Multi Brand Instrument Data Unified Access SCADA System Solution

Navigating the complex world of industrial automation requires a reliable and unified system to manage multi-brand data. Enter the SCADA (Supervisory Control and Data Acquisition) system solution, a powerful tool that consolidates data from various instruments and devices into a single, accessible platform. This solution is crucial for maintaining operational efficiency and ensuring accurate real-time monitoring across diverse industrial settings. With a strong focus on integration and data uniformity, the 2025 multi-brand instrument data unified access SCADA system offers unprecedented levels of productivity and control.

Bridging the Gap Between Diverse Instruments

One of the primary challenges in industrial automation is managing data from instruments made by different manufacturers. Each brand often has its own proprietary system, making it difficult to create a cohesive and integrated data management process. The 2025 multi-brand instrument data unified access SCADA system addresses this issue by offering a standardized platform that can seamlessly integrate data from multiple brands. It provides a robust framework for data collection, analysis, and visualization, ensuring that all critical information is readily available for informed decision-making.

Setting Up the SCADA System

Configuring the SCADA system involves several key steps to ensure optimal performance and seamless integration. First, device connectivity setup is critical. This involves connecting the SCADA system to the various instruments and ensuring that data exchange is smooth and secure. Driver installation is another important step, as the system needs to support the communication protocols of each brand’s device. Network configuration is necessary to secure the network and optimize data transmission. Lastly, user interface customization allows for a user-friendly experience, tailoring the system to meet specific operational needs.

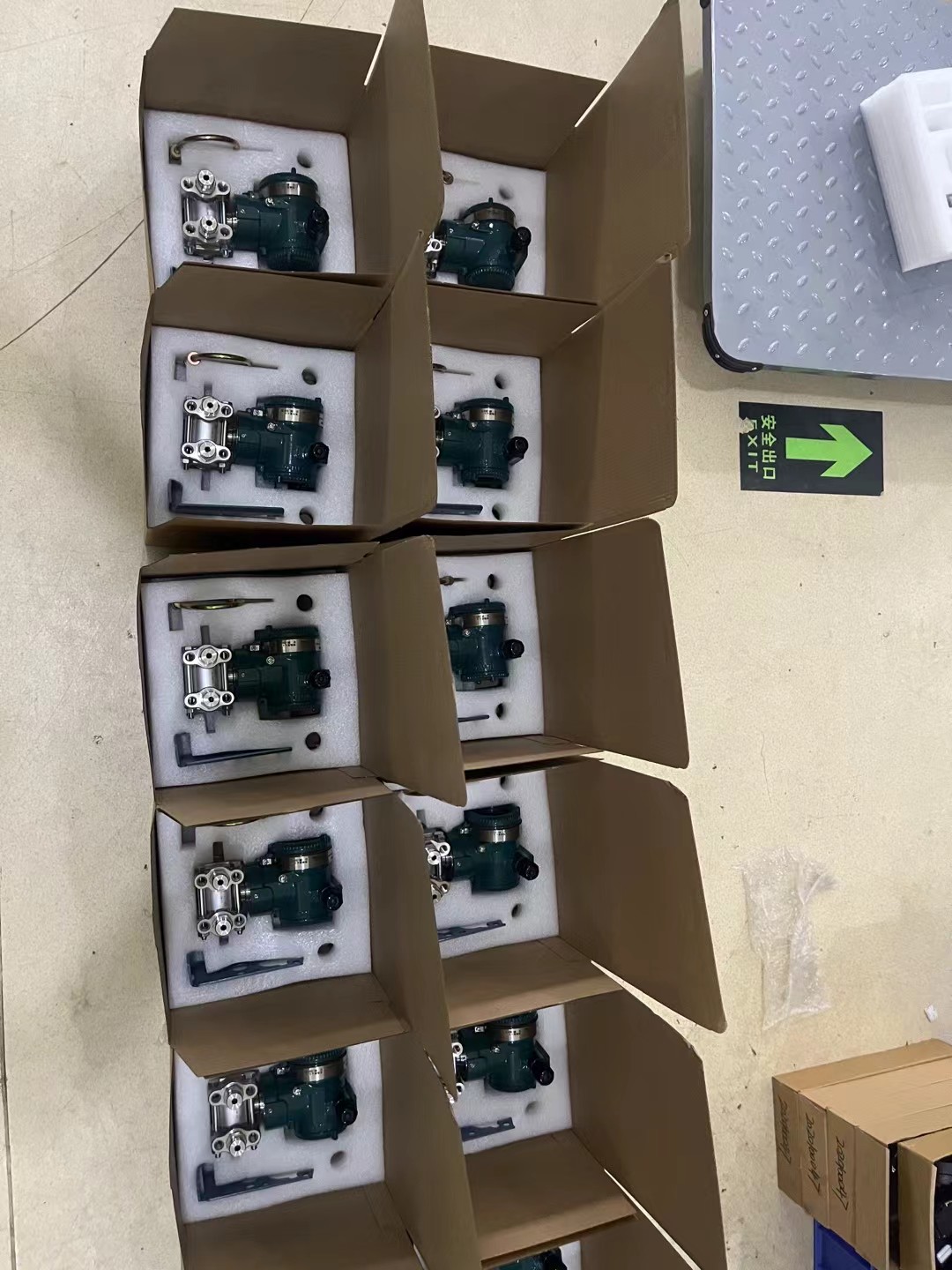

A Practical Example: Implementing the SCADA System in a Chemical Plant

Consider a chemical plant where multiple brands of instruments are in use, ranging from sensors to controllers. Before implementing the SCADA system, the plant’s engineering team needs to understand how each brand’s instrument works and what data is being collected. They begin by setting up the SCADA system, ensuring that all devices are correctly connected and that drivers are installed for seamless communication.

Monitoring the plant’s operations start after the system is configured. A data dashboard provides real-time updates on various critical parameters, such as temperature, pressure, and flow rates. The SCADA system also consolidates historical data, making it easy to track trends and identify any anomalies. For instance, a drop in pressure levels could trigger immediate alerts, enabling the team to take proactive measures, thereby preventing potential downtime and ensuring operational safety.

Feedback from Users and Industry Experts

Feedback from early adopters of the 2025 multi-brand instrument data unified access SCADA system has been overwhelmingly positive.Many users appreciate the system’s ability to streamline operations and improve overall efficiency. Industry experts also commend the solution for its robust security features, which protect sensitive industrial data while ensuring reliable and secure communication between instruments.

In the field, the system has been particularly useful in environments where instruments from different brands are widely used, such as in refineries and manufacturing plants. Users report significant improvements in data accuracy, faster response times to anomalies, and more streamlined maintenance processes. This has not only enhanced operational efficiency but also reduced operational costs by minimizing downtime and optimizing resources.

Mastering the Use of the SCADA System

To fully leverage the 2025 multi-brand instrument data unified access SCADA system, users should approach it with a methodical and thorough understanding. Here are a few tips for mastering the system:

- Thorough training: Invest in comprehensive training programs to ensure that all team members understand the system’s capabilities and functionalities.

- Regular updates: Stay informed about the latest software updates and security patches to maintain optimal system performance.

- Continuous monitoring: Regularly review and analyze data to identify trends and potential issues, ensuring that the SCADA system continues to meet your evolving needs.

In conclusion, the 2025 multi-brand instrument data unified access SCADA system is a game-changer for industrial automation. By providing a standardized platform for managing diverse instruments, it simplifies operations, enhances accuracy, and ensures compliance with regulatory standards. Whether you’re in the chemical, oil and gas, or manufacturing industries, this solution offers a robust and flexible way to unify your data and drive operational excellence.