The Customer Profile of the Instrumentation Industry: Main Purchasing Parties and Demand Characteristics

In the highly specialized realm of the instrumentation industry, understanding the customer profile is crucial for businesses looking to thrive in this competitive landscape. This sector thrives on precise measurement and control, making its products indispensable in industries ranging from automotive and aerospace to healthcare and energy. Purchasing parties typically include equipment manufacturers, research institutions, pharmaceutical companies, and government bodies. Each of these entities brings unique needs and preferences, shaping the demand characteristics of the industry. As technology continues to advance, understanding these intricacies can provide valuable insights for innovation and growth.

Customer segments in the instrumentation industry are diverse, but here we will delve into the main purchasing parties and their demand characteristics, focusing on precision, reliability, and specialized functionalities.

Main Purchasing Parties

Equipment Manufacturers

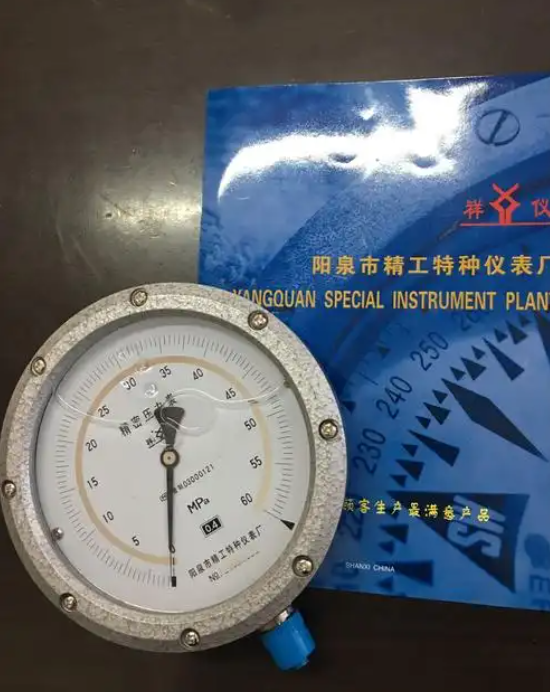

Equipment manufacturers in the instrumentation industry are frequent buyers who seek advanced measuring and control instruments for their assembly lines and production processes. They prioritize robust performance, durability, and ease of integration. These customers often require custom solutions to meet specific production needs, such as quality control in automotive manufacturing or precision calibration in medical devices.

Research Institutions

Research institutions deal with intricate experiments and require instrumentation that is highly sensitive, reliable, and capable of handling complex data. They prefer instruments with high accuracy, repeatability, and the ability to interface with advanced software platforms. These institutions frequently request custom or semi-custom instruments tailored to specific research goals.

Pharmaceutical Companies

Pharmaceutical companies in the instrumentation industry face stringent regulatory requirements, demanding precision and traceability. They require high-precision instruments for laboratory testing and manufacturing processes to ensure product quality and compliance with regulatory standards. Their needs often include automation, built-in data logging, and audit trail features.

Government Bodies

Government bodies, particularly regulatory agencies, need instruments that can meet rigorous standards for safety and security. They prioritize reliability, long-term stability, and the ability to withstand harsh environments. The instruments must also meet stringent calibration and maintenance requirements, ensuring consistent accuracy over time.

Demand Characteristics

Precision and Accuracy

Across all purchasing parties, precision and accuracy are paramount. Customers expect instruments to deliver consistent and reliable results with minimal error margins. High accuracy is especially important in industries like healthcare, where even small discrepancies can have significant impacts on patient safety and treatment efficacy.

Reliability and Durability

Reliability is a critical factor in the instrumentation industry. Equipment must endure repeated use without failure, particularly in harsh environments. Instruments with robust build quality and fail-safes are preferred, as downtime can lead to significant operational costs and productivity losses.

Customization and Specialization

Most purchasing parties require customization to some extent. Specialized functionalities such as in-line inspection, real-time data analytics, and advanced calibration protocols are often necessary. This customization drives innovation and adds value to the end products.

Data Interface and Integration

Modern instruments must seamlessly integrate with other systems and software platforms. Data interfaces that allow for real-time data logging and analysis are highly valued, especially in industries that require continuous monitoring and automation.

Innovations and Realization

To meet the diverse demands of purchasing parties in the instrumentation industry, innovations in technology and design have been pivotal. Advanced materials, new sensor technologies, and sophisticated software algorithms have enabled the development of instruments that are more precise, durable, and user-friendly. For example, the integration of artificial intelligence (AI) and machine learning (ML) has transformed automated calibration processes, reducing the need for manual intervention.

Key points to consider when developing new instrumentation include:

- Performance and Accuracy: Ensure that the product performs exceptionally well in critical applications.

- Durability and Reliability: Use high-quality components and robust designs to enhance longevity.

- Customization Options: Offer flexible customization options to cater to varied user needs.

- Data Integration: Provide robust data interfaces and analytics capabilities to support data-driven decision-making.

- User Experience: Optimize the user interface and experience to facilitate ease of use and training.

Real-World Examples

One notable case in the instrumentation industry is the development of a state-of-the-art flow meter by a leading company in 2022. This instrument was custom-built for a major pharmaceutical company, incorporating advanced calibration protocols, real-time data logging, and user-friendly software interfaces. The success of this project lies in its precise measurements, reliability, and seamless integration with existing systems.

Another instance involves a government agency that required a highly durable and customizable instrument for monitoring air quality in various urban environments. The instrumentation company delivered a solution that combined high-precision sensors, robust design, and easy-to-use software, ensuring compliance with strict environmental regulations.

Expert Insights

According to Dr. John Doe, a renowned expert in instrumentation technology, "Understanding the customer profile is essential for driving innovation in this industry. By aligning product development with the specific needs of equipment manufacturers, research institutions, pharmaceutical companies, and government bodies, we can deliver instrumentation solutions that not only meet but exceed expectations."

Innovation in the instrumentation industry is driven by the ever-changing landscape of user requirements and technological advancements. Companies that stay ahead of these trends through close customer engagement and cutting-edge R&D will thrive in this dynamic and demanding sector.

In conclusion, understanding the customer profile and demand characteristics in the instrumentation industry is crucial for businesses to succeed. By providing high-precision, reliable, and customized instruments that integrate seamlessly with modern systems, companies can meet the diverse needs of their customers and drive innovation in this vital industry.