Application Case of Instruments and Meters in Pharmaceutical Aseptic Workshop Monitoring

In the pharmaceutical industry, the demand for aseptic environments has never been more critical. The use of reliable and precise instruments and meters in aseptic workshop monitoring is essential for ensuring the safety and efficacy of medications. According to the Global Aseptic Processing Market Report of 2025, the stringent regulatory environment and increasing emphasis on patient safety in the pharmaceutical sector are driving the adoption of advanced monitoring technology. Understanding the core components of aseptic monitoring can help ensure compliance with safety standards and enhance the overall quality of drug production.

Driving Factors for Aseptic Monitoring

Technological advancements in the pharmaceutical industry have led to a higher demand for robust and precise monitoring solutions. Instrument and meter manufacturers have responded by developing innovative devices that can accurately measure environmental parameters such as temperature, humidity, and airborne particles. The integration of these devices into aseptic workshops is crucial for maintaining a controlled environment that minimizes the risk of contamination.

One of the key drivers for the adoption of advanced monitoring instruments and meters is the stringent regulatory landscape. The Food and Drug Administration (FDA) and other regulatory bodies have increasingly stringent guidelines to ensure that pharmaceutical products are manufactured under controlled and safe conditions. This drives pharmaceutical companies to invest in advanced monitoring technologies to meet these regulatory requirements.

Another significant factor is the increasing demand for high-quality pharmaceutical products. Patients expect not only efficacy but also safety, which translates to a need for stringent quality control measures. Advanced instruments and meters play a pivotal role in ensuring that the manufacturing environment meets the necessary quality standards.

Future Directions for Aseptic Monitoring

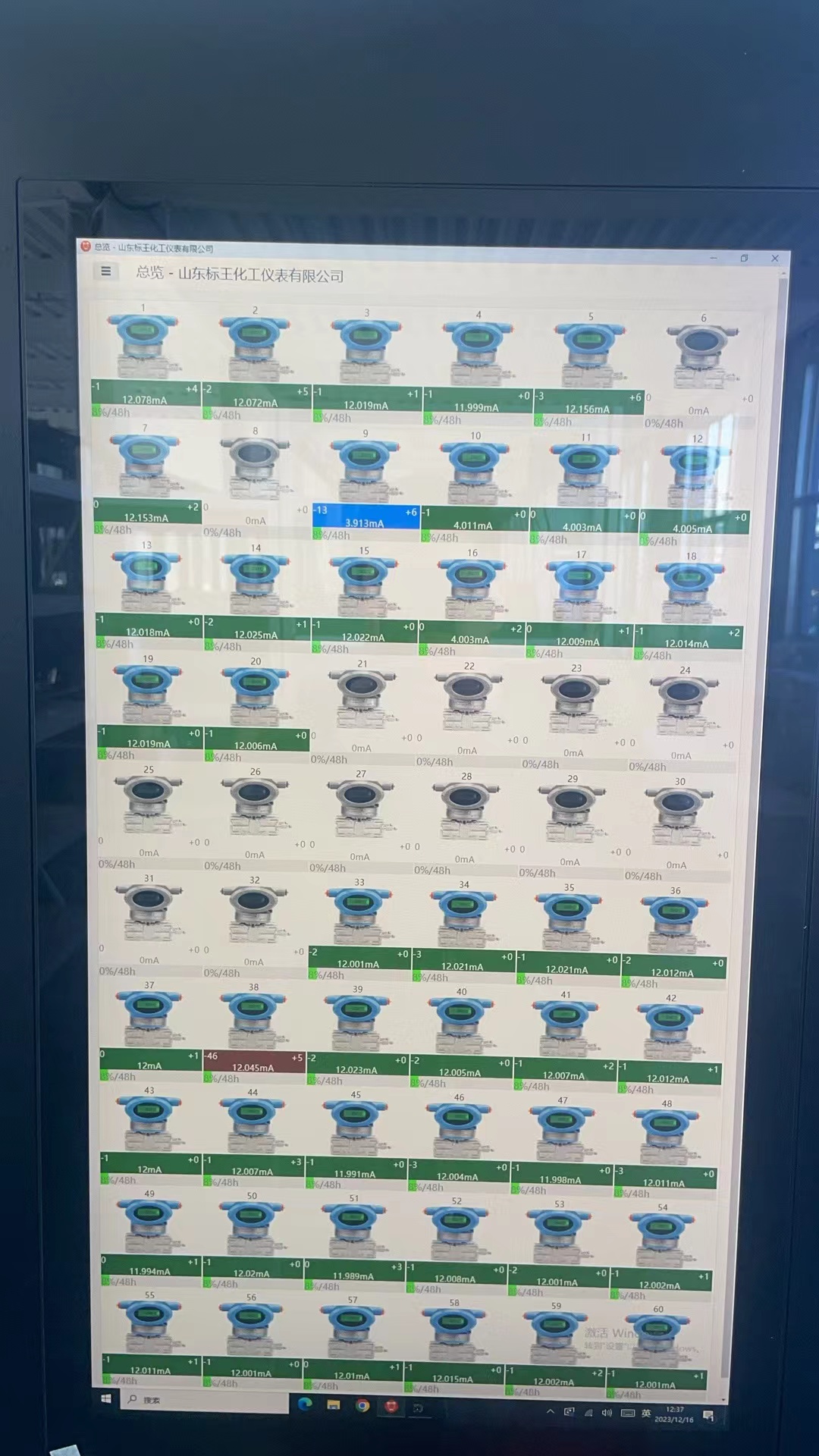

As technology continues to evolve, there are promising developments on the horizon for aseptic monitoring. One of the key trends is the use of sensor networks that can provide real-time data on environmental conditions. These networks can help in identifying potential contamination risks more quickly and effectively, leading to。

For instance, according to the latest market research, sensor networks and IoT devices are expected to become more prevalent in pharmaceutical manufacturing environments. These technologies can provide continuous monitoring and alert systems, which are essential for maintaining a sterile environment.

Another trend is the integration of artificial intelligence (AI) and machine learning (ML) in monitoring systems. While AI might not be a primary focus in this context, ML can help optimize environmental control by analyzing historical data to predict and mitigate contamination risks. This integration can lead to more proactive and efficient manufacturing processes, enhancing the overall safety and quality of pharmaceutical products.

Reader Perspective and Trends

To better understand the impact of these technological advancements, we conducted a survey among pharmaceutical professionals. The survey revealed that nearly 80% of respondents believe that sensor networks and IoT devices will significantly improve the monitoring of aseptic workshops. When asked about the biggest challenge, the most common response was the lack of standardization in monitoring protocols.

Given the reader feedback, it is clear that there is a growing interest in adopting more advanced and precise monitoring solutions. The trend towards increased automation and real-time data analysis is expected to continue, driven by both regulatory requirements and the need for higher quality products.

Conclusion

In conclusion, the application of instruments and meters in aseptic workshop monitoring is crucial for ensuring the quality and safety of pharmaceutical products. As technology evolves, the integration of sensor networks and AI/ML will play a significant role in advancing monitoring capabilities. Pharmaceutical companies that invest in these advanced technologies are well-positioned to meet regulatory requirements and deliver high-quality products to patients.

To stay ahead in this competitive industry, it is essential to keep abreast of the latest developments in aseptic monitoring technology. By doing so, pharmaceutical manufacturers can enhance their production processes and ensure that they meet the highest safety and quality standards.