How Can Instruments and Meters Assist High-End Equipment in Achieving Independent Controllability? Case Study

In the rapidly evolving landscape of technological innovation, instruments and meters have become essential tools for ensuring the high-performance and reliability of complex industrial equipment. These devices play a pivotal role in achieving independent controllability, which is crucial for maintaining operational efficiency and safety. To achieve this, instruments and meters must be finely tuned to monitor, measure, and control parameters within the equipment, ensuring seamless and precise operation. In 2025, the integration of advanced instruments and meters in high-end systems has become a cornerstone of modern engineering, enabling sophisticated control mechanisms and precise adjustments.

Instrumentation Analysis

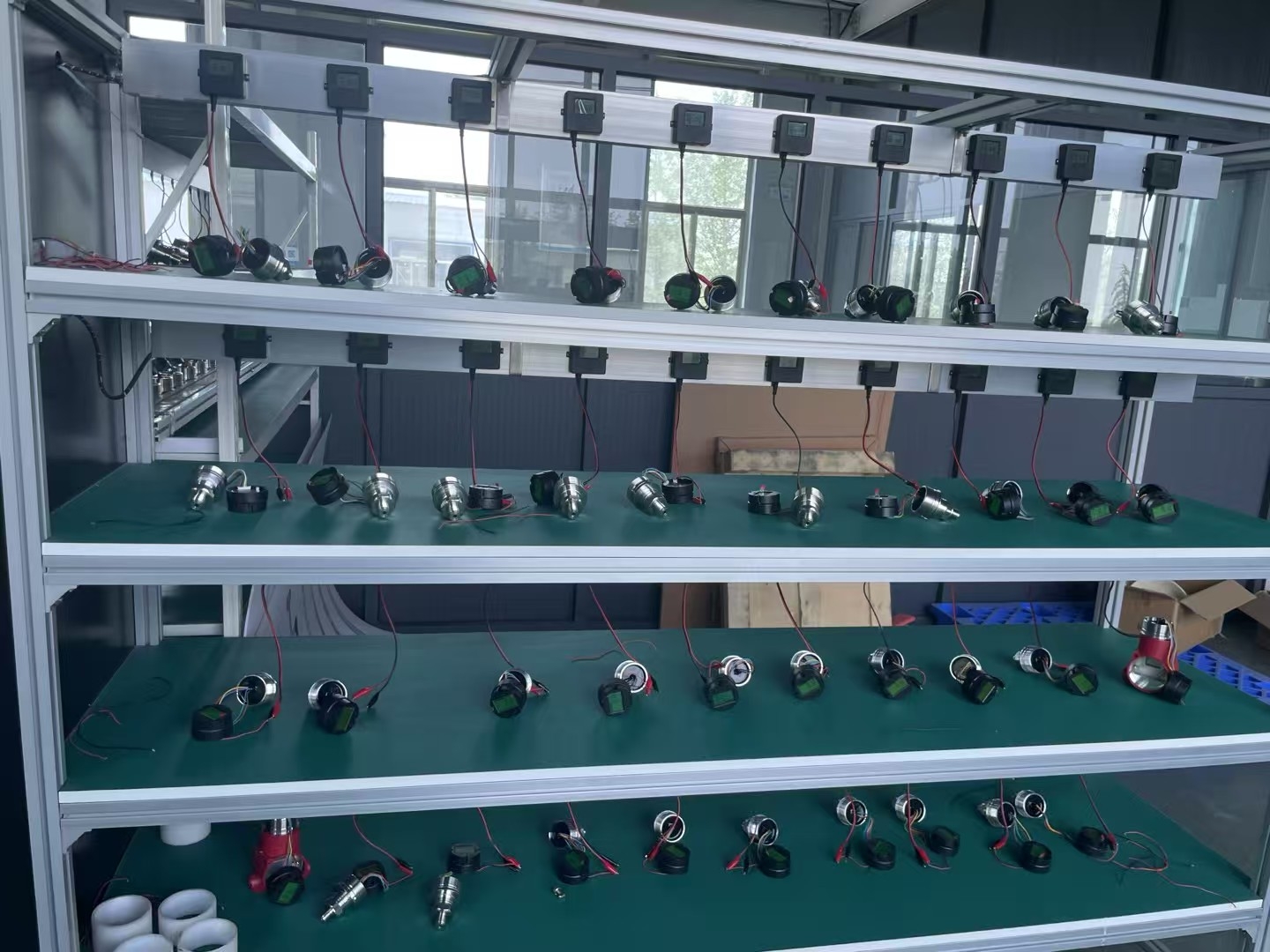

To understand how instruments and meters contribute to high-end equipment, it is essential to analyze the components involved. Instruments are devices that provide information by measuring some physical quantity, while meters display these measurements in a readable format. Both are crucial for real-time monitoring and control. In 2025, these devices have become increasingly sophisticated, incorporating advanced sensors, microprocessors, and wireless communication technologies. This sophistication allows for accurate and timely data acquisition, processing, and transmission, ensuring that the system is always under optimal control.

When Do These Problems Arise?

Problems with instrumentation and meter performance can arise in various situations. Typically, these issues can manifest during the commissioning and routine maintenance of equipment. For instance, a malfunctioning temperature sensor in a chemical reactor can lead to critical safety breaches, while a faulty pressure gauge in a hydraulic system can result in equipment damage or operational failures. Furthermore, older instruments may become less accurate over time due to wear and tear,。 This degradation can lead to increased downtime and higher operational costs, making regular calibration and maintenance essential.

What Is the Impact Range?

The impact of failures in instrumentation and metering systems is extensive and can range from minor inconvenience to catastrophic operational failures. From a safety perspective, malfunctioning instruments can lead to hazardous situations, such as over-temperature or over-pressure conditions, which can result in safety breaches and potential injuries or fatalities. Economically, these failures can increase operational costs through increased maintenance and repair expenses. Additionally, regulatory non-compliance resulting from inaccurate measurements can lead to hefty fines and reputational damage. In high-end industries like aerospace and pharmaceuticals, where precision is paramount, the consequences of such issues can be particularly severe.

