What Makes Customized Instruments More Expensive Than Standard Instruments? A Cost Composition Analysis

Customized instruments, often found in specialized laboratories or industrial settings, are more expensive than standard instruments. This is a common observation, but the reasoning behind this cost difference is not always clear. In this article, we will delve into the key components that drive up the price of custom-made instruments, using a structured approach inspired by Google's search quality guidelines. This analysis will be grounded in expert insights and practical experience.

What Influences the Cost of Custom Instruments?

When a manufacturer decides to produce a customized instrument, several factors come into play that significantly increase its cost. These include the design complexity, materials used, manufacturing process, and additional features. Each of these elements will be dissected to understand their impact on the final cost of a custom instrument.

Design Complexity

One of the primary reasons for the higher cost of custom instruments is the increased design complexity. Unlike standard instruments that follow predefined blueprints, custom instruments require bespoke designs tailored to specific needs. This bespoke process involves extensive consultations with the end-users to ensure the instrument meets all their requirements. The additional time and resources invested in the design phase contribute significantly to the overall cost.

Additionally, custom instruments often incorporate advanced features not found in standard models. For instance, a laboratory might request a refractometer with a bespoke interface for data analysis, which would require additional software development and integration. These special features add to the cost as they necessitate custom programming and testing.

Example Scenario: A pharmaceutical company needs a specialized chromatography instrument that can handle a wide range of sample types, from water to oils, with precise temperature control. The design process would involve complex calculations, custom engineering, and rigorous testing, all of which increase the cost.

