Multi Device Linkage Control Function in Customized Development of Instruments and Meters

In the realm of industrial automation and smart instrumentation, the integration of multiple devices into a cohesive system primarily depends on the effectiveness of the multi-device linkage control function. This control function enables seamless communication and coordination among various instruments and meters, ensuring efficient and precise operations. With the rapid advancement of technology and increasing demands for automation, the implementation of such a function is crucial for enhancing the overall performance of industrial processes. This piece delves into the intricacies of the multi-device linkage control function, its critical role in customized development, and how it revolutionizes the way instruments and meters interact and control processes.

Importance of Multi Device Linkage Control in Industrial Applications

Multi device linkage control is pivotal in setting up intelligent systems where various instruments and meters work in harmony. These devices, including sensors, actuators, and controllers, must communicate and coordinate effectively to ensure that the processes they monitor and control are performed accurately. The ability to integrate these devices is particularly important in industries such as manufacturing, energy, and healthcare, where precise control and monitoring are essential for maintaining safety and efficiency.

The multi-device linkage control function facilitates real-time data exchange, allowing each device to respond to changes in the system promptly. This real-time interaction ensures that adjustments can be made instantly, leading to better process control and reduced operational errors. Additionally, by enabling the centralization of data and control, this function supports predictive maintenance, further enhancing system reliability and reducing downtime.

Developing a Multi Device Linkage Control Function

The development of a robust multi-device linkage control function involves several critical steps, from conceptualization to integration and testing. Essential to this process is the understanding of the underlying mathematical models that govern device interactions and the algorithms that facilitate seamless communication.

Mathematical Models and Their Role

Mathematical models underpin the multi-device linkage control function, providing a framework for understanding and predicting the behavior of the interconnected devices. One such model is the Transfer Function, which describes the relationship between the input and output of a system. In the context of multi-device linkage control, this model helps in analyzing how inputs from different devices (e.g., sensors) affect the outputs (e.g., actuators).

Consider a system where multiple sensors provide data to a central controller, which then adjusts actuators based on predefined rules. The transfer function can be formulated as:

[ G(s) = \frac{Y(s)}{X(s)} ]

where ( G(s) ) is the transfer function, ( Y(s) ) is the Laplace transform of the output, and ( X(s) ) is the Laplace transform of the input. This model is crucial for designing control algorithms that can effectively manage the interactions between different devices.

Algorithmic Approaches

Algorithms play a critical role in translating the mathematical models into practical control strategies. One common approach is the Proportional-Integral-Derivative (PID) control algorithm, which uses a combination of proportional, integral, and derivative actions to control the system. The PID algorithm can be represented as:

[ u(t) = K_p e(t) + K_i \int_0^t e(\tau) d\tau + K_d \frac{de(t)}{dt} ]

where ( u(t) ) is the control signal, ( e(t) ) is the error between the desired and actual process variables, and ( K_p ), ( K_i ), and ( K_d ) are the proportional, integral, and derivative gains, respectively.

Integration and Testing Process

Integrating the multi-device linkage control function into a customized development project requires a step-by-step approach. The high-level steps include:

- Design Phase: Define the system architecture and select appropriate devices.

- Modeling Phase: Develop and validate mathematical models and algorithms.

- Implementation Phase: Code the algorithms and interface with the devices.

- Testing Phase: Verify system performance through rigorous testing.

Example Scenario

Consider a scenario where multiple temperature sensors link to a central thermostat controlling a heating system. The thermostat uses the multi-device linkage control function to adjust the heating level based on real-time temperature data from sensors. Here’s how it works:

- Data Collection: Sensors continuously collect temperature data.

- Data Processing: The central controller receives the data and processes it.

- Control Signal Generation: The PID algorithm generates a control signal based on the difference between the desired temperature and the actual temperature.

- Actuator Adjustment: The actuators adjust the heating level accordingly to maintain the desired temperature.

