases at Operating Pressures Greater Than or Equal to 10 psig" provide further guidance on what is considered safe and effective in industrial settings. These guidelines are particularly useful in determining the appropriate level of corrosion protection for different types of meters and instruments based on the operating conditions they will face.

Design Flow and Critical Design Considerations

Identifying the Application Environment

The first critical step in designing anti-corrosion measures is understanding the application environment. Factors such as the presence of moisture, salt spray, and other corrosive elements must be taken into account. For instance, marine environments pose unique challenges due to the constant exposure to saltwater, whereas industrial environments with corrosive chemicals can require very different solutions.

Material Selection

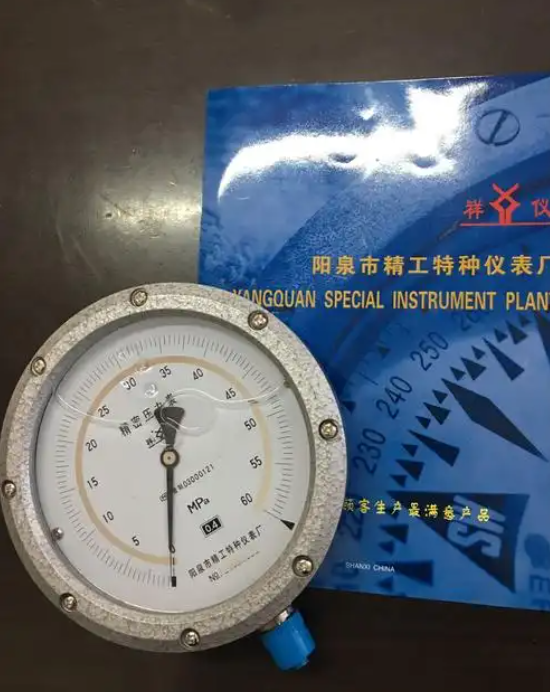

Based on the identified environment, the next step involves selecting appropriate materials that are less prone to corrosion. Common choices include stainless steel, titanium, and certain grades of plastics like PEEK. These materials have been shown to resist corrosion effectively in various environments. For instance, stainless steel is favored in marine settings due to its high resistance to saltwater and chloride ions.

Proper Coating Techniques

Coating is another essential part of the anti-corrosion strategy. A wide variety of coatings, including epoxy,(dictionary missing term: methyldiglycidyl ether) (MDGE) based coatings, and organic-inorganic hybrids, can provide excellent protection against corrosion. It is crucial to apply the coating correctly to ensure maximum effectiveness. For example, electroplating can be used for thin, uniform coatings, while wet-spray methods can provide a bulkier but still protective layer.

Implementation and Quality Assurance

Tools and Instruments

Proper tools are necessary to ensure the effective implementation of anti-corrosion measures. For example, using appropriate brushes and spray equipment can significantly impact the application quality. Additionally, adherence to industry practices for testing the curing and adhesion of coatings is essential to ensure long-term protection.

