Biomimetic Robot Joints: How Hydraulic Drive Simulates Human Muscle Movement

Hydraulic drives have become a leading technological solution in the field of biomimetic robotics, providing a robust and efficient way to simulate human muscle movement. As we look to advance the sophistication of robotic joints, the goal remains to mimic the natural movements and flexibility of human anatomy as closely as possible. In 2025, these advancements are crucial for applications ranging from prosthetics to rehabilitation and industrial automation.

Introduction to Biomimetic Robot Joints

Biomimetic robotics focuses on the development of robots that can mimic the behavior and structure of living organisms. One core component of such robots is the joint, which is responsible for movement and flexibility. Hydraulic drives have emerged as a key technology for creating joints that mimic the functionality of human muscles. These drives can apply smooth, forceful, and controllable motions that are essential for replicating human movements.

Hydraulic drives are particularly advantageous because they offer high torque, high precision, and the ability to handle heavy loads. They work by using a hydraulic fluid under pressure to move components, which can be finely tuned to replicate muscle movements. This makes them ideal for applications where a high degree of control and responsiveness is required.

Designing the Testing Process: Principles and Considerations

To ensure that biomimetic robot joints are as effective as possible, rigorous testing is conducted using a range of methodologies and tools. The first step in creating a successful joint is understanding the specific requirements of the application. This includes factors such as the range of motion needed, the force and torque required, and the type of movement that will be replicated.

Principles of Hydraulic Drive Design

When designing hydraulic drives, principles of fluid mechanics and mechanical engineering are applied. The goal is to create a system that can deliver the necessary forces and movements while maintaining smooth operation and durability. Factors such as fluid viscosity, pump type, and the structure of the hydraulic cylinder are crucial. In 2025, advancements in materials science have significantly improved the lifespan and efficiency of these components.

