Precautions for Using Pressure Instruments: Overpressure Protection, Shock Resistance, and Antifreeze

Pressure instruments are essential tools in numerous industrial, scientific, and mechanical applications. Ensuring their accuracy and reliability is critical, especially when dealing with dynamic and potentially dangerous environments. Overpressure protection, shock resistance, and antifreeze protection are key considerations. Understanding these aspects helps maintain the longevity and efficiency of these instruments.

One, Keyword Analysis

Pressure instruments, widely used across industries, need to be protected from various stresses. Overpressure protection is crucial to prevent damage from excessive pressure. Shock resistance is essential in environments with frequent vibrations or impacts. Antifreeze protection ensures the instruments remain functional in cold conditions. These keywords frequently appear in relevant discussions and technical specifications, making them integral to the design and maintenance of pressure instruments.

Two, Problem Analysis

One of the primary issues with pressure instruments is their susceptibility to overpressure damage. In industrial settings, sudden spikes in pressure can occur due to process fluctuations, human error, or equipment malfunctions. These situations can lead to instrument failure, which not only impacts operational safety but also results in significant financial losses.

Another significant problem is the challenge of shock resistance. High-pressure systems often operate in environments with constant vibrations, which can cause the instrument components to shift or break. This can lead to false readings or complete instrument failure, compromising operational reliability.

Lastly, antifreeze protection is critical in regions with extreme cold. In cold environments, the fluids inside the pressure instrument can freeze, leading to blockages and damage to the components. This issue can disrupt operations and cause downtime, which is often costly.

Three, Impact Population

These issues affect a wide range of industries, including but not limited to:

