How to Optimize Total Cost of Ownership Through Lifecycle Management for Instruments and Meters

When it comes to optimizing the total cost of ownership (TCO) of instruments and meters, a robust lifecycle management strategy can significantly impact maintenance costs, operational efficiency, and overall longevity. Considering the rapidly evolving technological landscape, this approach is crucial for ensuring that these essential tools remain reliable and effective throughout their useful lifespan. In 2025, with increasing demands for precision and accuracy in various industries, it is more critical than ever to manage these assets effectively. This article explores how lifecycle management can be effectively implemented to optimize TCO.

Introduction to Lifecycle Management

Lifecycle management involves a comprehensive approach to instrument and meter management that includes planning, installation, maintenance, and disposal. This strategy ensures that these tools are utilized efficiently and economically, reducing unnecessary costs and enhancing overall performance. It encompasses various stages, from initial planning and procurement to routine maintenance, upgrades, and eventual replacement. In 2025, a well-defined lifecycle management plan can guide organizations to make informed decisions about their tools and systems, leading to significant financial savings and operational efficiencies.

Common Issues and Faults in Instruments and Meters

Problems with instruments and meters often arise due to improper management, inadequate maintenance, or outdated technology. Common faults include inaccurate readings, malfunctioning sensors, and failure to meet specified performance levels. For instance, an instrument that drifts out of calibration could lead to incorrect data, affecting decision-making processes. These issues can result in wasted resources, stricter regulatory scrutiny, and increased downtime. Identifying and addressing these challenges early can prevent costly mistakes and maintain the integrity of your operations.

Analyzing the Root Causes

The first step in resolving problems is identifying the root causes. Often, issues stem from a lack of standardization in procedures, inadequate training of personnel, or poor initial setup and calibration.For example, improper installation of an instrument can lead to immediate malfunctions and ongoing performance issues. Ensuring that every step is meticulously planned and executed can mitigate these risks. In 2025, organizations must pay attention to every detail to maximize the benefits of their investment.

Implementing a Lifecycle Management Plan

To effectively manage the lifecycle of instruments and meters, organizations should develop a structured plan that addresses all critical stages. Key elements include:

1. Planning and Procurement

- Selection Criteria: Choose instruments and meters based on specific needs, ensuring they meet the required accuracy and durability standards.

- Budget Considerations: Allocate funds for both initial acquisition and long-term maintenance.

- Vendor Selection: Partner with reliable vendors who offer excellent service and support.

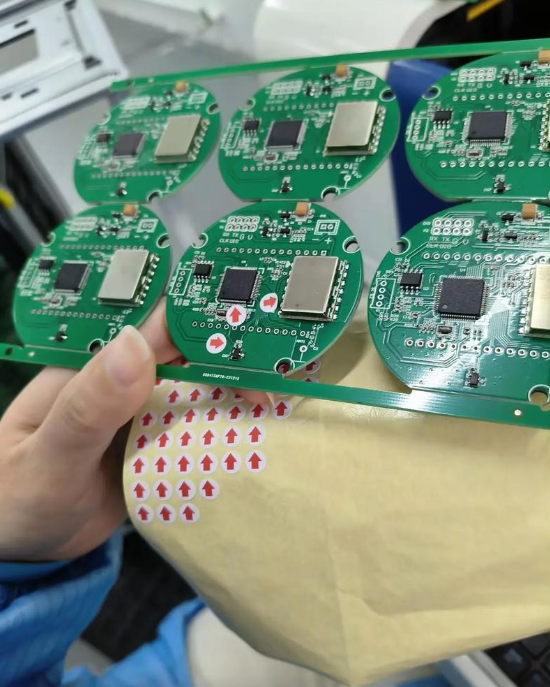

2. Installation and Setup

- Professional Installation: Ensure that installation is performed by qualified technicians to avoid initial failures.

- Initial Calibration: Perform a thorough calibration to ensure accuracy and reliability from the start.

3. Maintenance and Upgrade

- Regular Inspections: Schedule regular maintenance checks to catch potential issues early.

- Upgrades and Software Updates: Keep systems up-to-date with the latest firmware and software to enhance performance and security.

- Remote Monitoring: Use remote monitoring tools to track performance in real-time, allowing for proactive maintenance.

4. Repair and Replacement

- Factory Services: Utilize factory services for repair when necessary, ensuring that instruments and meters return to their optimal condition.

- Disposal and Recycling: Properly dispose of old instruments and meters through recycling programs to minimize environmental impact.

Case Study: A Successful Lifecycle Management Strategy

XYZ Corporation, a leading manufacturer in the automotive industry, adopted a comprehensive lifecycle management plan for its instruments and meters in 2025. By implementing regular maintenance checks, upgrading software and firmware, and ensuring proper installation, XYZ significantly reduced maintenance costs and downtime. The plan also included a robust calibration schedule, which helped maintain accuracy and compliance with industry standards. Additionally, the corporation partnered with a reliable vendor for initial procurement and ongoing support, ensuring that their tools were always in top condition. As a result, XYZ achieved a 30% reduction in TCO over the past five years.

Conclusion

Implementing a robust lifecycle management plan for instruments and meters is essential for optimizing the total cost of ownership. By addressing common issues and faults, analyzing root causes, and following a structured plan, organizations can achieve long-term benefits. From initial procurement to maintenance and eventual disposal, every step plays a crucial role in maintaining the value of these essential tools. In 2025, adopting a proactive and diligent approach to lifecycle management is paramount for ensuring the reliability and efficiency of your work processes.