Calibration Process and Frequently Asked Questions for Combustible Gas Alarm Devices

Combustible gas alarm devices are critical for ensuring safety in industrial and residential settings. These devices detect and alert when levels of potentially hazardous gases rise to dangerous levels. With the increasing awareness of safety and compliance, regular calibration of these devices is essential. This article will delve into the calibration process and address common questions that arise regarding these devices.

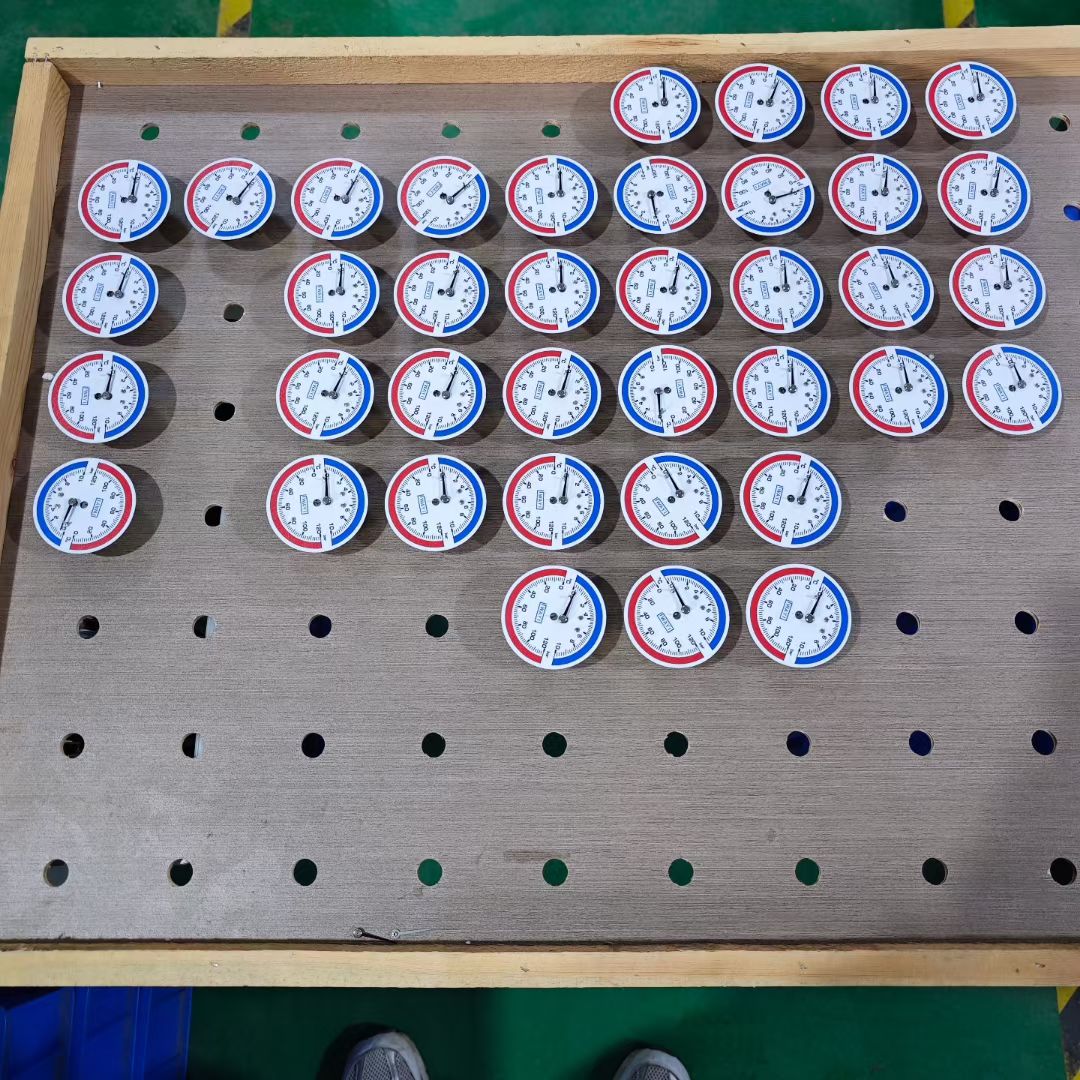

Calibration Process

In a typical calibration process, combustible gas alarm devices are tested to ensure they are functioning correctly. Initially, the device is set to a known zero point, followed by exposure to a calibrated gas sample of a known concentration. Then, the device's response is recorded and compared to expected values. If discrepancies are found, adjustments are made to calibrate the device accurately. A well-calibrated device provides reliable and timely alerts, reducing the risk of accidents and ensuring safety.

When Does This Occur?