Quality Control and Testing

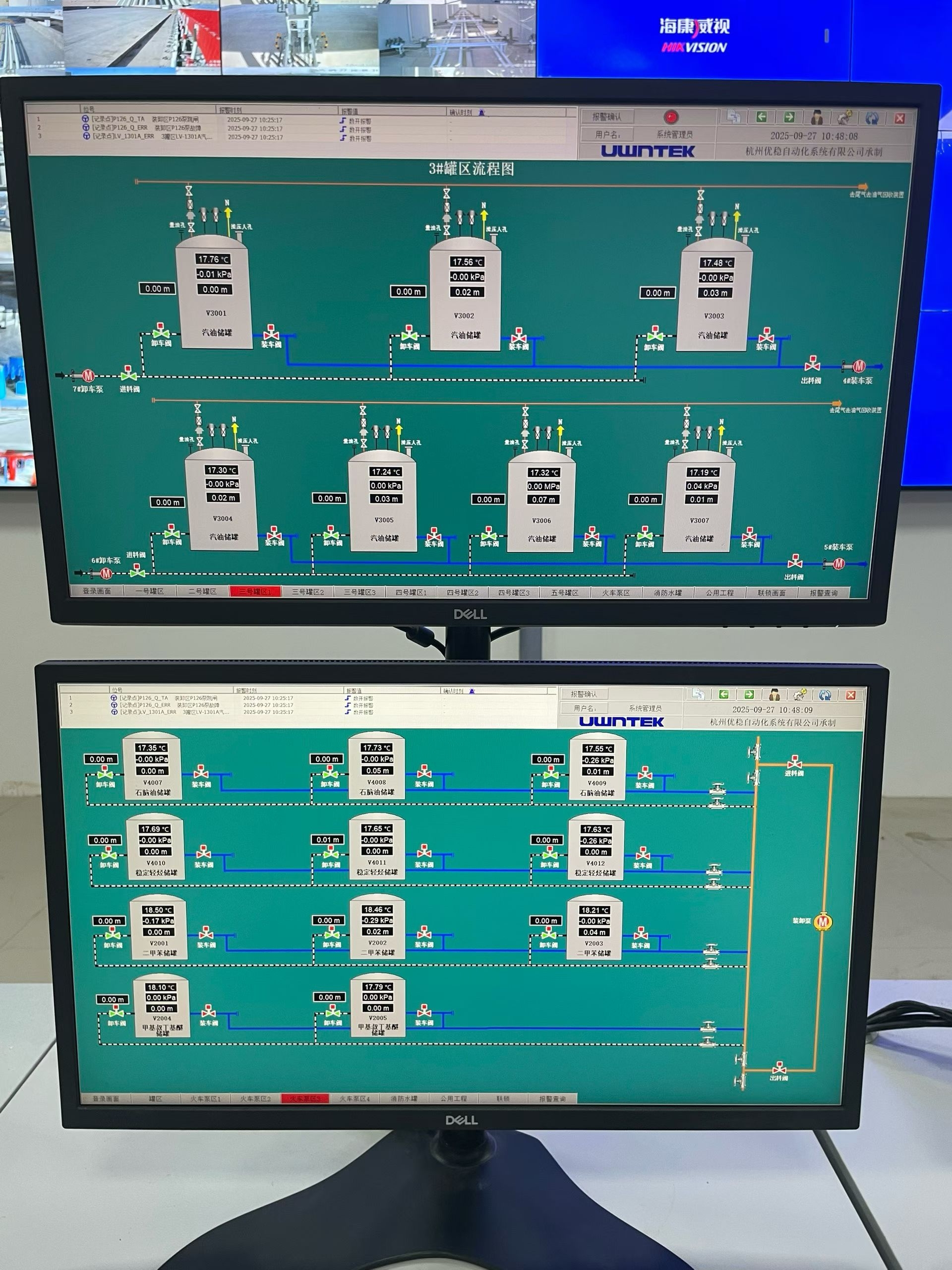

Quality control and testing are vital components of the implementation process. Regular inspections and tests can help identify any early signs of corrosion. Non-destructive testing (NDT) methods such as X-ray radiography, ultrasonic testing, and visual inspection can be employed to monitor the integrity of the instruments and meters over time.

Case Example: Marine Instrumentation

Let's consider a case example: a marine instrumentation system that needs to be deployed in a highly corrosive marine environment. The system includes both pressure and temperature sensors, which are critical for monitoring the quality of the cargo aboard a ship. Key steps in design and implementation include selecting stainless steel as the primary material for the sensors and applying a two-part epoxy coating. The coating is applied using a wet-spray method, ensuring an even and thick layer. Regular NDT inspections are conducted at regular intervals to ensure the integrity of the sensors.

Conclusion

In conclusion, the effective implementation of anti-corrosion design standards for customized instruments and meters is not just about following a set of guidelines but also about understanding the specific environments and conditions under which these instruments will operate. By carefully selecting appropriate materials and coatings, and rigorously testing and maintaining the equipment, you can ensure not only the longevity of these instruments but also their continued reliability. Following this detailed, dynamic, and practical approach can help you achieve superior results in anti-corrosion design and implementation.