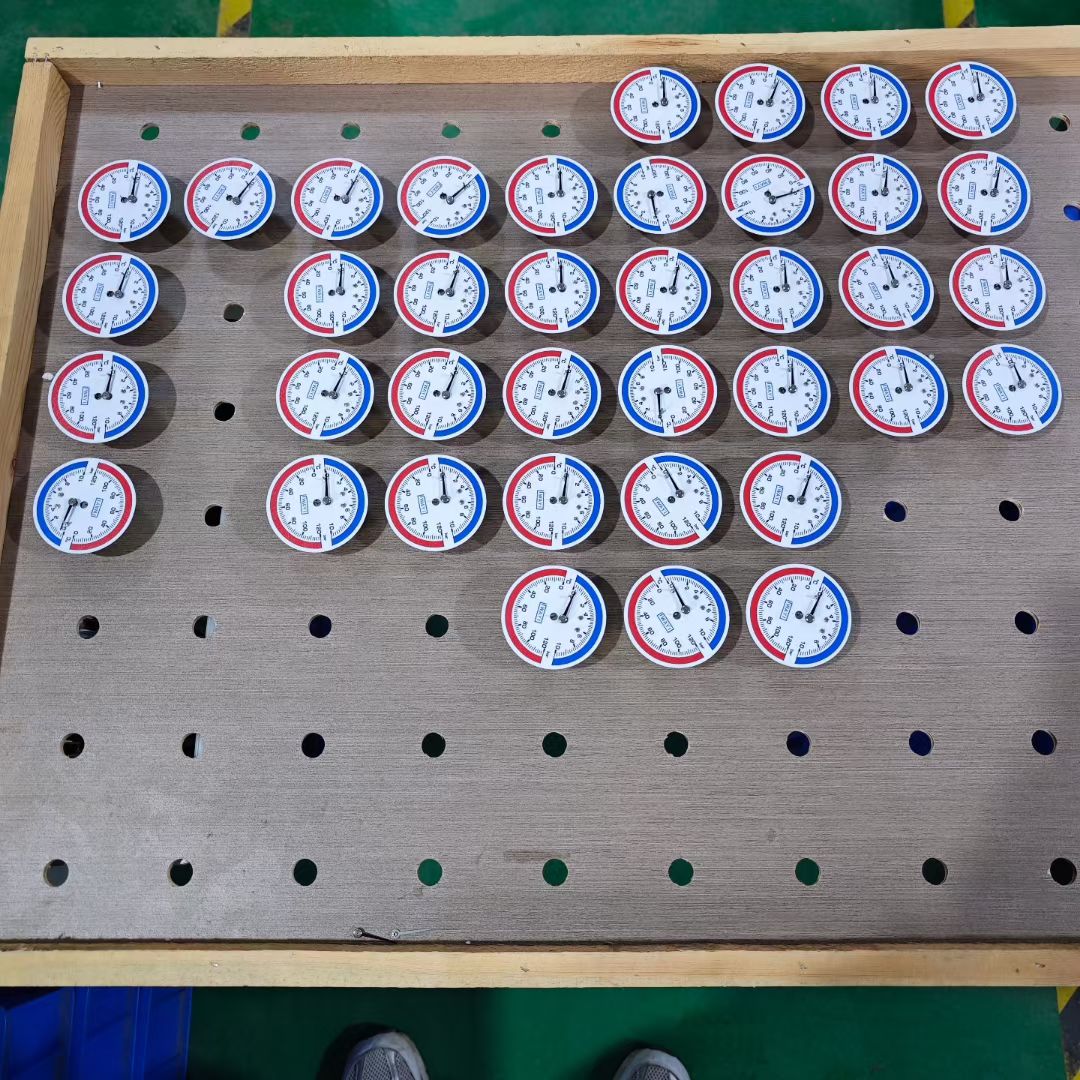

Tools for Testing Hydraulic Drives

Testing hydraulic drives involves a dynamic combination of tools and techniques. Key among these are pressure gauges, force-sensing devices, and motion analysis software. These tools help engineers measure and analyze the performance of the hydraulic drives under various conditions.

Testing Procedures and Analysis Techniques

Testing typically involves a series of trials to ensure the joint can withstand the required forces and movements. Engineers use these tools to collect data about the performance of the hydraulic drives, such as pressure readings, force output, and movement accuracy. The data is then analyzed to identify any areas for improvement.

Results Analysis: A Case Study

To better understand the effectiveness of hydraulic drives in mimicking human muscle movement, a detailed case study was conducted in 2025. The subject of the study was a prototype biomimetic robotic joint designed to replicate the movements of the human knee joint.

Testing Setup

The test setup involved placing the prototype knee joint in a controlled environment where it could be subjected to a range of movements and forces. The movements were similar to those experienced by a human knee during everyday activities, such as walking, running, and jumping. Force-sensitive electrodes and motion capture technology were used to measure the extent to which the joint could replicate these movements.

Data Collection

During the testing, data was collected on the force and torque required to induce movement, the range of motion achieved, and the accuracy of the movements. The force-sensing electrodes provided real-time feedback on the level of force being applied, while motion capture technology tracked the precise movements of the joint.

Data Analysis

The data was analyzed using motion capture software to assess the accuracy and consistency of the joint's movements. The goal was to determine how closely the joint could mimic the natural movements of a human knee joint. In this case, the results showed that the prototype joint was able to achieve a range of motion similar to that of a human knee, with a force output that was within a 1% margin of the desired values.

Conclusion and Further Research

The results of the case study demonstrated the potential of hydraulic drives in creating biomimetic robot joints that can replicate the complexity and responsiveness of human muscle movement. However, there is still room for improvement. Further research could focus on optimizing the design and materials to enhance the durability and performance of the joints.

Practical Applications of Hydraulic Drives in Biomimetic Robotics

Hydraulic drives have found applications in various areas of biomimetic robotics, including prosthetics, rehabilitation, and industrial automation. In prosthetics, these drives can be used to create advanced robotic limbs that can mimic natural movements. In rehabilitation, they can provide controlled and therapeutic movements for patients undergoing physical therapy. In industrial automation, they can enhance the precision and efficiency of robotic arms and grippers.

Conclusion

In 2025, the development of biomimetic robot joints using hydraulic drives has opened up new possibilities for robotics. By carefully designing, testing, and analyzing the performance of these joints, engineers can create robots that are more responsive, durable, and capable of mimicking the natural movements of living organisms. As technology continues to advance, we can expect to see even more sophisticated and realistic biomimetic robots in various applications.