How to Evaluate the Qualifications of Suppliers When Purchasing Instruments and Meters in 2025

In the ever-evolving market of instruments and meters, choosing the right supplier can significantly impact the quality and efficiency of your operations. Whether you are in the industrial, scientific, or medical sectors, reliable and accurate instruments are crucial for performance and safety. In 2025, evaluating the qualifications of suppliers becomes an imperative step to ensure you receive the best possible equipment. This article will guide you through the process of identifying competent suppliers by delving into the necessary documentation, understanding industry standards, and exploring practical examples.

Documentation and Compliance

When purchasing instruments and meters, the first step involves evaluating the supplier’s credentials. Look for formal documentation that outlines the supplier’s ability to meet regulatory and quality standards. In 2025, suppliers should be certified by recognized bodies such as the International Organization for Standardization (ISO) and comply with quality management systems.

ISO 9001 Certification is a widely recognized standard for quality management systems. Suppliers should have evidence of this certification, which ensures they adhere to strict quality practices and procedures. Additionally, certifications such as ISO 17025 for laboratory accreditation, CE marks for Europe, and FCC for the United States, can also verify the supplier’s compliance with local and international standards.

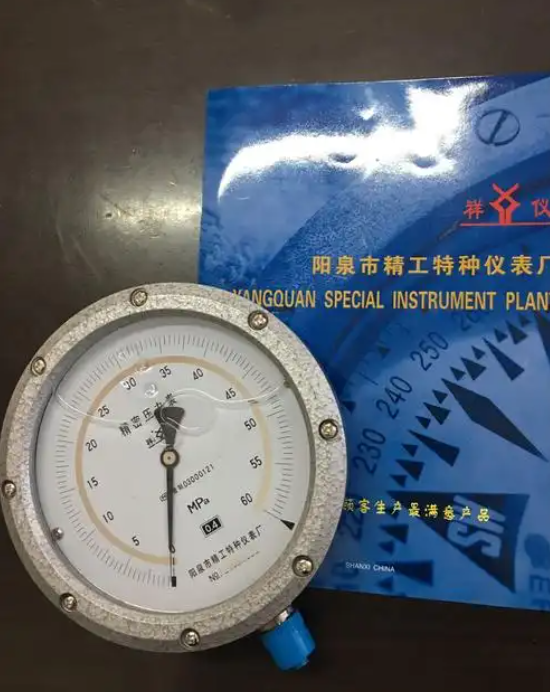

Suppliers should provide a comprehensive product history. This includes documentation on product development, testing, calibration, and maintenance. Understanding the supplier’s quality control processes and how they ensure consistency and accuracy in their products is essential.

Understanding Industry Standards

Industry standards play a critical role in ensuring the reliability and performance of instruments and meters. Depending on your specific application, understanding relevant industry standards is crucial. For example:

- IEEE (Institute of Electrical and Electronics Engineers) standards are vital for electronic and electrical components.

- ASTM (American Society for Testing and Materials) standards are necessary for materials testing and analysis.

- ISO standards like ISO 14644 for cleanrooms are important in medical and high-tech environments.

Suppliers should be familiar with and adhere to the relevant industry standards. They should also be able to provide details on how their products comply with these standards. This includes test reports, third-party certifications, and audit results.

Practical Examples and Supplier Evaluations

Let’s explore a practical example of how to evaluate a supplier:

Supplier A claims to provide the latest and most advanced measurement equipment for the aerospace industry. To evaluate this claim, we would start by reviewing their ISO 9001 and ISO 17025 certifications. We would then request detailed product histories and test reports to ensure that their instruments meet the strict environmental and operational requirements of the aerospace industry.

A key part of the evaluation process involves firsthand inspection of the supplier’s facilities. Supplier A invited us to visit their manufacturing plant, and during our inspection, we observed stringent quality control measures, including regular calibration checks and traceability documentation. The staff demonstrated their expertise and knowledge of the products, which provided us with confidence in their capabilities.

Furthermore, we sought feedback from other customers who had used Supplier A’s instruments. Positive reviews indicated that the supplier provided consistent, reliable products that met industry standards and performed well under various conditions. This feedback, along with the supplier’s certifications and documentation, helped us make an informed decision.

Conclusion

In 2025, the procurement of instruments and meters is a meticulous process that requires thorough evaluation of suppliers. By focusing on documentation, understanding industry standards, and exploring practical examples, you can ensure that you select the best supplier to meet your needs. Remember, selecting the right supplier not only enhances performance but also guarantees safety and compliance in your operations.