How to Judge the Quality of Instruments and Meters from Technical Indicators

In the world of precision measurement, the quality of instruments and meters is paramount. Whether you're in an engineering lab, a manufacturing plant, or a healthcare facility, the reliability and accuracy of your measuring devices can significantly impact the success of your operations. In 2025, ensuring that you are using high-quality instruments is crucial for maintaining standards and ensuring safety. This article will guide you through the process of evaluating the quality of instruments and meters based on technical indicators and provide you with practical examples and insights.

Understanding the Technical Indicators

The first step in judging the quality of an instrument is to understand the key technical indicators. These indicators are crucial in determining the performance and reliability of a measuring device. They include:

- Accuracy: This measures how close the reading is to the true value. Accuracy is often expressed as a percentage of the range of the device.

- Resolution: This indicates the smallest increment that the instrument can detect and display. High resolution ensures that you can perform precise measurements.

- Precision: Precision refers to the consistency of repeated measurements. A high-precision instrument will give you the same reading multiple times under the same conditions.

- Range: The range of a device is the difference between the lowest and highest values it can measure. Ensuring that your instrument has the appropriate range is critical.

- Reproducibility: This is the ability of a reading to be obtained consistently over time and under different conditions.

Understanding these indicators is crucial for selecting the right instrument for your specific needs.

Configuring and Evaluating Instruments

Once you have a good grasp of the technical indicators, the next step is to configure and evaluate your instrument. This involves setting up the instrument, calibrating it, and ensuring that it meets all the necessary standards.

- Setup and Calibration: Proper setup involves selecting the correct model, connecting it to power, and entering relevant setup parameters like measure range and scale. Calibration involves using known standards to adjust the instrument's readings to meet specified accuracy levels.

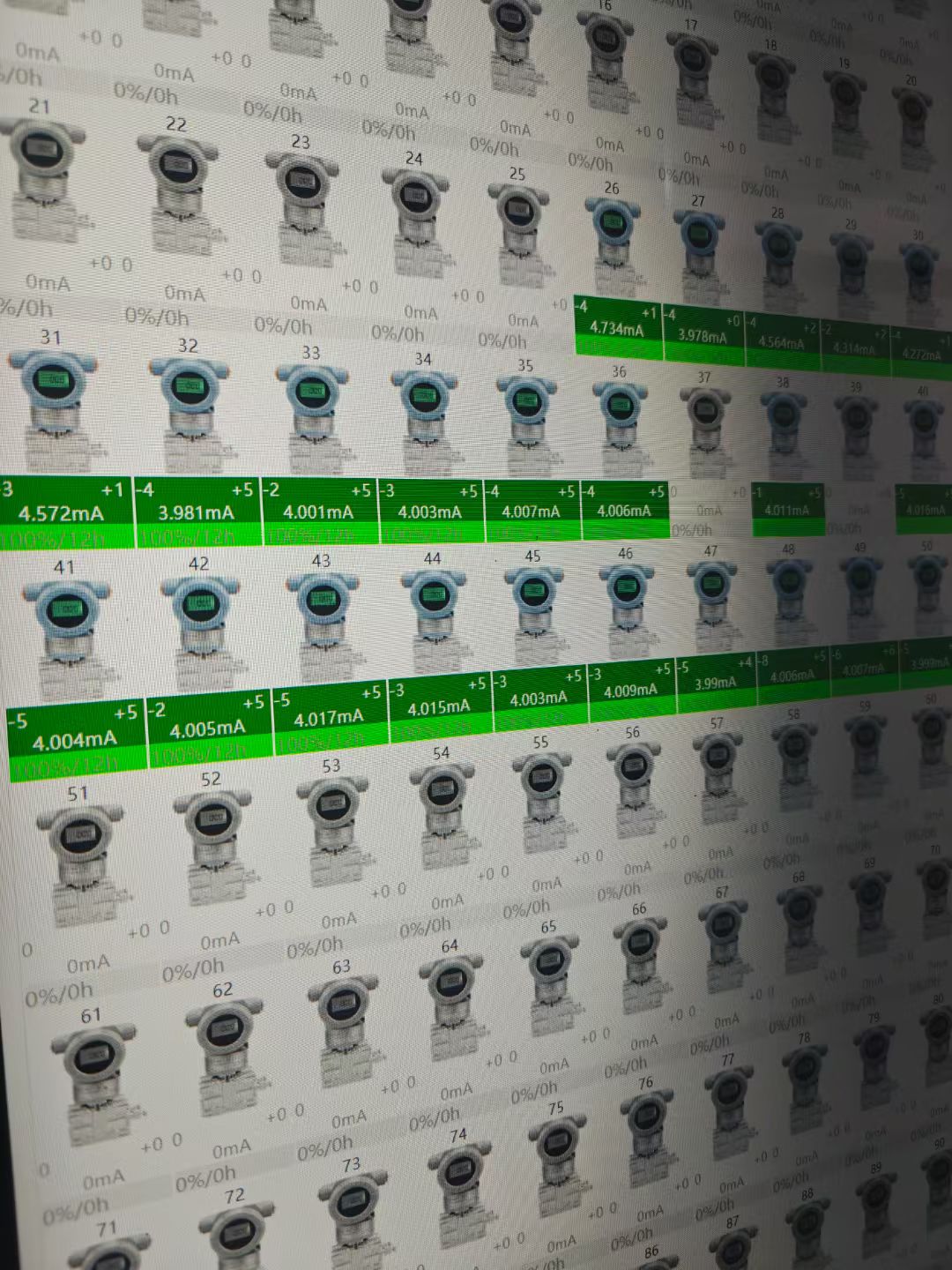

- Performance Testing: After calibration, perform tests using known values to verify that the instrument is performing as expected. This includes testing accuracy, precision, and reproducibility.

