Panorama of the Instrumentation Industry Chain: From Upstream Materials to Downstream Applications

The instrumental industry is experiencing an era of transformation and growth, marked by rapid advancements in technology and increasing demands from diversified sectors. According to a leading industry report published in 2025, the global instrumentation market is projected to grow at a compound annual growth rate (CAGR) of 5.8% over the next five years. This growth can be attributed to the continuous innovations in sensor technologies, the surge in demand from healthcare and automotive industries, and the increasing need for real-time monitoring solutions in various applications. The landscape of the instrumentation industry is becoming more complex and dynamic, with players adapting to these changes to remain competitive.

Building Blocks of the Upstream Materials

At the heart of the instrumentation industry is the upstream materials sector, where critical components such as sensors, electronics, and materials for construction play a pivotal role. 2025 saw significant breakthroughs in the development of new materials like graphene and 3D-printed components, which have enhanced the performance, sensitivity, and reliability of instrumentation devices. These materials are also driving down costs and opening new opportunities for customization and miniaturization. The choice of materials can drastically influence the accuracy, durability, and functionality of instruments, hence the critical importance of this sector.

Processing and Assembly

Moving downstream, the processing and assembly phases are where raw materials are transformed into fully functional instrumentation devices. Automation and robotics have taken center stage, streamlining the manufacturing process and improving quality control. Advanced techniques like automated calibration and rigorous testing ensure that products meet stringent industry standards. The integration of Industry 4.0 technologies, such as Internet of Things (IoT) and artificial intelligence (AI), is enabling more precise and efficient manufacturing processes. These advancements are driving the industry towards higher productivity and better cost-effectiveness.

