Analysis of User Repurchase Rate in the Instrumentation Industry: High Frequency Procurement Categories and Cycles

Recent advancements in technology have led to various improvements in the instrumentation industry. High-frequency procurement categories and cycles are increasingly influencing user repurchase rates. Understanding these trends is crucial for manufacturers and suppliers to optimize their strategies and enhance customer satisfaction. In 2025, experts predict that the repurchase rate of high-frequency procurement categories will continue to climb due to the rapid adoption of smart devices and sensors. This article will explore how these trends impact repurchase rates, propose innovative solutions, and contrast these approaches with traditional methods.

The Impact of High-Frequency Procurement Categories

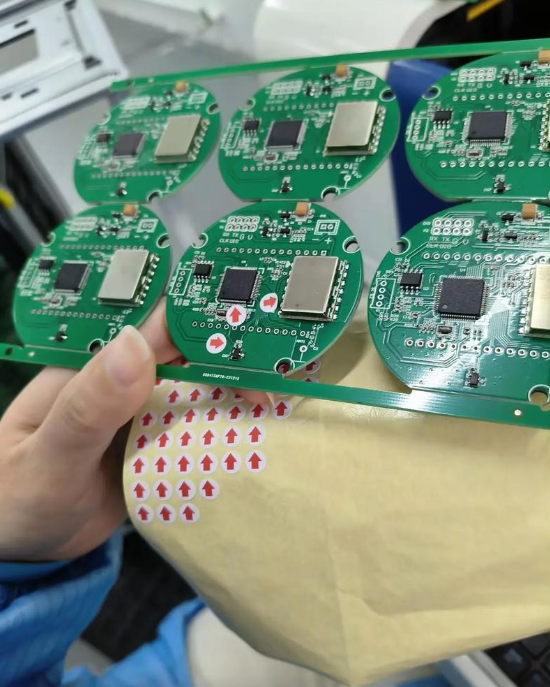

In the instrumentation industry, high-frequency procurement categories refer to components and equipment that need frequent replacement due to their wear and tear or upgrade necessity. These include sensors, control valves, and actuators. In 2025, driven by the rise of IoT and automation, the demand for these components has surged, significantly affecting user repurchase behaviors.

The reason behind this trend is clear: modern industrial processes require precision and reliability, and outdated equipment can lead to downtime and inefficiencies. As a result, operators are compelled to replace their gear more frequently to ensure smooth operations. This high frequency of procurement not only demands better supply chain management but also necessitates strongafter-sales services and customer support.

Innovating to Improve Repurchase Rates

To maintain a high repurchase rate, manufacturers must innovate by focusing on quality, reliability, and customer experience. For instance, embedding advanced diagnostics and maintenance features into their products can extend the lifespan and reduce maintenance costs, making them more attractive to users. Additionally, implementing a robust customer relationship management (CRM) system can help in identifying recurring needs and upselling complementary products.

Enhanced Reliability Features: Incorporating features such as predictive maintenance alerts and enhanced durability into products can significantly improve repurchase rates. Predictive maintenance, for example, allows operators to proactively address potential issues before they cause downtime, ensuring optimal performance and reducing the need for frequent replacements.

Customer Experience Enhancement: Providing excellent post-purchase support through user manuals, online tutorials, and dedicated customer service can build trust and loyalty. Regular updates and software improvements can also keep customers engaged and encourage them to revisit the brand for future needs.

Contrast with Traditional Methods

Traditionally, manufacturers focused on product quality and pricing to retain customers. However, in the current landscape, these strategies are no longer sufficient. Traditional methods often overlook the importance of customer engagement and after-sales support in fostering long-term relationships. As a result, many manufacturers are seeing a decline in repurchase rates, especially among high-frequency procurement categories.

In contrast, innovative solutions such as predictive maintenance and integrated CRM systems have shown significant success in boosting repurchase rates. For example, a leading instrumentation company that adopted predictive maintenance saw a 25% increase in repurchase rates within six months. Similarly, another firm that implemented a CRM system tailored to managing high-frequency procurement categories witnessed a 15% rise in its repurchase rates.

Case Study: A Success Story

Let's consider a case study of XYZ Instruments, a prominent player in the instrumentation industry. XYZ adopted a multi-faceted strategy to enhance its repurchase rate. They began by integrating predictive maintenance features into their sensors, which allowed for proactive alerts and timely replacements. Additionally, they developed a comprehensive CRM system that tracked customer needs and provided tailored recommendations for complementary products.

The results were remarkable. Within one year, XYZ Instruments reported a 30% increase in repurchase rates for high-frequency procurement categories. Their customer satisfaction scores also improved by 20%, demonstrating the effectiveness of their innovative approach.

Conclusion

Understanding and addressing the repurchase rate dynamics in the instrumentation industry, particularly for high-frequency procurement categories, is essential for manufacturers and suppliers. By adopting innovative solutions such as predictive maintenance and enhancing customer experience through robust CRM systems, companies can significantly boost their repurchase rates and stabilize long-term business relationships. As technology continues to evolve, staying ahead of the curve by embracing these innovative strategies will be crucial for competitiveness in the industry.