Guidelines for Choosing Explosion Proof Grades and Matching Scenarios for Instruments and Meters

In the continuously evolving industrial landscape, safety and reliability are paramount, especially in high-risk environments such as petroleum refineries, chemical plants, and hazardous gas storage facilities. Explosion-proof instruments and meters play a critical role in ensuring that these environments remain safe and operational. Choosing the appropriate explosion-proof grade and matching it with the correct application scenario is essential to maintain the highest standards of safety and efficiency. This article will explore the key aspects of selecting explosion-proof grades and scenarios, ensuring that industrial setups meet both regulatory requirements and operational needs in a 2025 timeframe.

Industry Background

Safety regulations and standards are crucial in industries where flammable gases and vapors are present. Standards like the ATEX (Atmospheric Explosions Prevention for explosive atmospheres) in Europe and NEC (National Electrical Code) in the U.S. underscore the importance of explosion-proof devices. Explosion-proof grades classify devices based on their ability to contain or prevent arcs and/or sparks that could cause explosions. For example, Class I, Division 1, and Group A, B, C, or D ratings are used to categorize potentially explosive atmospheres. Understanding these classifications is key to selecting the right instruments and meters.

Technological Drivers

Modern technological advancements have significantly enhanced the accuracy and reliability of explosion-proof equipment. Advanced materials such as aluminum and stainless steel are used in crafting robust and durable devices. Additionally, intelligent sensors and digital displays offer enhanced data capture and remote monitoring capabilities, which are crucial in ensuring continuous safety and efficiency. These innovations not only meet regulatory requirements but also enhance operational convenience.

Applications (3 Main Scenarios)

Petroleum Refineries

In petroleum refineries, the presence of volatile organic compounds (VOCs) and hydrocarbons makes the environment inherently hazardous. Here, explosion-proof instruments and meters are used to monitor pressure, temperature, and flow rates in various processes. For instance, high-end silicon-based pressure sensors are used in critical applications, ensuring that any changes in pressure are accurately detected and recorded. This helps in maintaining the stability of the refining process and preventing any catastrophic failures.