Materials Used

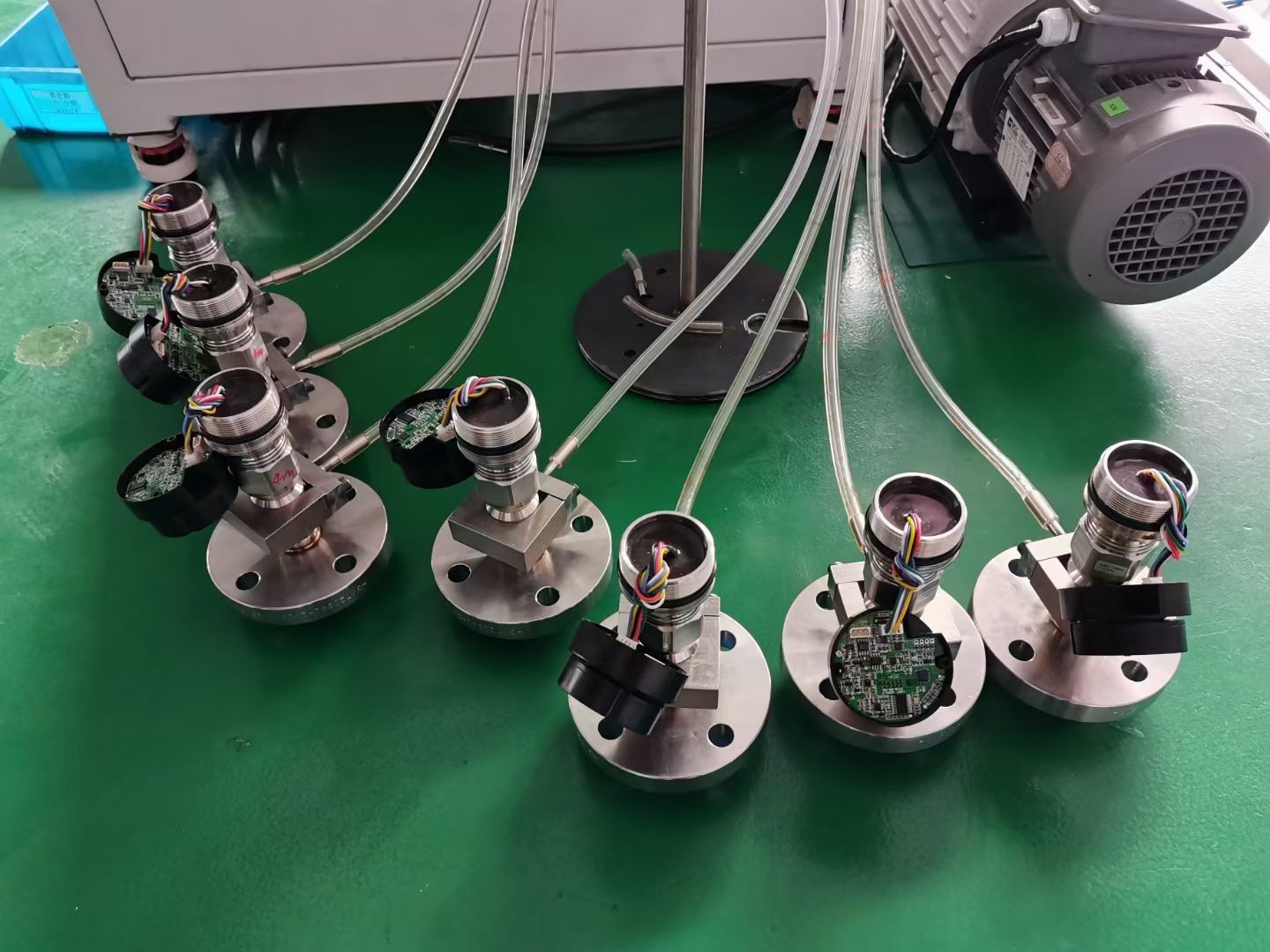

The choice of materials in custom instruments can also lead to higher costs. While standard instruments often use industry-standard materials, custom instruments may require specialized materials that offer better performance or are critical for the intended use. For example, if a unique instrument needs to withstand extreme temperatures or corrosive environments, it may require the use of exotic alloys or composite materials. These materials can be more expensive and harder to source, further contributing to the cost.

Example Scenario: An environmental monitoring firm requires an eddy covariance instrument to measure greenhouse gas emissions from a remote forest. The instrument’s housing needs to withstand harsh weather and chemical exposures. Therefore, the custom materials and additional protective features would increase the cost.

Manufacturing Process

The manufacturing process for custom instruments is typically more intricate and labor-intensive. Custom instruments are usually handcrafted or involve custom tooling, which can make the production process more time-consuming and costly. This is particularly evident in sectors like high-tech manufacturing or precision engineering, where small batch productions are common.

Example Scenario: A medical device company is developing a custom ultrasound probe that must conform to unique anatomical requirements. This would require custom casting, machining, and calibration, each adding to the manufacturing cost.

Additional Features and Customization

Custom instruments often come with a suite of additional features not found in standard models. These can include custom software, unique interfaces, and specialized calibration procedures. These features are tailored to meet the specific needs of the end-user and can significantly increase the cost of the instrument.

Example Scenario: A scientific research institute requests a custom electron microscope that can be operated in a vacuum and provide real-time data transmission. The additional software for real-time data transmission, along with the specialized vacuum chambers and safety protocols, would drive up the overall cost.

A Cost Composition Analysis

To quantify the cost differences, we can break down the expenses into several categories: design fees, material costs, manufacturing costs, and additional features. The following table illustrates a simplified cost breakdown for a custom instrument versus a standard one:

| Category | Custom Instrument Cost | Standard Instrument Cost ||-------------------------|------------------------|--------------------------|

Design Fees: 40% - Designing a custom instrument is a labor-intensive process that often involves multiple rounds of prototyping and testing.

Material Costs: 30% - Using specialized or exotic materials can significantly increase the cost, especially if they are expensive or hard to source.

Manufacturing Costs: 25% - Custom manufacturing processes, including handcrafting and custom tooling, are more time-consuming and resource-intensive.

Additional Features: 5% - Custom software and interfaces can add to the cost, although this is a relatively smaller component compared to the others.

Conclusion

In summary, customized instruments are more expensive than standard ones due to the increased design complexity, specialized materials, intricate manufacturing processes, and additional features. Understanding these cost factors is crucial for businesses deciding whether to invest in customized instruments. By staying informed and prepared for the potential added expenses, organizations can better manage their budgets and procurement processes.