Downstream Applications: Diversified Demand

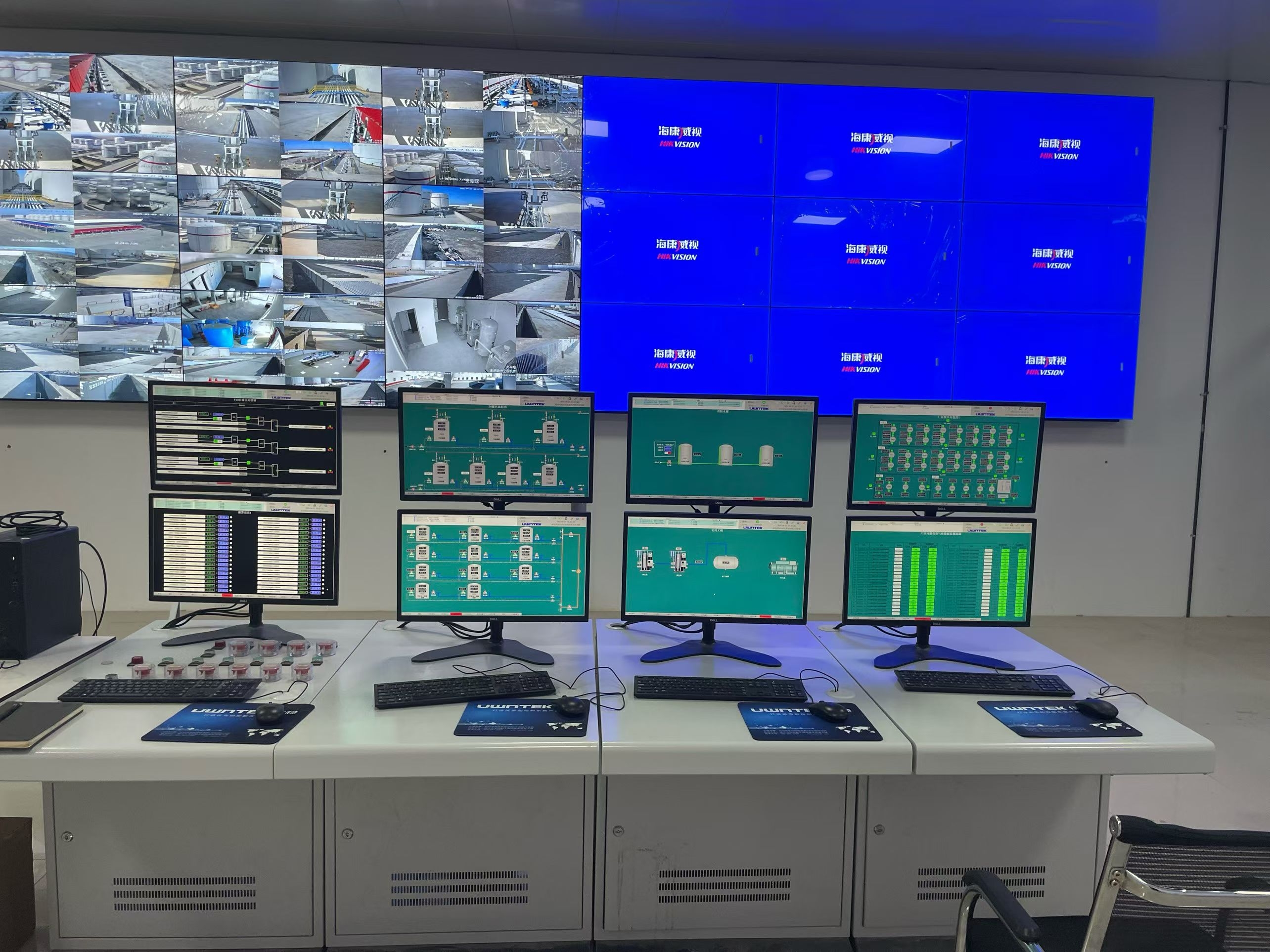

The demand for instrumentation is highly diversified, spanning numerous sectors like healthcare, automotive, manufacturing, and environmental monitoring. In 2025, the healthcare sector emerged as a key driver, with a sharp increase in demand for devices like blood glucose monitors, wearable health trackers, and telemedicine equipment. The automotive industry also witnessed significant growth, owing to the heightened emphasis on safety and real-time diagnostics in vehicles. Manufacturers are now incorporating advanced sensors and monitoring systems to enhance efficiency and reduce maintenance costs. Similarly, environmental monitoring has seen a notable boost, with the increasing awareness of climate change and the need for sustainable solutions.

Future Directions and Expert Predictions

Given the prevailing trends, experts predict that the instrumentation industry will continue to evolve at a fast pace. The integration of advanced sensor technologies such as nanosensors and smart materials will enable more precise and accurate data collection. Machine learning algorithms will play a crucial role in optimizing performance and enhancing reliability. Additionally, the trend towards green and sustainable practices is expected to influence the development of eco-friendly materials and energy-efficient devices.

Engaging the Reader: Future Trends and Your Role

To better understand the future of the instrumentation industry, it is essential to engage with the latest developments and trends. Recent readers have shown a keen interest in exploring how emerging technologies can be applied to real-world challenges. For instance, many are curious about the role of IoT in predictive maintenance and how AI can enhance data analysis and decision-making in various sectors.

As a survey respondent mentioned, "The integration of AI in real-time monitoring systems could revolutionize the way we handle data in industrial settings." Another reader noted, "We need to focus more on sustainable materials to ensure that our instrumentation devices contribute positively to the environment."

By staying informed and involving yourself in these discussions, you can contribute valuable insights and innovative ideas to shape the future of the instrumentation industry. Whether you are a technology enthusiast, an industry professional, or a student, your input can help us navigate the complex dynamics of this evolving field.

In conclusion, the instrumentation industry is poised for remarkable growth and transformation, driven by continuous technological advancements and diverse industry demands. By understanding the upstream materials, processing and assembly phases, and the wide array of downstream applications, we can better anticipate and adapt to future trends.