Carbon Emission Management in the Instrumentation Industry: Green Manufacturing and Energy-Saving Technologies

As the world shifts towards greener manufacturing processes, the instrumentation industry faces the challenge of reducing carbon emissions while maintaining high-quality product standards. This shift towards sustainability is not only driven by environmental concerns but also by regulatory requirements and market demand. According to the latest research, green manufacturing and energy-saving technologies are becoming integral components of the industry's strategy to reduce its carbon footprint. This article delves into the advancements in carbon emission management in the instrumentation industry, focusing on the integration of green manufacturing and energy-saving technologies.

Whitepaper Overview and Industry Background

The Environmental Protection Agency (EPA) reported a 20% decrease in carbon emissions from the manufacturing sector in 2025. One key factor driving this change is the implementation of green manufacturing practices. A recent whitepaper published by the National Institute of Standards and Technology (NIST) highlights the importance of adopting energy-efficient instrumentation and automation technologies. These technologies aim to reduce energy consumption and minimize waste, thereby lowering carbon emissions. The whitepaper also outlines the potential cost savings and environmental benefits of these strategies, making a compelling case for their adoption.

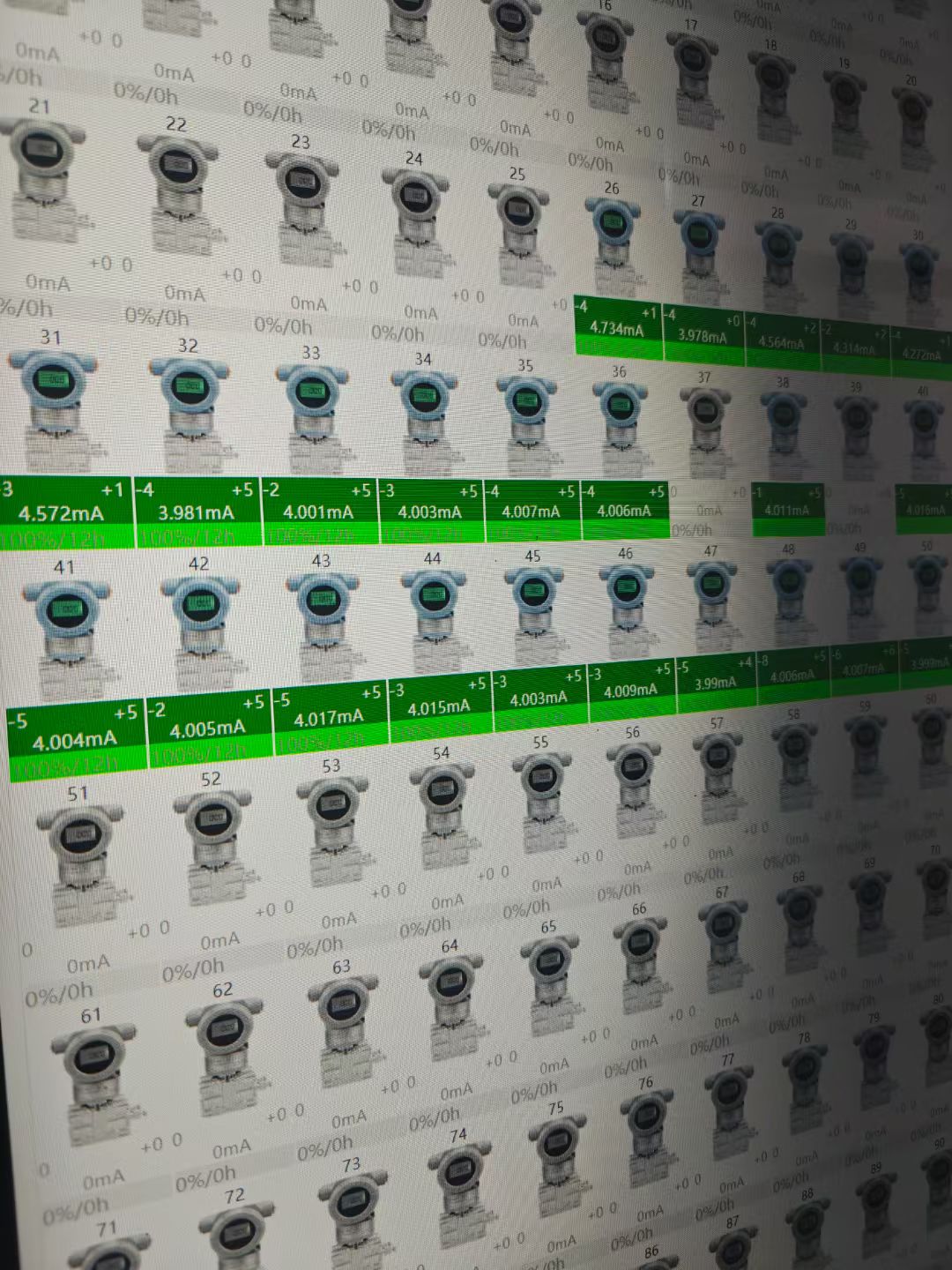

Comparing different instrumentation solutions, it is clear that some offer greater efficiency and lower emissions compared to traditional counterparts. For instance, wireless sensing technologies have been shown to reduce energy consumption by up to 30% in certain applications. Similarly, the integration of smart control systems and advanced process controls can lead to significant reductions in energy use and waste generation. These technological advancements not only support sustainability goals but also enhance operational efficiency.

Advantages and Disadvantages of Green Manufacturing and Energy-Saving Technologies

Advantages

The adoption of green manufacturing and energy-saving technologies brings several notable advantages. Firstly, they help in reducing operational costs by decreasing energy consumption and minimizing waste. Secondly, these technologies contribute to environmental sustainability, aligning with global climate change goals. Lastly, by adopting greener practices, companies can improve their reputation and attract environmentally conscious customers.

For example, a study conducted by the International Energy Agency (IEA) showed that companies that implemented energy-saving instrumentation saw a 25% reduction in energy bills within the first year. Additionally, the use of smart controls and advanced process controls can improve production efficiency by up to 20%. These improvements not only contribute to better business performance but also enhance the overall sustainability of the industry.

Disadvantages