Chemical Plants

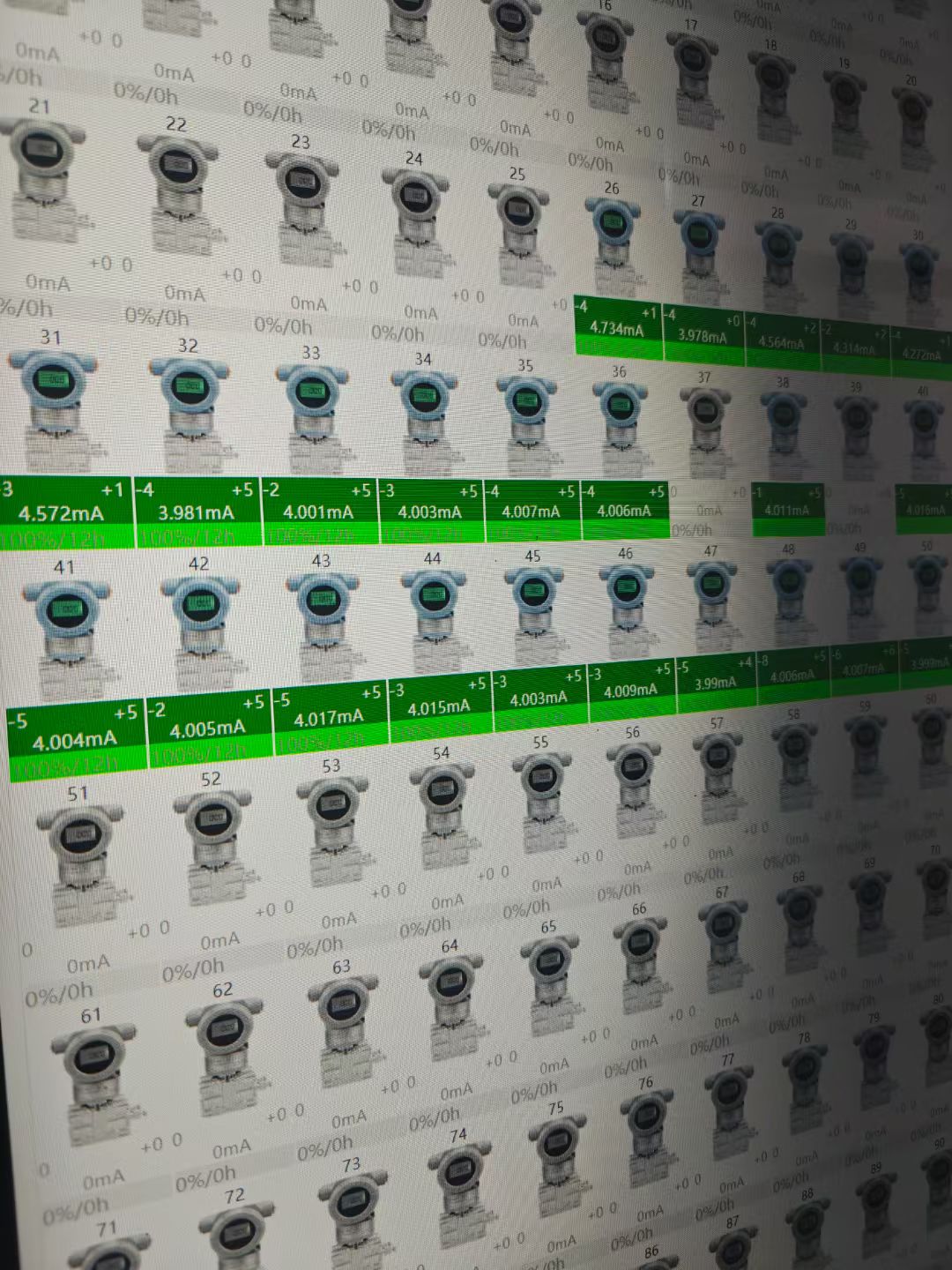

Chemical plants often involve the handling of highly reactive chemicals and flammable substances. In these environments, explosion-proof meters and instruments are used to measure temperature, level, pressure, and flow. Smart sensors like** capacitive pressure transmitters** can provide real-time data on these parameters, ensuring that operators can quickly respond to any potential issues. For example, in a scenario where there's an increase in temperature, the system can trigger alerts and take corrective actions, minimizing the risk of an explosion.

Hazardous Gas Storage Facilities

Storage facilities for flammable gases pose a significant risk of explosion. Here, explosion-proof indicators are essential to ensure the safe storage and handling of these gases. These devices detect any anomalies in temperature, pressure, or level and trigger alarms if necessary. In addition, remote monitoring systems can be integrated with these indicators to provide real-time data to operators, enabling them to take proactive measures.

Competitive Landscape

The market for explosion-proof instruments and meters is well-established, with major players like Honeywell, Yokogawa, and Siemens dominating the space. These companies offer comprehensive solutions that cater to a wide range of industrial applications. Honeywell, for instance, provides a range of explosion-proof meters and indicators that meet the stringent safety standards. Yokogawa is known for its advanced smart sensor technology, which enhances the accuracy and reliability of data. Siemens offers a diversified portfolio, including equipment for Class I Division 1 and Class II Division 2 environments, ensuring that customers have access to the latest technology.

Future Outlook

The future of explosion-proof instrumentation is expected to be characterized by further technological advancements. Wireless sensor networks are likely to become more prevalent, enabling real-time data transmission and remote monitoring. Artificial intelligence and machine learning can also play a role in predictive maintenance, helping to identify potential issues before they become serious. Additionally, sustainable materials and designs will become more prominent, addressing both safety and environmental concerns. As industry standards evolve, the focus will remain on enhancing safety and efficiency while minimizing downtime.

By understanding the 2025 guidelines, industries can ensure that their explosion-proof instruments and meters are not only compliant with regulatory standards but also highly effective in their respective environments. This will ultimately contribute to a safer and more efficient industrial landscape.