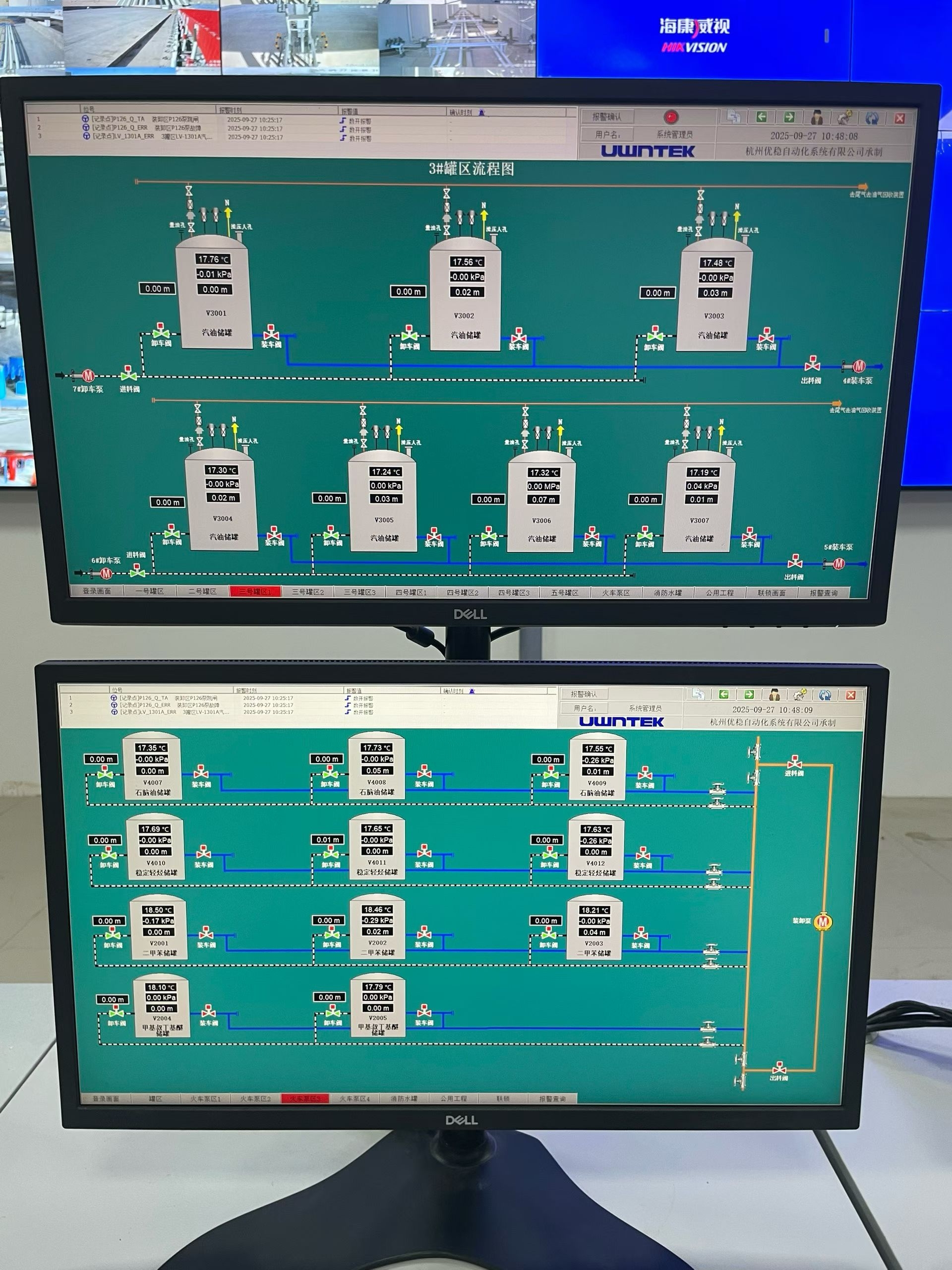

- Petroleum and Gas: In fracking, drilling, and production, any instrument failure can lead to major operational disruptions and safety hazards.

- Chemical Manufacturing: Accurate and reliable pressure measurements are essential for controlling reactions and ensuring product quality.

- Aerospace: In aircraft and rocket engines, precise pressure measurements are crucial for engine performance and safety.

- Automotive Industry: Pressure sensors are vital for monitoring and maintaining engine and brake systems.

- Construction and Mining: These instruments are used to monitor and control the pressure in pipes and pumps, ensuring safe and efficient operations.

Four, Solving the Problems

Overpressure Protection:

- Implementing pressure relief valves can prevent catastrophic failure by automatically releasing excess pressure.

- Using oversize sensors can provide a greater margin of safety, ensuring the instrument can handle occasional spikes in pressure without damage.

- Conducting regular maintenance and calibration checks can help detect and address potential issues early.

Shock Resistance:

- Vibration dampening mounts can offset the impact of vibrations, protecting the instrument’s components from shifting and breaking.

- Encapsulated components and robust enclosures can provide additional protection against shock and impact.

- Employing underwater shock absorbers in aquatic environments can ensure continued operation during turbulent conditions.

Antifreeze Protection:

- Using antifreeze fluids that have a lower freezing point can prevent fluid blockages in cold conditions.

- Installing heaters or thermostats to maintain fluid temperature can ensure the instrument continues to function correctly.

- Performing regular service checks to ensure that antifreeze levels and heaters are functioning properly can prevent costly downtime.

Five, Handling Abnormal Situations

When encountering overpressure incidents, immediate action must be taken to prevent further damage. This involves identifying the source of the excessive pressure and ensuring it is addressed promptly.

For shock resistance issues, detailed logs of operational environments should be maintained to better understand the sources of vibration and impact. Utilizing diagnostic tools and sensor data can help pinpoint areas that require reinforcement or changes.

When dealing with antifreeze failures, regular inspections and maintenance schedules should include checking the antifreeze levels and heater functionality. Employing automated monitoring systems can provide early warnings for potential issues, allowing for prompt corrective action.

By understanding the key issues and taking proactive measures, the lifespan and performance of pressure instruments can be significantly enhanced, ensuring safe and efficient operations across various industries.