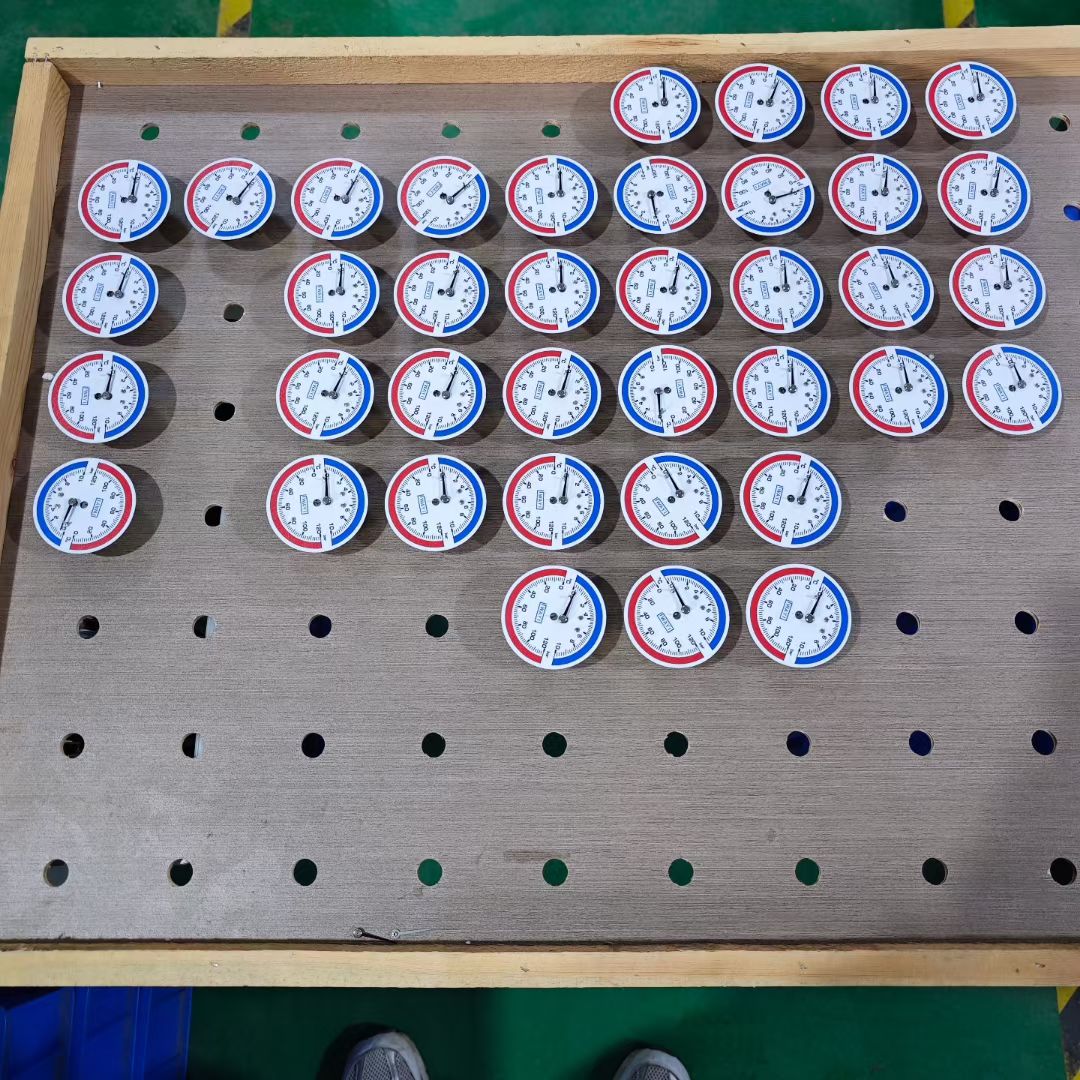

For instance, if you are working with a temperature sensor, you might use a temperature standard to check the instrument's accuracy. Similarly, for a pressure gauge, you would use a pressure calibrator to ensure it reads accurately across the range.

Practical Case Studies and User Feedback

Let’s look at a practical case study where a company evaluated its instruments and meters using the outlined criteria.

Example 1: Temperature Sensor Calibration

A manufacturing company needed to ensure that their temperature sensors were reliable for maintaining strict temperature controls in their production lines. They first checked the accuracy by comparing the sensor readings with a known standard in a controlled environment. They then tested the sensor’s precision by performing multiple readings under identical conditions. Finally, they verified the reproducibility by comparing readings over a period of time.

Example 2: Pressure Gauge Validation

In a different case, a medical facility needed to ensure that their pressure gauges provided accurate readings for patient monitoring. They calibrated the gauges using high-precision pressure calibrators to adjust the readings to exact values. Next, they tested the gauges under varying conditions to check their precision and reproducibility. User feedback indicated that the gauges were performing well, reducing the risk of misdiagnosis and improving patient safety.

Conclusion

Judging the quality of instruments and meters based on technical indicators is a critical process that ensures accurate and reliable measurements. By understanding accuracy, resolution, precision, range, and reproducibility, configuring and evaluating these instruments, and gathering user feedback, you can make informed decisions about your measuring devices.

In 2025, the stakes for precision measurement are higher than ever, making it essential to invest in quality instruments and regularly evaluate their performance. By following the methods outlined in this article, you can maintain the highest standards in your operations and ensure the safety and success of your projects.