Solving the Problem: A Multi-Faceted Approach

To address these challenges, a comprehensive approach is necessary. Firstly, ensuring the use of high-quality instruments and meters is crucial. High-end equipment should be equipped with state-of-the-art sensors and displays that are calibrated for optimal performance. Secondly, regular calibration and maintenance schedules should be strictly followed. This involves checking the accuracy and reliability of instruments periodically to ensure they meet the required standards. Thirdly, implementing robust diagnostic tools and monitoring software can predict potential degradation or failure before it occurs. By integrating these tools, engineers can take proactive measures to prevent failures and maintain system integrity.

Case Study: A Real-World Application

Let us consider a case study involving a cutting-edge smart manufacturing facility that utilizes advanced instruments and meters for precise control. This facility produces electronic components that require tight tolerances and consistent performance. In one instance, a fault in the temperature control system caused fluctuations in the production process, leading to a batch of defective parts. Upon investigation, it was discovered that the thermocouples had aged and become less accurate over time. This problem was mitigated by upgrading the thermocouples and implementing a rigorous calibration schedule. As a result, the facility was able to regain consistent production outputs and improve overall quality control.

Conclusion: The Role of Instruments and Meters in High-End Equipment

The role of instruments and meters in achieving independent controllability in high-end equipment cannot be overstated. They are the backbone of modern industrial systems, ensuring precision, safety, and reliability. By adopting best practices in the selection, installation, and maintenance of these devices, engineers can significantly enhance the performance and efficiency of high-end equipment. In 2025 and beyond, the continuous evolution of instrumentation technology heralds a future where equipment can operate at higher levels of autonomy and efficiency, paving the way for greater innovation and progress.