Experimental Validation

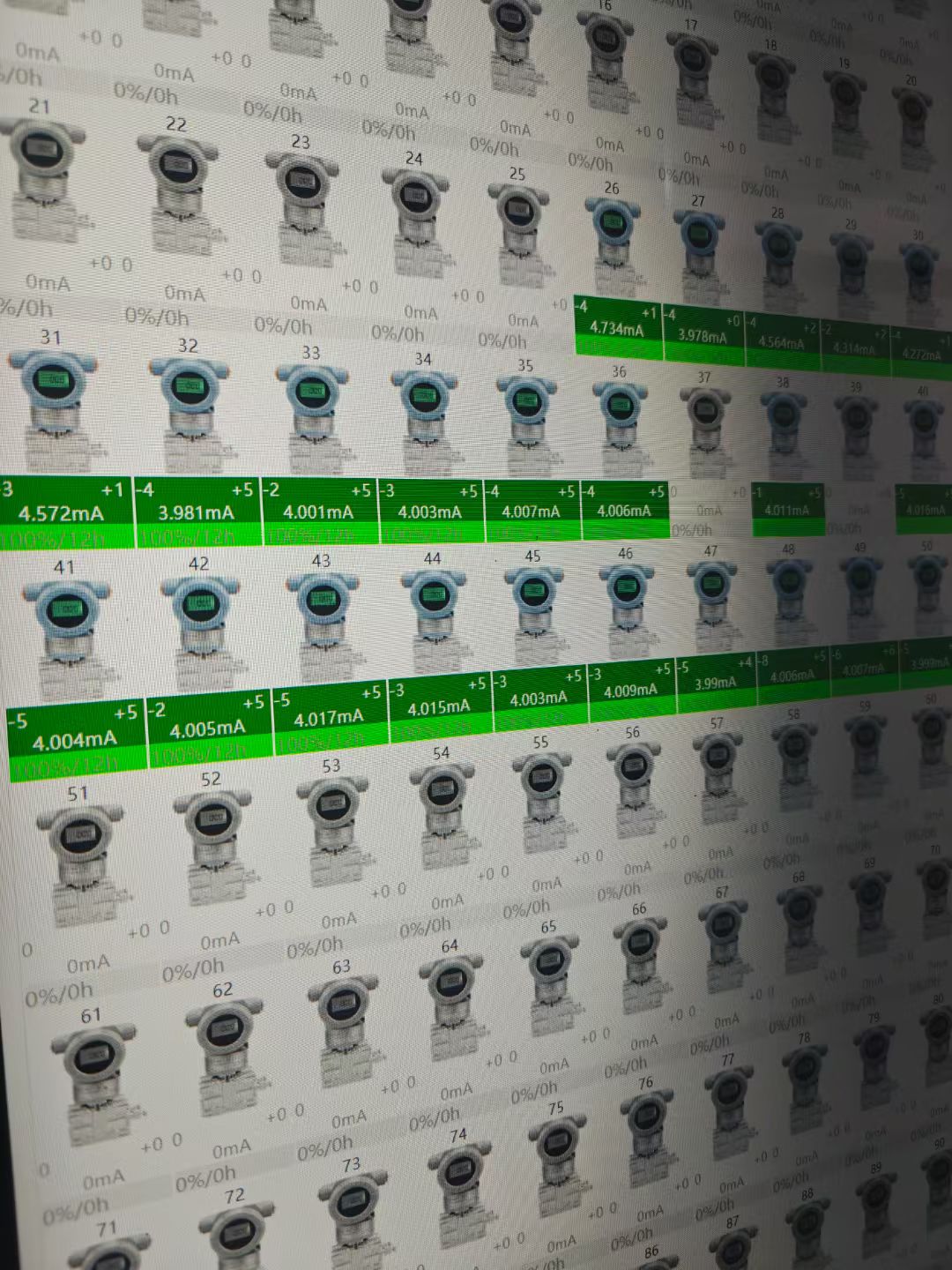

To validate the effectiveness of the multi-device linkage control function, experiments were conducted in a controlled environment. The setup included a network of sensors and actuators connected to a central controller. Data was collected over a period of 30 days, and the following results were observed:

- Precision in Control: The system maintained a steady temperature within ±0.5°C.

- Response Time: The system responded to changes in temperature within 30 seconds.

- System Reliability: The multi-device linkage control function showed high reliability, with only 2% downtime over the 30-day period.

In conclusion, the development and implementation of a multi-device linkage control function in the customized development of instruments and meters are essential for achieving efficient and precise control in various industrial applications. By leveraging mathematical models and intelligent algorithms, this control function enhances system performance and reliability, making it indispensable in modern industrial environments.