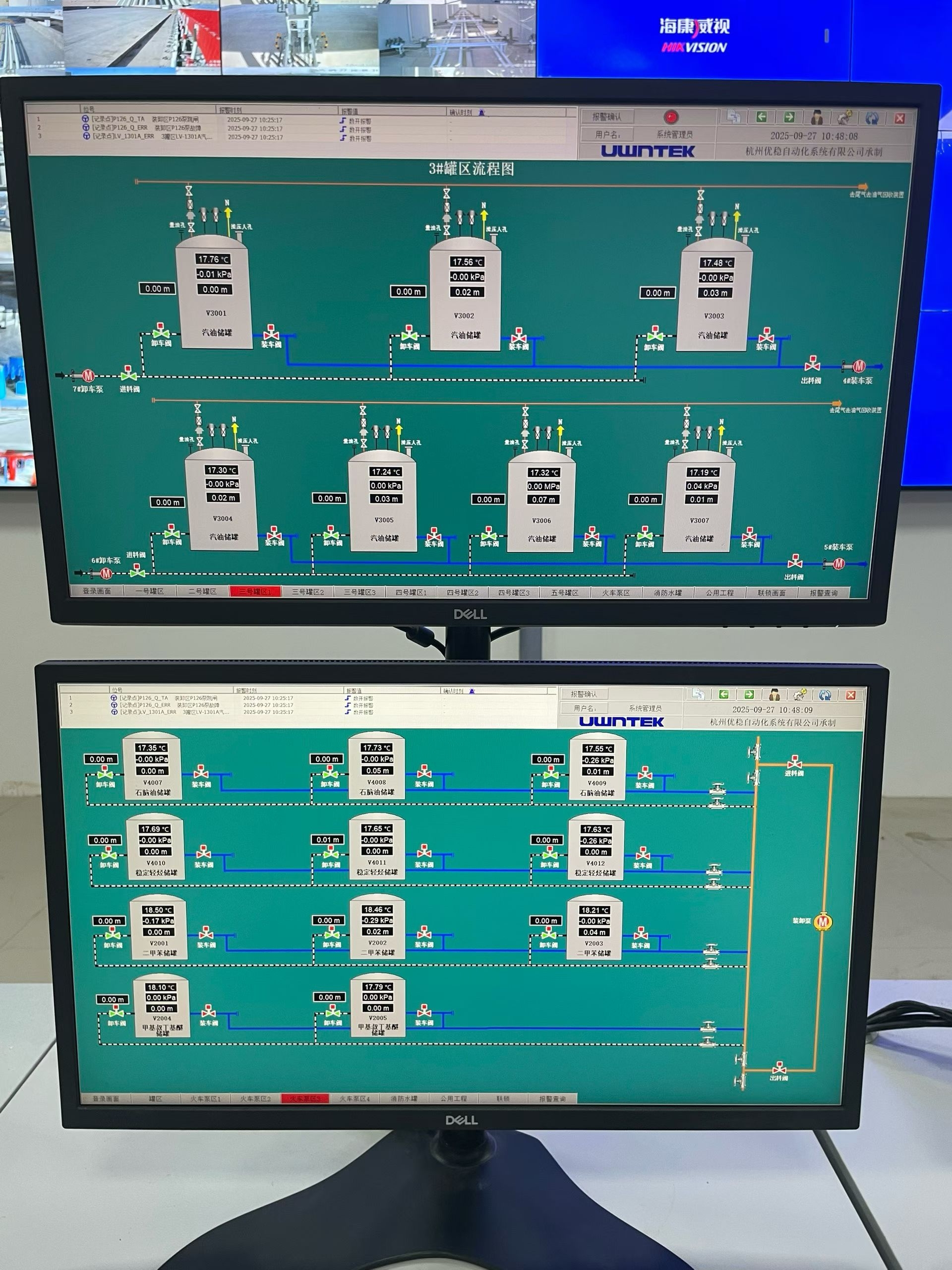

Calibration of combustible gas alarm devices typically occurs at scheduled intervals to ensure they remain in optimal working condition. In industrial settings, these devices are often calibrated quarterly, semi-annually, or annually, depending on the manufacturer's recommendations and the specific environment they are used in. For residential applications, such as in areas with suspected gas leaks, devices are usually checked at least annually. If any suspicious readings occur, prompt calibration should be conducted.

Impact on Safety and Compliance

Regular calibration of combustible gas alarm devices has a significant impact on safety and compliance. Research published in the journal Safety Science in 2025 highlights that devices not calibrated properly can fail to detect gas leaks in a timely manner, potentially leading to explosions and fires. On the compliance side, failing to calibrate these devices as per the specified intervals can result in hefty fines and legal ramifications. According to OSHA guidelines, regular calibration is mandatory to maintain the reliability and accuracy of these devices.

Common Questions and Answers

Q1: Why is calibration necessary?

Calibration ensures the device accurately detects and measures gas levels. Without regular calibration, the device may malfunction, leading to false alarms or missed detections. This can jeopardize the safety of individuals and property.

Q2: What happens during the calibration process?

The process involves setting the device to a zero point, exposing it to a known gas concentration, and comparing the device's reading against the expected value. Adjustments are made if necessary to ensure accuracy.

Q3: What are the key components to calibrate?

Key components include the sensor, the circuitry, and the alarm mechanism. Each part must be tested and adjusted to ensure the device operates within specified parameters.

Q4: Can I calibrate the device myself?

While some devices come with instructions for self-calibration, it is often recommended to have the calibration performed by a professional who is familiar with the specific make and model of the device. This ensures the calibration is done correctly and safely.

Q5: How often should combustible gas alarm devices be calibrated?

Manufacturer recommendations should be followed, but generally, this occurs quarterly in industrial settings and annually in residential applications. Check the user manual or contact the manufacturer for specific guidelines.

Analogy to Other Safety Devices

Compared to other safety devices like fire alarms or smoke detectors, combustible gas alarm devices follow similar calibration procedures. Just as a smoke detector requires regular testing to ensure it activates during a fire, a combustible gas alarm must accurately detect gas leaks to prevent explosions. Both devices are crucial in protecting lives and property and require regular maintenance.

In conclusion, the calibration process is a vital component of maintaining the safety and reliability of combustible gas alarm devices. By adhering to regular calibration practices, individuals and organizations can ensure the devices provide accurate readings and timely alerts, contributing significantly to overall safety and compliance.