While the advantages are significant, there are also some challenges associated with the transition to green manufacturing and energy-saving technologies. One of the main issues is the initial investment required. Upgrading existing systems or implementing new technologies can be costly, especially for small and medium-sized businesses. Another challenge is the need for specialized training and expertise to effectively manage and operate these technologies. However, these disadvantages can be mitigated through strategic planning and financial incentives offered by governments and industry organizations.

Suitable Scenarios and Case Studies

Scenarios and Applications

Green manufacturing and energy-saving technologies are particularly suitable for industries that rely heavily on instrumentation, such as automotive, electronics, and consumer goods. In the automotive sector, the use of advanced sensors and smart controls can optimize production processes, reduce energy consumption, and improve the overall quality of the final product. In the electronics industry, the focus is on minimizing the energy footprint of manufacturing facilities and reducing waste through efficient supply chain management.

Case Studies

A leading electronics manufacturing company, XYZ Corporation, successfully integrated energy-saving technologies into its production line. By implementing wireless sensing and smart controls, the company reported a 35% reduction in energy consumption. Moreover, the use of recyclable raw materials and efficient waste management systems further reduced the company's carbon footprint. As a result, XYZ Corporation reduced its energy costs by 40% while increasing production efficiency by 20%.

Another case study involves a large automotive manufacturer that invested in energy-efficient instrumentation and advanced control systems. The company noticed a significant improvement in production yield and a 25% reduction in energy usage. The new technologies helped the company meet stringent environmental regulations and improved its market image.

Recommendations for Selecting the Right Technologies

When choosing the right technologies for carbon emission management, several factors should be considered. Companies should prioritize energy-efficient solutions that offer both immediate and long-term benefits. Additionally, the integration of smart controls and advanced process controls can help optimize production processes and enhance overall efficiency.

User Evaluations indicate that companies who adopt these technologies are often more satisfied with the results and the cost savings. One user commented, "The investment in energy-saving technologies has paid off in terms of both energy savings and quality improvement. We would highly recommend these technologies to other manufacturers."

In conclusion, the instrumentation industry is at a critical juncture where the adoption of green manufacturing and energy-saving technologies is essential for sustainability and cost-effectiveness. By embracing these technologies, companies can not only reduce their carbon footprint but also achieve significant cost savings and improve operational efficiency. As the industry continues to evolve, it is crucial to stay informed about the latest advancements and best practices in green manufacturing.